Broken soil vibration and compaction treatment method by utilizing impact hammer in immersed tube in riprap filled foundation

A foundation treatment and impact hammer technology, which is applied in soil protection, foundation structure engineering, sheet pile walls, etc., can solve the problems of inability to pass through piles, uneven particle arrangement and skeleton of the filling layer, thickness of the filling layer and buried depth and other problems. problems such as uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

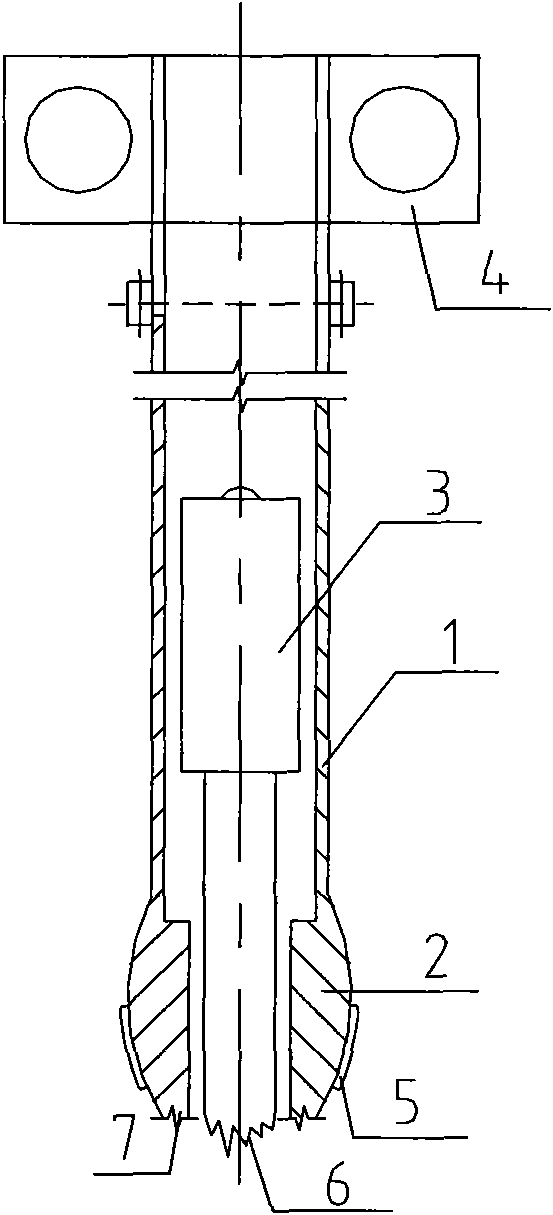

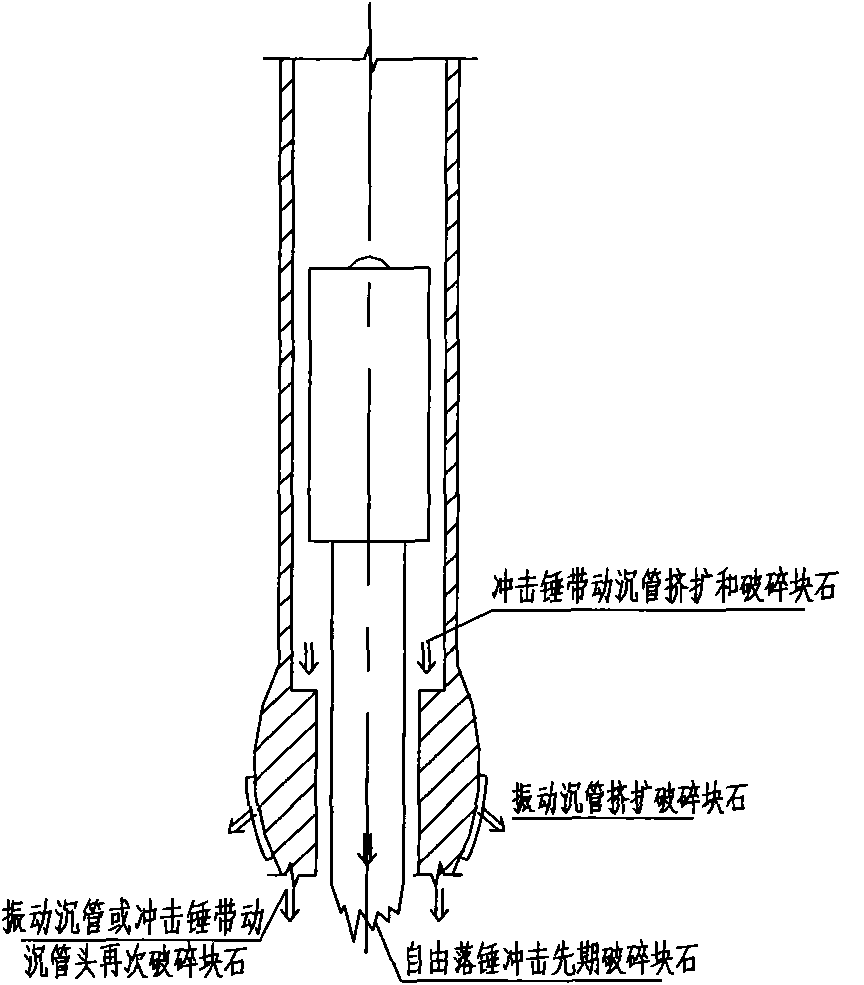

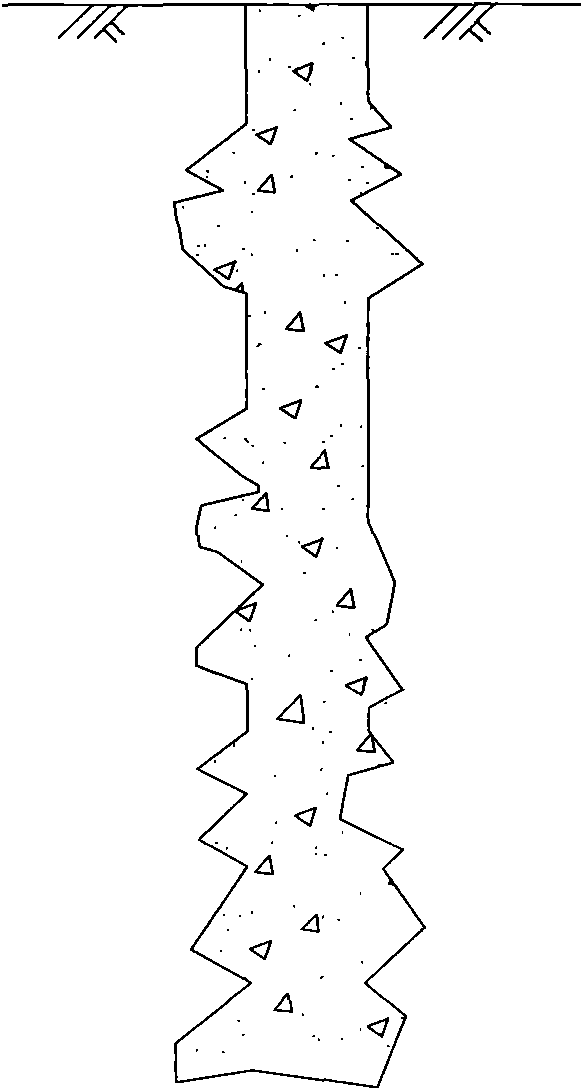

[0020] 1. According to the grid-like plane layout of the pile positions, the extrusion and compaction effect of the internal hammer impacting the vibrating immersed tube is used to make the stacked structure of random piles of rocks dislocated and compacted. Among them, the impact of the hammer inside the pipe can break the large stones to make the pipe sink and compact the foundation, and the vibration and impact of the immersed pipe driven by the vibrating hammer can perform the secondary crushing, expansion and compaction of the stones. In combination, shallow and deep compaction can be performed on such filling layers;

[0021] 2. At the same time as the above "1" immersed tube is compacting, put gravel, sand or slag into the immersed tube, use the hammer in the tube to compact the filling layer, and form gravel after vibrating and pulling out the tube Flexible pile composite foundations such as piles, sand piles or slag piles;

[0022] 3. At the same time as the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com