Equipment and method for collecting industrially cultivated pelagic eggs

A factory-like, buoyant technology, which is applied in the field of collection facilities for buoyant eggs in breeding ponds, achieves good results, low cost of transformation, and is easy to popularize and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following describes in detail the structure and use method of the facility of the present invention through embodiments and drawings:

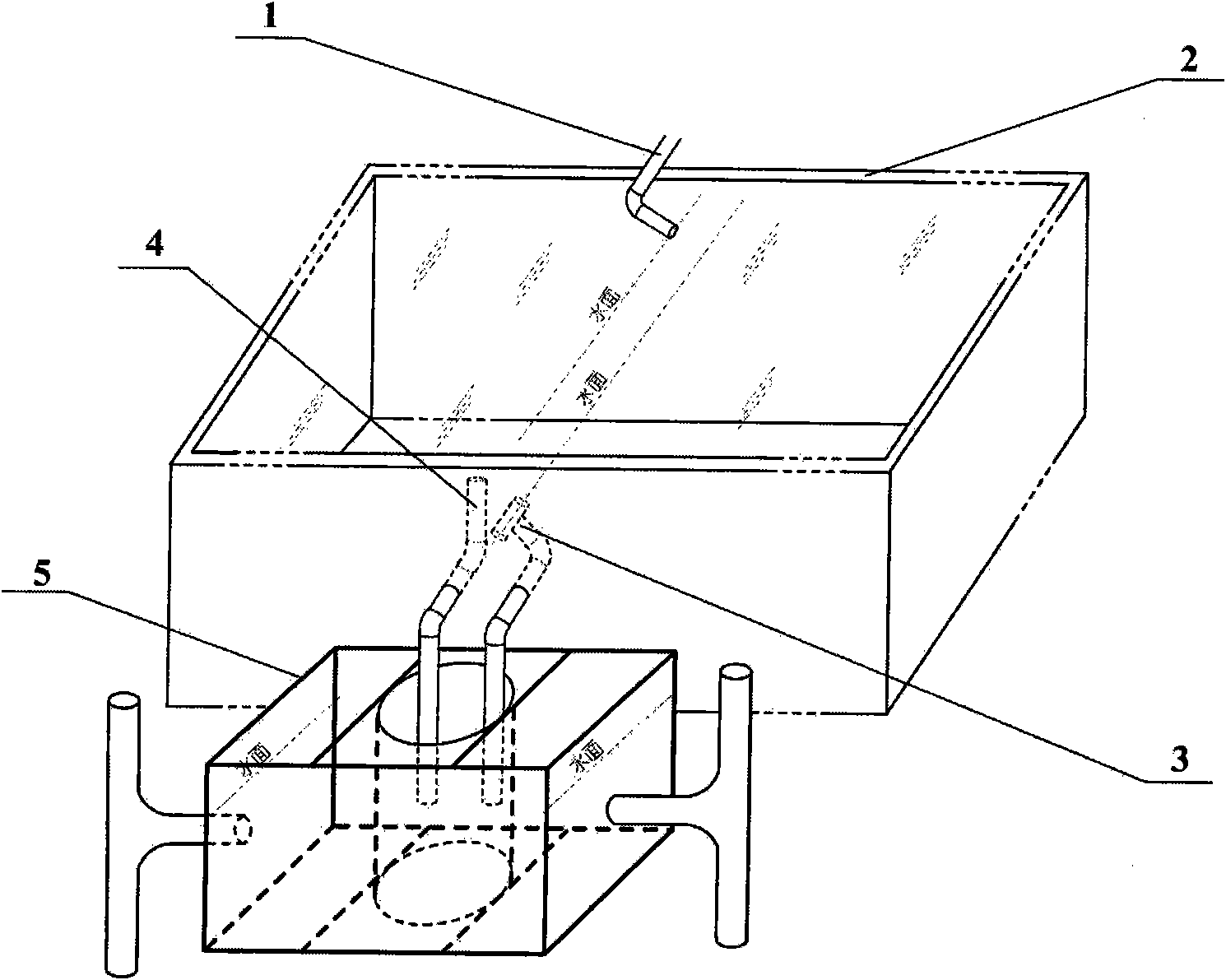

[0023] See figure 1 , Its facilities include: water inlet pipe 1, drainage pipe 3, anti-overflow drainage pipe 4, glass tank 5, egg collection cage 15.

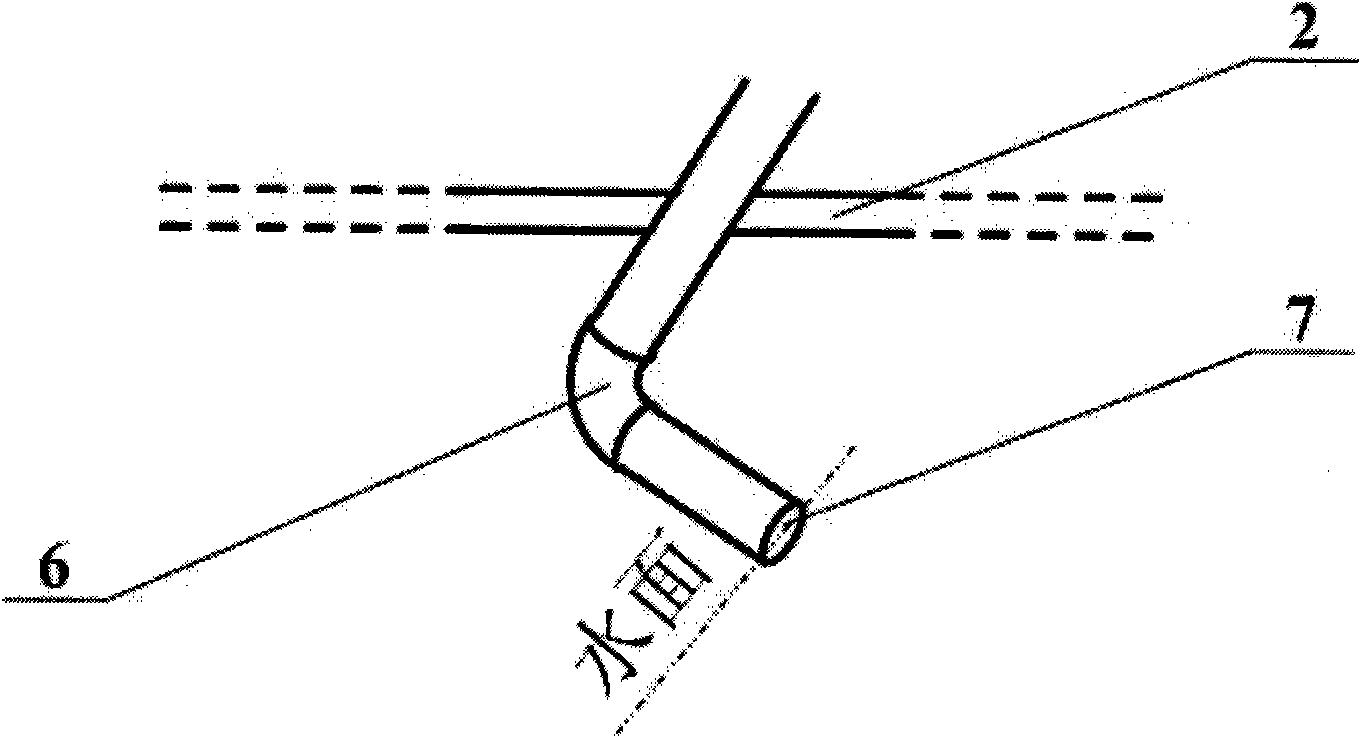

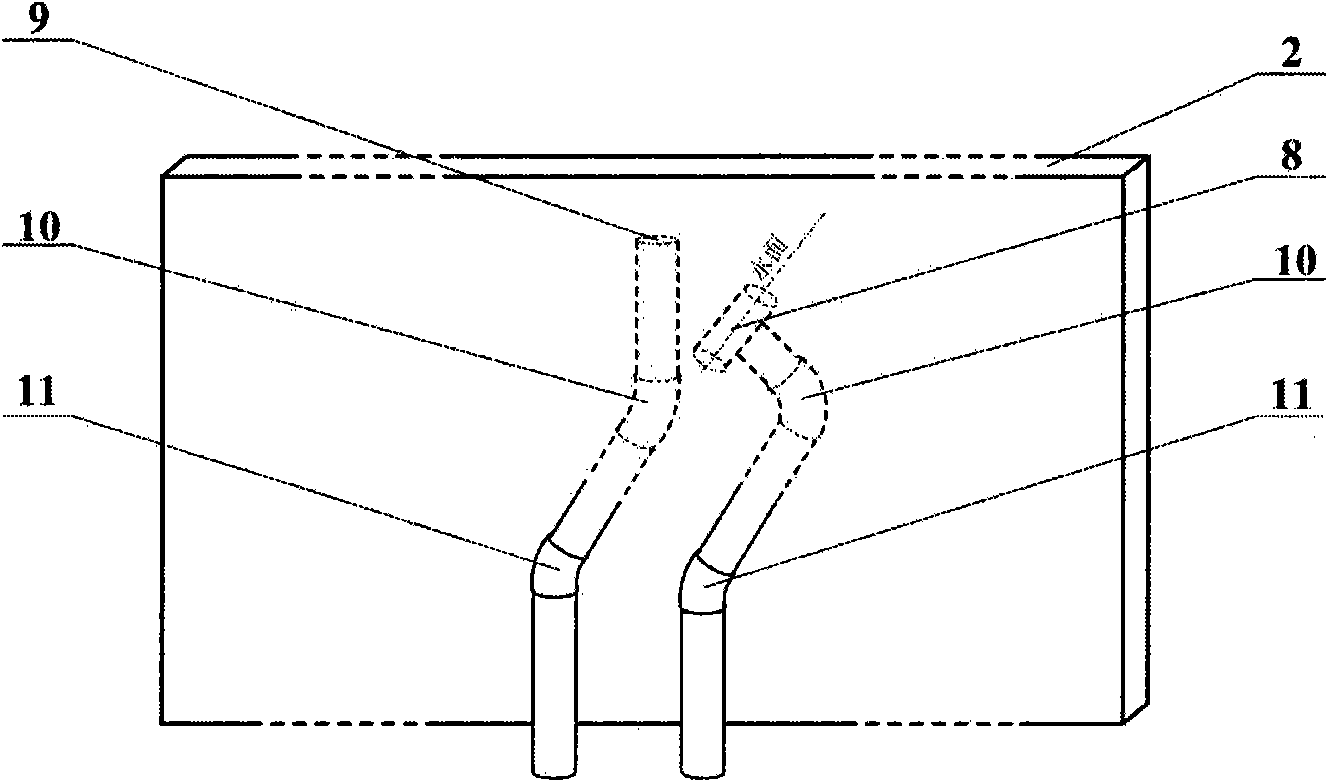

[0024] The water inlet pipe 1 is located in the middle position above a wall of the breeding pond. The treated aquaculture water flows into the pond through the water inlet pipe 1, and the water inlet pipe outlet 7 is adjusted by the movable elbow A6 to keep the position on the water surface. Half is below the water surface in the pool, and half is above the water surface (see figure 2 ), in order to prevent the influent water from flowing too much and impacting the water surface of the breeding pond and causing mechanical damage to the floating eggs. figure 1 with image 3 As shown, the drainage pipe 3 and the anti-overflow drainage pipe 4 are located at the middle and high position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com