Optical cable secondary-coating bulge detecting device

A technology of secondary plastic wrapping and detection device, which is applied in the direction of measuring device, mechanical measuring device, and mechanical device, etc., can solve the problems of high price, rupture of bundled tubes, loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

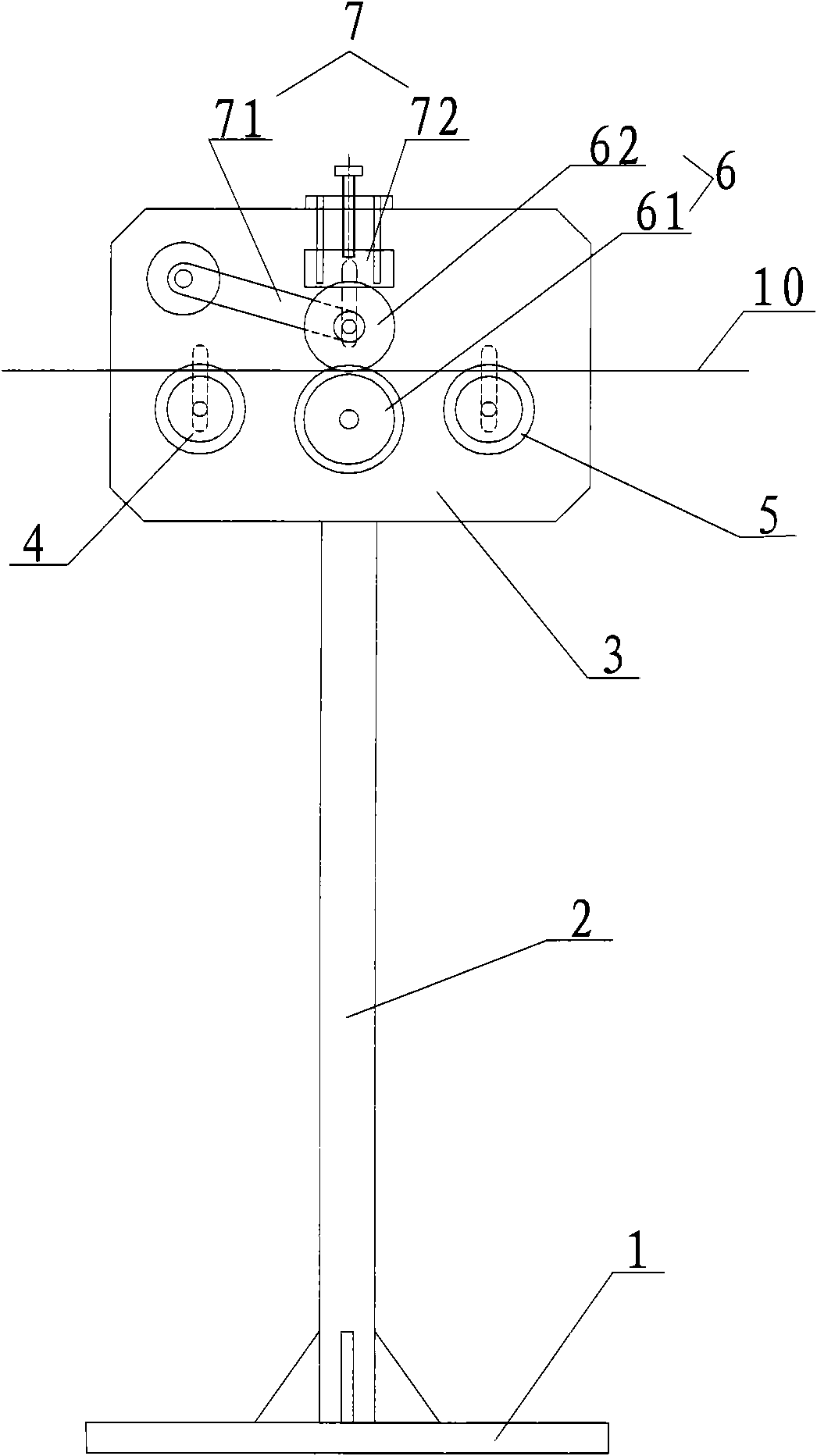

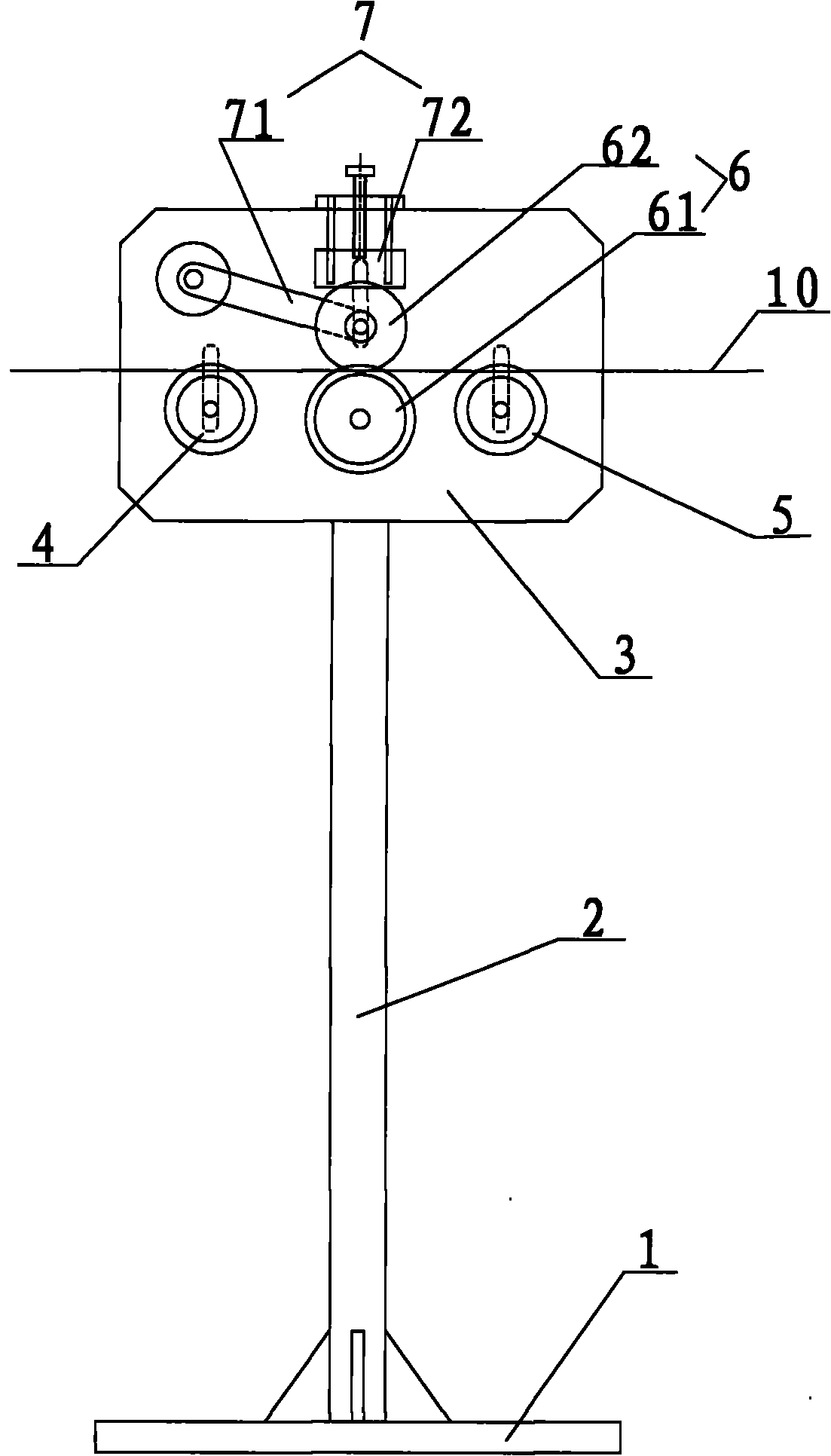

[0012] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0013] like figure 1 The secondary plastic bulge detection device shown includes a base plate 1 fixed on the ground, a connecting pipe 2 vertically fixed on the base plate 1, a guide wheel fixing plate 3 installed on the connecting tube 2, and a guide wheel fixing plate 3 is equipped with incoming line guide wheel 4, outgoing line guide wheel 5, movable guide wheel 6 and detection mechanism 7, wherein, movable guide wheel 6 is made up of the support wheel 61 that is positioned between incoming line guide wheel 4 and outgoing line guide wheel 5 and is positioned at The supporting wheel 61 top is made up of movable wheels 62 meshed with it, the axis lines of each guide wheel are parallel, and the axis lines of the incoming line guide wheel 4 and the outgoing line guide wheel 5 are on the same horizontal plane, that is, the two are arranged side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com