Small-sized drill pile-up valve

A technology of integrating valves and drilling rigs, applied in mechanical equipment, fluid pressure actuating devices, servo motor components, etc., can solve the problems of poor sealing design at the spool valve, increased possibility of external leakage, and reduced system reliability, etc. To achieve the effect of convenient maintenance, reduced opening and closing frequency, and improved surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

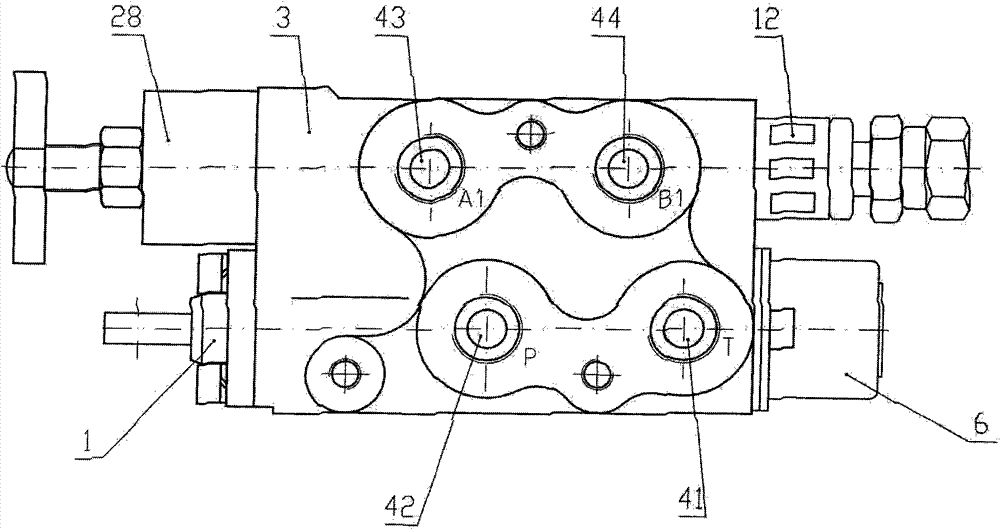

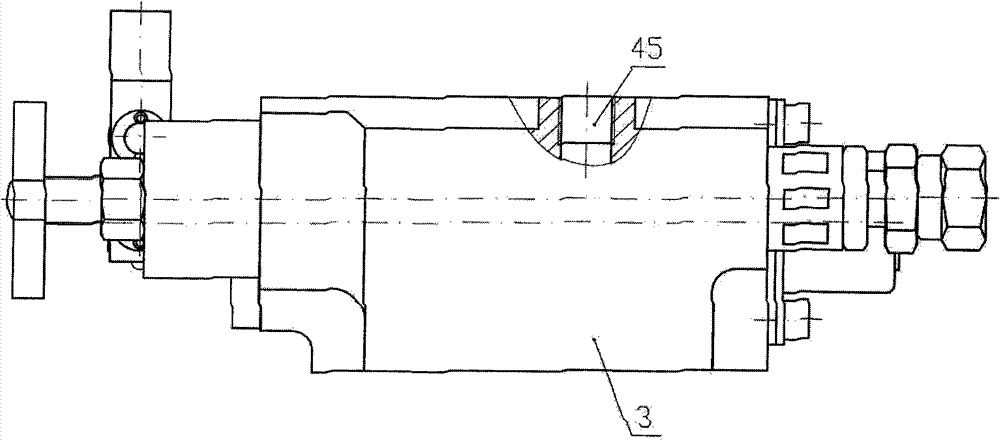

[0028] see figure 1 , figure 2 and image 3 The integrated valve for a small drilling rig shown includes a reversing valve, an overload valve, and a balanced one-way throttle valve in the valve body 3. The cavity of the overload valve and the valve cavity of the balanced one-way throttle valve are respectively cast The flow passage communicates with the reversing valve cavity; the valve body 3 is provided with a first oil port 41, a second oil port 42, a third oil port 43, a fourth oil port 44 and a pressure gauge interface 45;

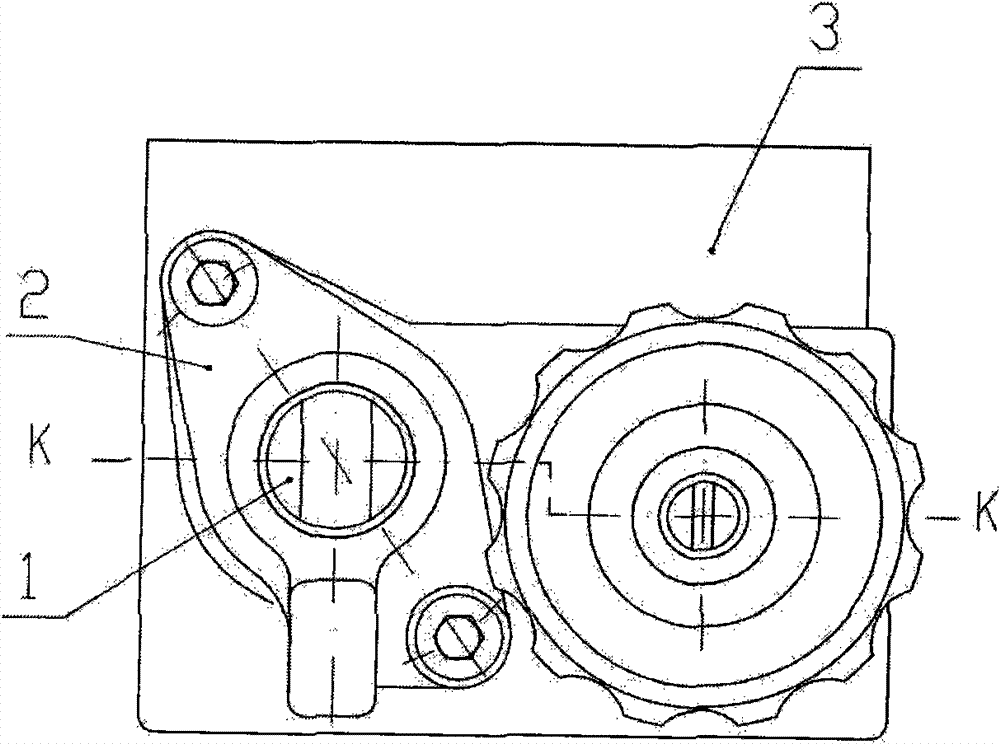

[0029] see Figure 4 , Figure 5 and Figure 6 , the reversing valve includes a spool valve 1 matched with the valve cavity of the spool valve, a bracket 2 matched with the left end of the spool valve and closely attached to the valve body 3, a bracket 2 matched with the right end of the spool valve and closely attached to the valve body 3 The baffle plate 4, the first spring seat 5 set on the right end of the slide valve, one end is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com