Cleaning method of underground anchor rod during underground diaphragm walls construction

An underground diaphragm wall and cleaning method technology, applied in the field of multi-layer bolt cleaning, can solve the problems of affecting construction progress, increasing construction investment, and large soil disturbance of the underground diaphragm wall groove wall, etc. The construction progress is slow and the effect of good wall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

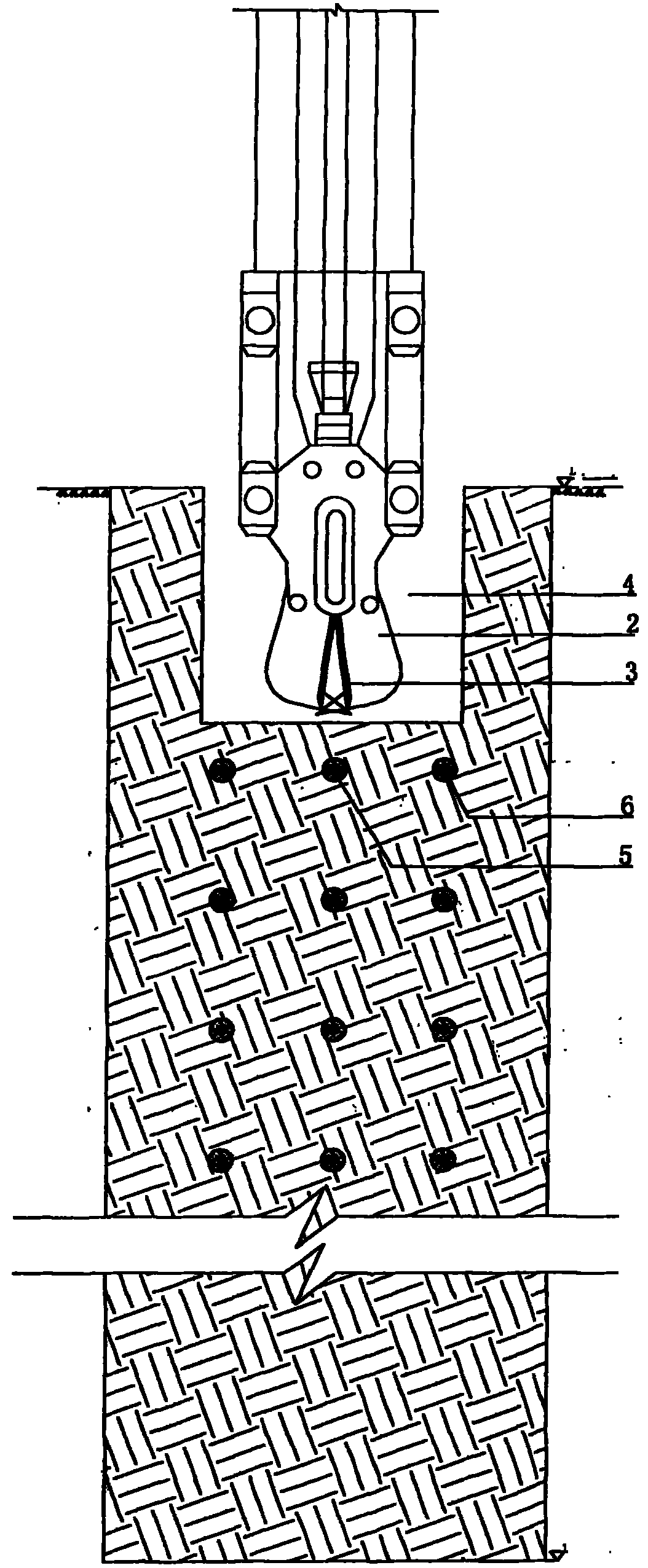

[0028] Below with reference to accompanying drawing, describe the specific implementation steps of the present invention:

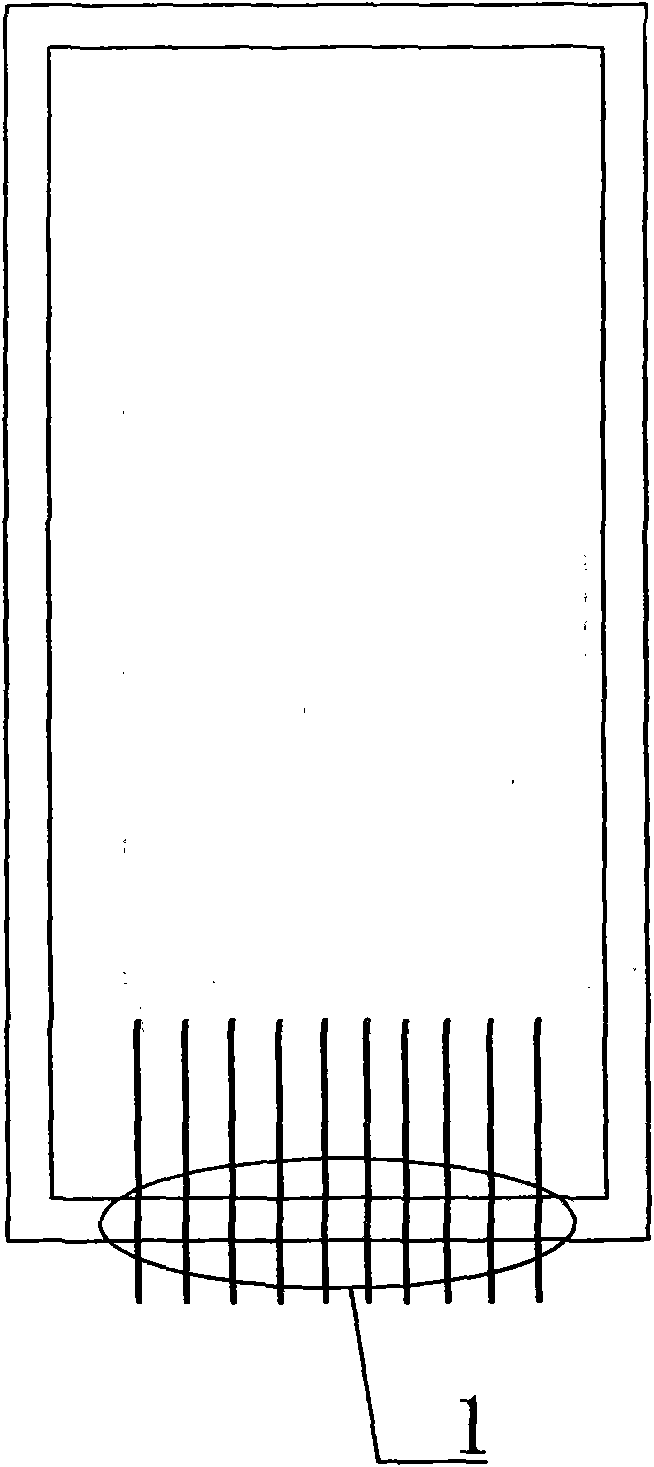

[0029] 1) Organize and analyze the original construction data of the underground anchor bolts within the scope of the construction site, and delineate the construction scope of the underground diaphragm wall trenching (see 1 figure 1 ).

[0030] 2) Through the trial production of underground anchor rod samples, conduct hydraulic shear tests at the groove forming machine manufacturer, analyze various possible conditions, and determine the shear parameters.

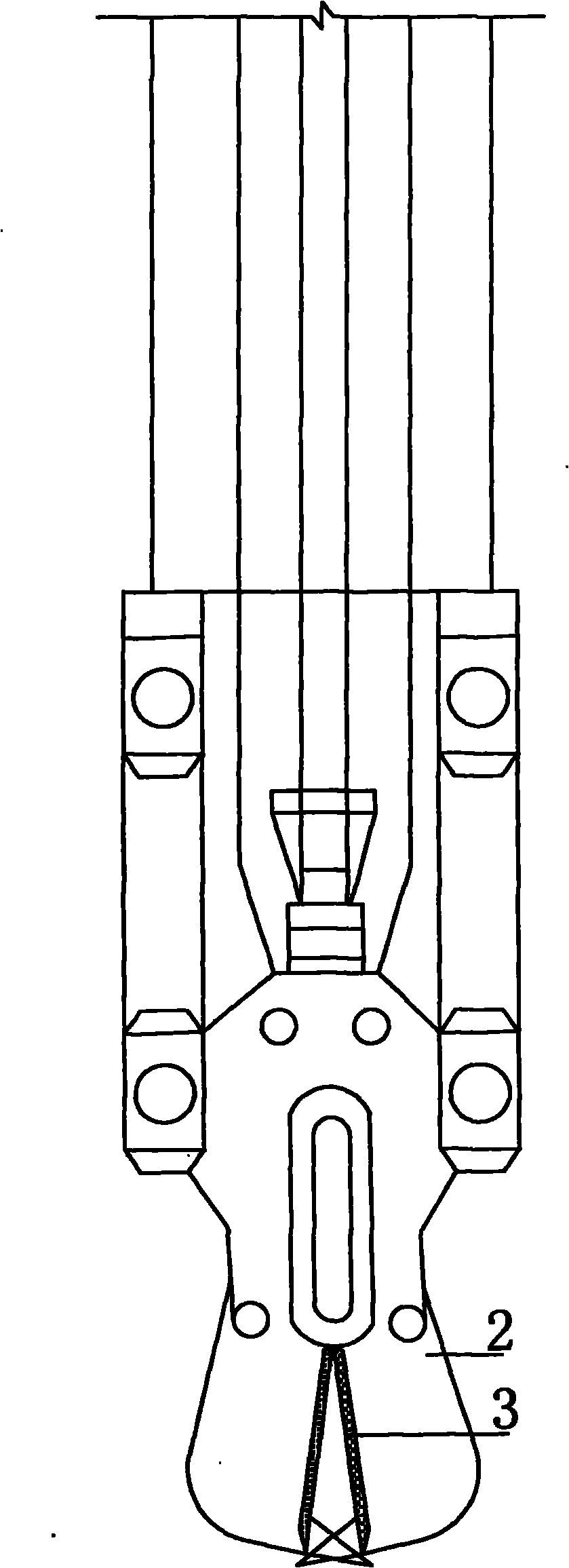

[0031] 3) Weld tungsten steel sheets 3 with good toughness and wear resistance on both sides of the hydraulic grab side plate 2 of the hydraulic grooving machine (see figure 2 ), transported to the site, reinstalled on the site and can carry out trial shearing on the hydraulic grooving machine that needs to be carried out.

[0032] 4) After the trial shearing is passed, determine the reasonable shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com