Plate grooving machine

A grooving machine and plate technology, which is applied to stone processing tools, wood processing appliances, stone processing equipment, etc., can solve the problems of limited contact, incapable of narrowing plate grooving, saw blade jacking up or reverse pushing, etc. The effect of effective compression and transmission, simple structure and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

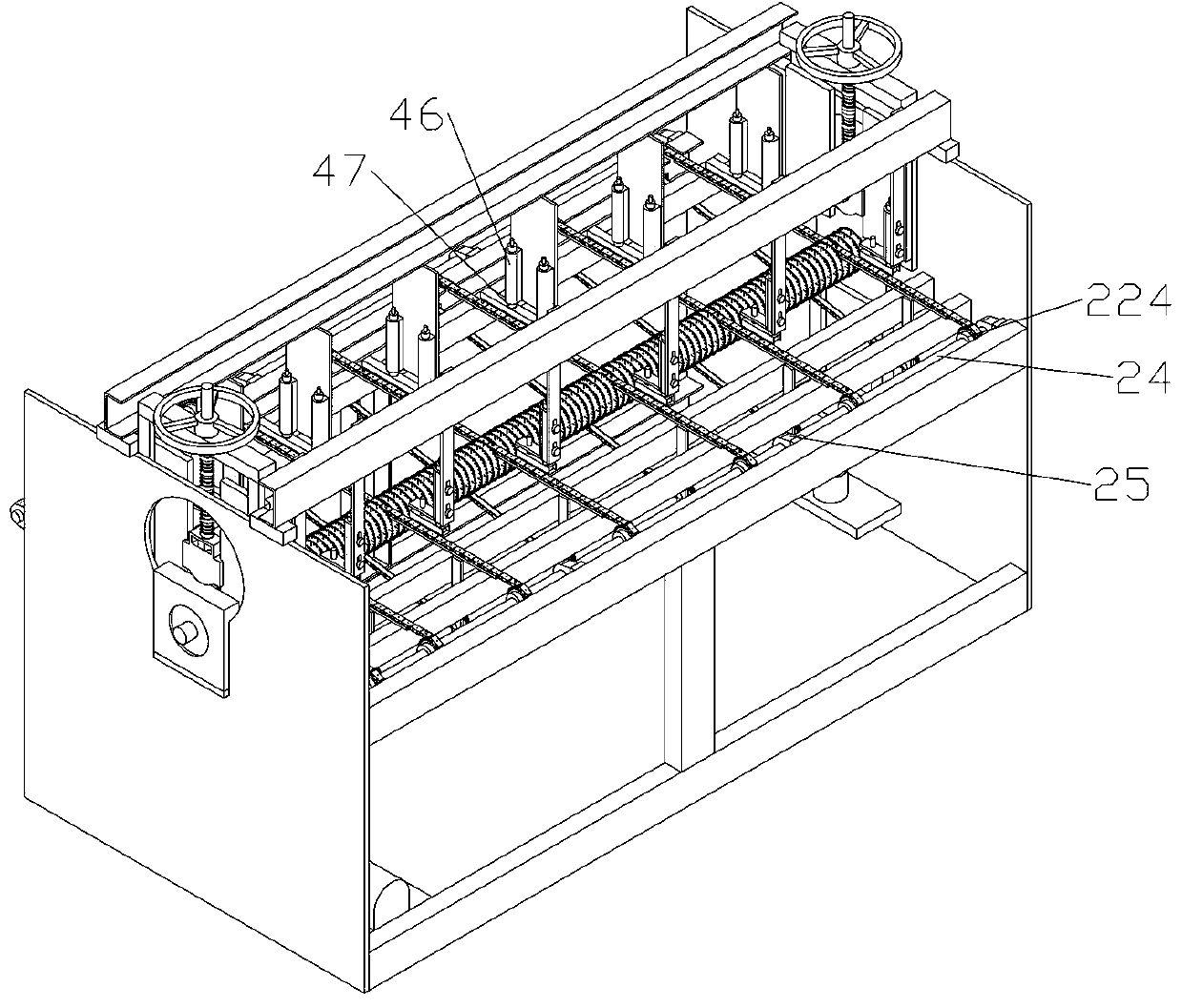

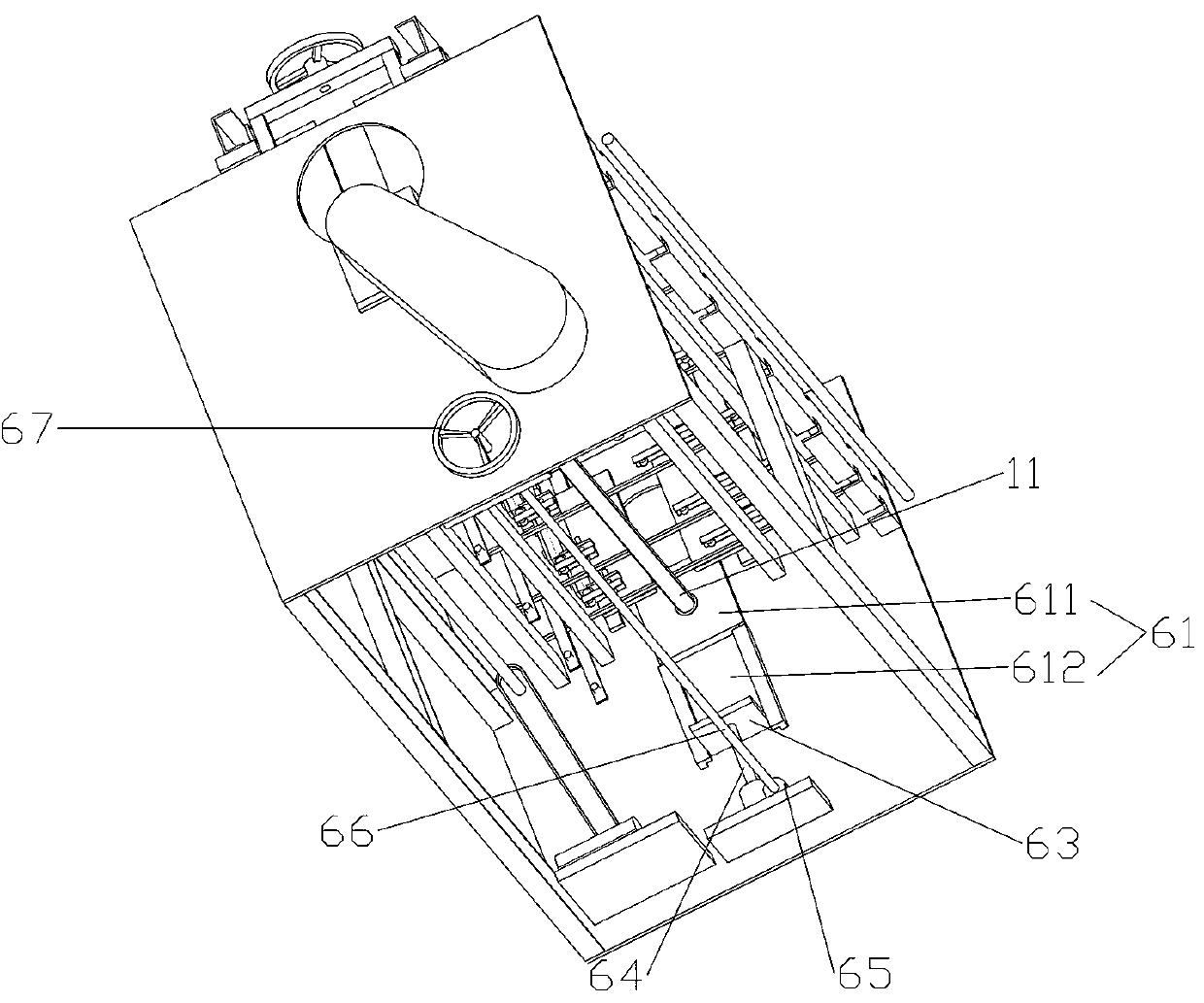

[0043] A board slotting machine, comprising a frame, a board slotting saw structure and a board conveying structure arranged on the frame; sheet 12 and a shaft drive motor for driving the long saw shaft to rotate; the plate conveying structure includes multiple sets of conveying chain assemblies, an auxiliary platen assembly opposite to the conveying chain assembly, and a sprocket for driving the conveying chain to rotate Drive the motor, a plate passage 21 is provided between the auxiliary platen assembly and the conveying chain assembly, the auxiliary platen assembly is located above the conveying chain assembly, and the conveying chain assembly at least corresponds to the area of the plate passage The underlayment is provided with inner stays 22 for ensuring the rigid support of the conveyor chain; the frame includes end frame parts 31 positioned at both ends of the long saw shaft and a carriage part 32 connected between the end frame parts. The two ends of the shaft are ...

Embodiment 2

[0047] The difference from the above embodiment is that the bottom of the inner stay is also connected with a lower stay 221, and the bottom of the lower stay is connected with a tensioning sprocket 222 through a slotted hole along the height direction. It is wound on the tension wheel and adjusts the tension of the conveyor chain by adjusting the tension wheel up and down.

[0048] The conveyor chain has no rigidity as a whole, and the inner stays are required to support the part that needs to be supported by steel to ensure the rigidity and horizontal transmission of the plate. The conveyor chain will not hit the front and rear ends of the inner stays to cause failure. The setting of the tensioning sprocket is convenient for disassembly and maintenance of the conveyor chain.

[0049] The chain link cover includes a support surface and side cover surfaces located on both sides of the support surface for respectively connecting with two sides of the chain link, and there is a...

Embodiment 3

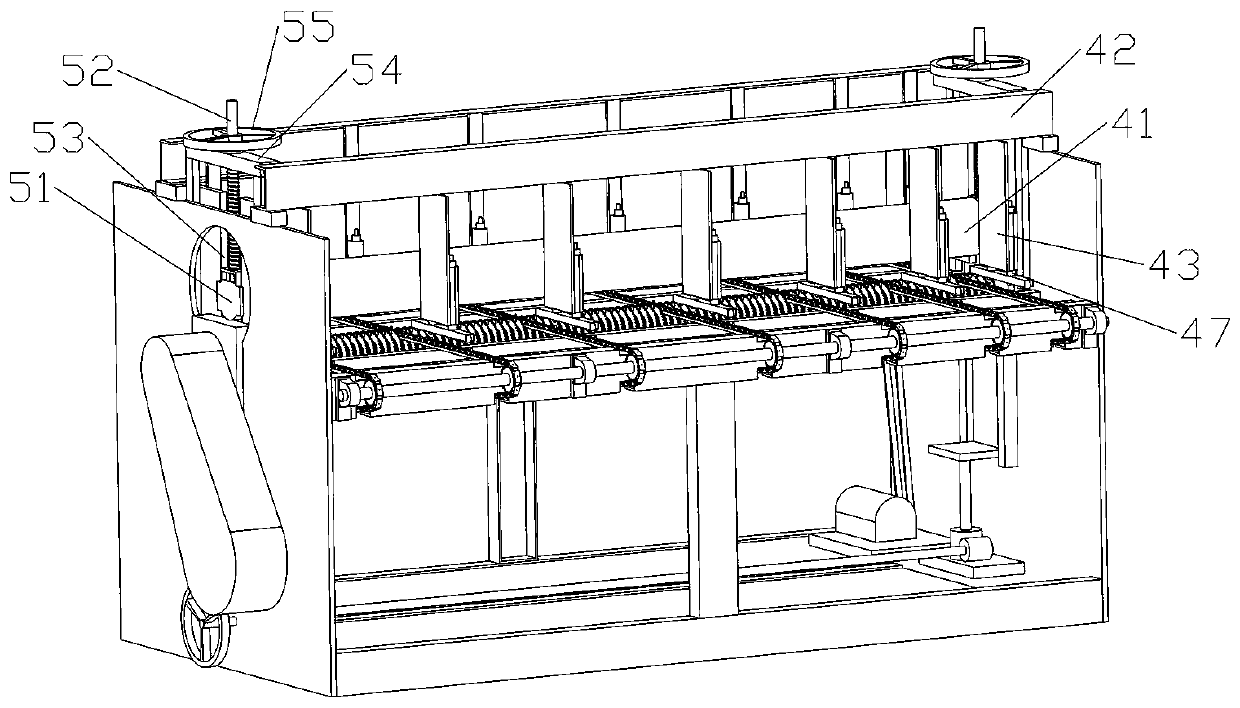

[0051] The difference from the above embodiments is that the auxiliary platen assembly includes a main pressure roller 41 arranged above the long saw shaft and auxiliary import and export components arranged on the front side and / or rear side of the main pressure roller. The import and export parts include a main girder 42 erected on the end frame part, a plurality of suspenders 43 suspended on the main girder and corresponding to the conveying chain one by one, and the bottom of the suspender along the The auxiliary wheel mounting seat 44 provided in the length direction of the conveying chain and the auxiliary wheel 45 arranged on the auxiliary wheel mounting seat; The matching connection of the adjustment rod 46 can adjustably connect the suspension rod up and down. The auxiliary wheel adjustment rod is a hollow tube with a pressure spring inside. The auxiliary wheel mounting seat passes through the hollow tube The suspension shaft 47 is connected to the auxiliary wheel adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com