Woodenware polishing paint and preparation method thereof

一种木器、聚氨酯改性的技术,应用在高分子化学领域,能够解决价格贵、环境污染大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1: the preparation example of polyurethane modified acrylic resin

[0064] (1) Preparation of monomers containing C=C double bonds and -NHCOO-

[0065] Take by weighing 5.13kg (90mol) methyl isocyanate and 15kg ethyl acetate solvent, add in the reactor that stirrer, reflux condenser, heating control temperature temperature and dripping device are housed, add 0.03kg stannous octoate catalyst, by dropwise adding Slowly add 10.44kg (90mol) of hydroxyethyl acrylate, control the temperature at 40-45°C, and react for 3 hours to obtain 30.6kg of monomers containing C=C double bonds and -NHCOO- with a concentration of 50%.

[0066] (2) In a reaction kettle equipped with a stirring device, a reflux condenser, a heating control temperature and a dropping device, sequentially add a mixed solution consisting of the following components. First add the following component A into the reaction kettle, stir, heat up to the reflux temperature of about 75°C; slowly add the B c...

Embodiment 2

[0081] Embodiment 2: the preparation example of polyurethane modified acrylic resin

[0082] (1) Preparation of monomers containing C=C double bonds and -NHCOO-

[0083] Take by weighing 6.96kg (40mol) toluene diisocyanate (TDI) and 14kg ethyl acetate solvent respectively, add in the reactor that stirrer, reflux condenser, heating temperature control temperature and dropping device are housed, add 0.026kg stannous octoate catalyst , slowly add 5.2kg (40mol) hydroxypropyl acrylate by dropwise, control the temperature at 40-50°C, react for 2 hours, then add 1.84kg (40mol) ethanol, continue to react for 2 hours, and the prepared concentration is 50% 28 kg of monomers containing C=C double bonds and -NHCOO-.

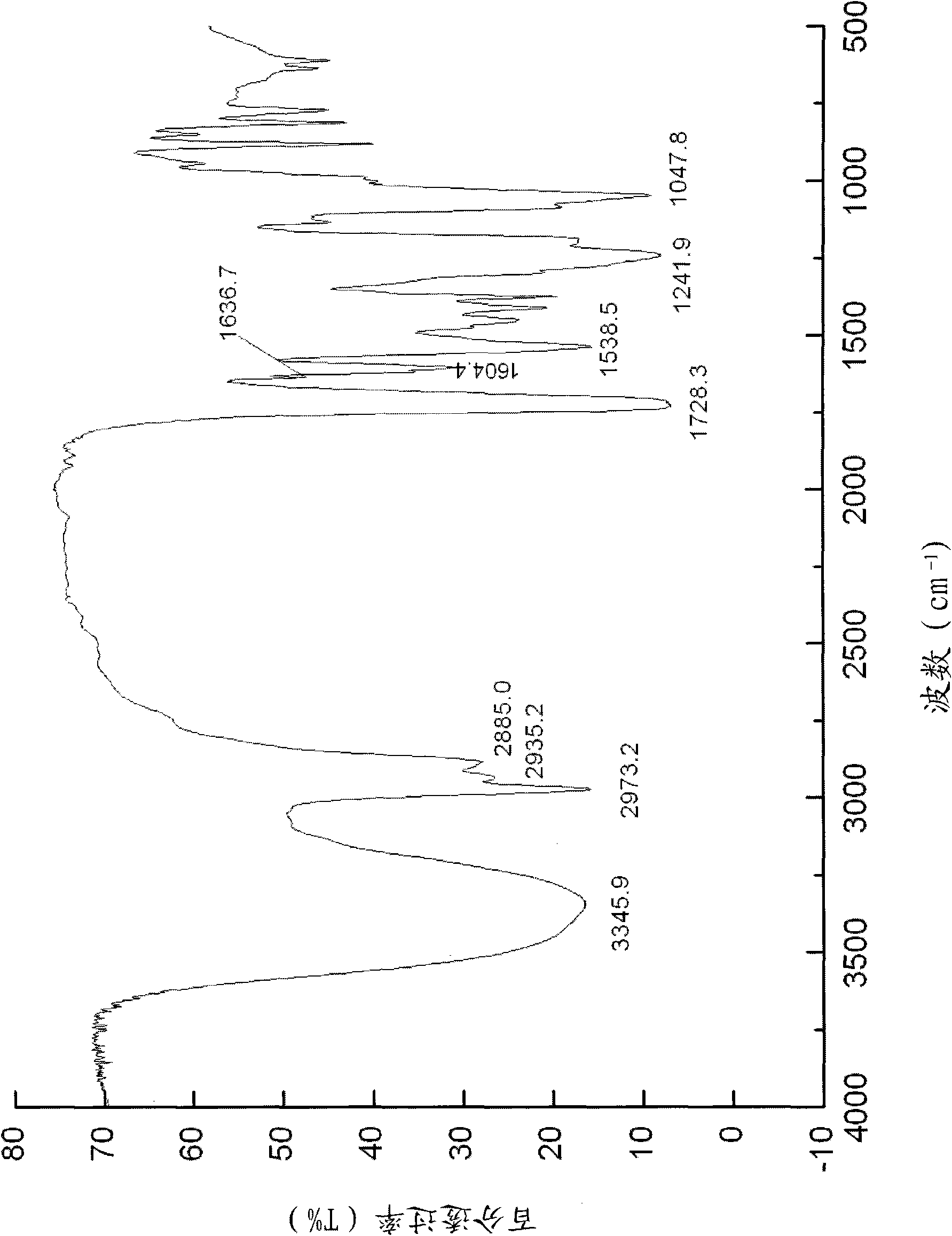

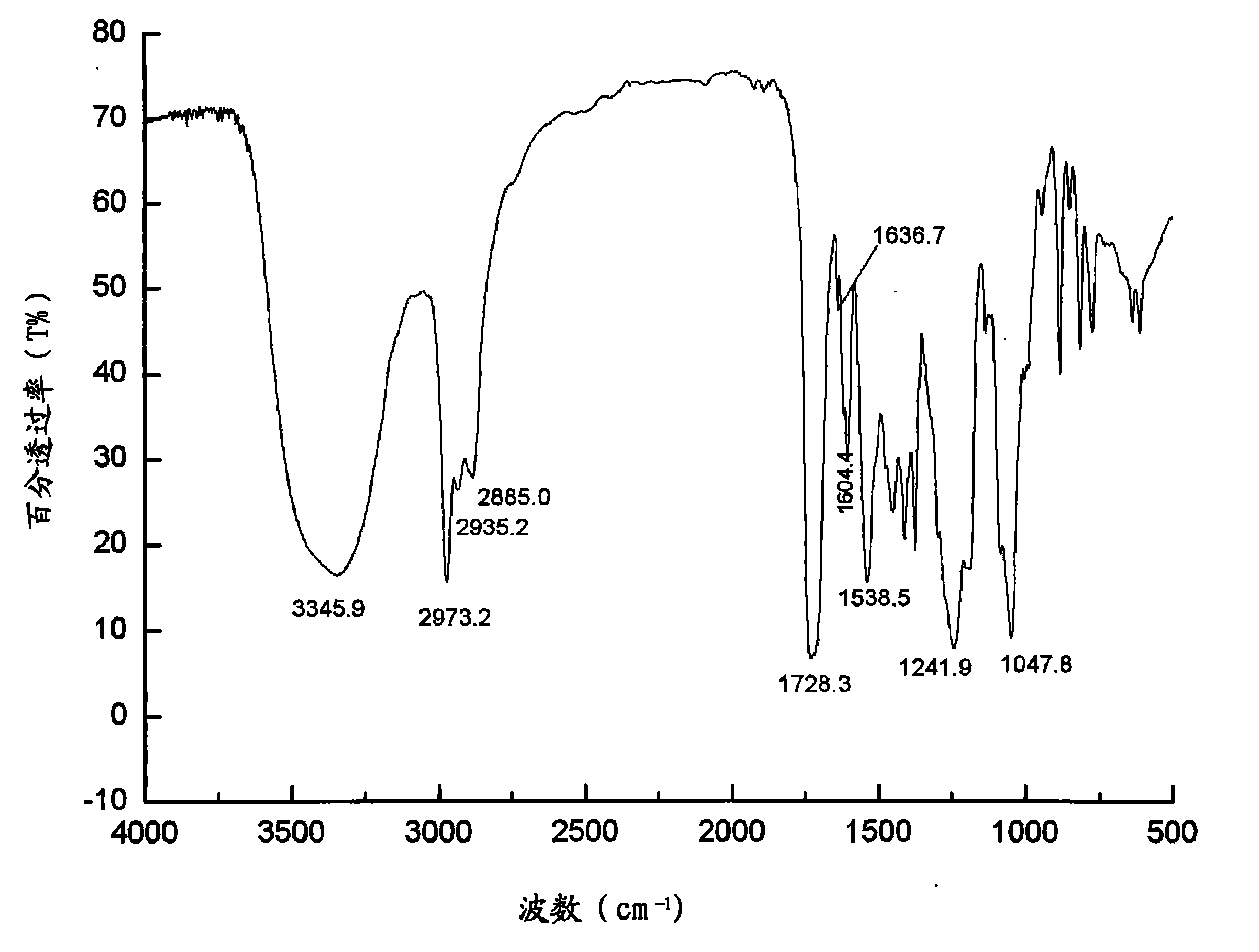

[0084] Get appropriate amount of gained monomer, adopt liquid film method to carry out infrared spectroscopic analysis according to this area routine technical means (test result sees figure 1 ).

[0085] (2) In a reaction kettle equipped with a stirring device, a reflux ...

Embodiment 3

[0101] Embodiment 3: prepare the example of wood varnish of the present invention

[0102] The raw material ratio is as follows:

[0103]45 kilograms of resin solution (solid content 50wt%) prepared by embodiment 1

[0104] 20 kg of nitrocellulose solution (30wt%)

[0105] Dibutyl ester 3 kg

[0106] Ethyl acetate 12 kg

[0107] Butanol 8 kg

[0108] 12 kg absolute ethanol

[0109] The specific production steps include:

[0110] Put the above-mentioned raw materials into a container, stir for 10 minutes, let them fully mix and disperse evenly, and then filter and serve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid containing ratio | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com