Cement waterproofing material and preparation method thereof

A waterproof material and cement technology, which is applied in the field of cement materials, can solve problems such as complex construction process and unsafe operation, and achieve the effect of simple production process, wide range of raw materials and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

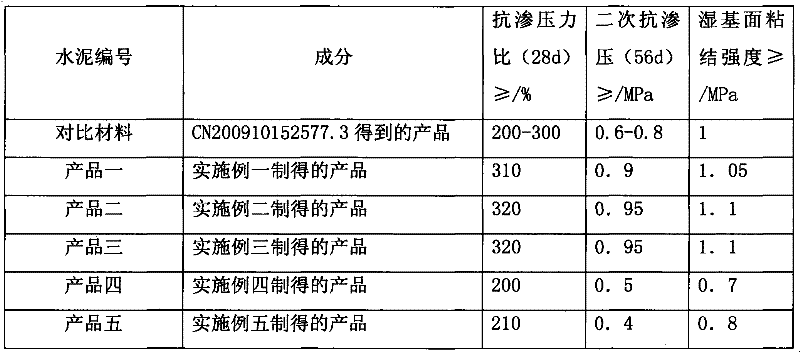

Examples

Embodiment 1

[0028] The preparation process of the cement waterproof material of the present invention is as follows:

[0029] The preparation of the active mixture M: the content of each component in percentage by weight: ferric chloride 20%, sodium carbonate 20%, magnesium carbonate 5%, calcium carbonate 5%, strontium carbonate 0.5, and the rest are magnesium chloride for ingredients; Sodium, magnesium carbonate, calcium carbonate, strontium carbonate and magnesium chloride are all powders with a particle size of 270-500 mesh. After mixing the ingredients, stir evenly for 5-10 minutes to form an active mixture M;

[0030] Pour the refined quartz sand into the mixer and stir continuously. Add Portland cement during the mixing process. The particle size of the refined quartz sand is 0.1-0.5mm, and the particle size of the Portland cement powder is 270-500 mesh. , And then slowly add the above-mentioned active mixture M, and stir evenly for 5-10 minutes to obtain the cement waterproof material; ...

Embodiment 2

[0032] The weight percentages of the ingredients when preparing the active mixture M are: ferric chloride 30%, sodium carbonate 30%, magnesium carbonate 10%, calcium carbonate 10%, strontium carbonate 1%, and the rest are magnesium chloride.

[0033] The weight ratio of the three during the preparation of the cement waterproof material is: Portland cement: refined quartz sand: active mixture M=35:70:5.

[0034] The preparation method is the same as in Example 1.

Embodiment 3

[0036] The weight percentage of each component when preparing the active mixture M is: 25% ferric chloride, 25% sodium carbonate, 7% magnesium carbonate, 8% calcium carbonate, 0.8% strontium carbonate, and the rest is magnesium chloride.

[0037] The weight ratio of the three during the preparation of the cement waterproof material is: Portland cement: refined quartz sand: active mixture M=35:70:4.

[0038] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com