Fiber grating clamp-type helical line slow-wave structure

A fiber grating and slow-wave structure technology, which is applied in the field of microwave electronics, can solve problems such as the inability to obtain temperature distribution, and achieve the effect of suppressing back-wave oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

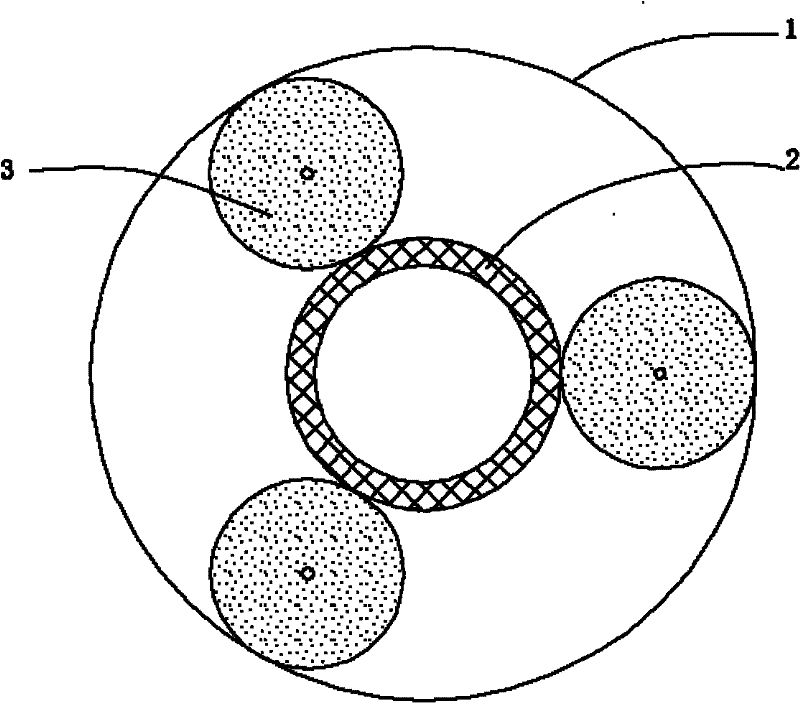

[0023] The fiber Bragg grating clamping type helical slow wave structure of the present invention uses Bragg fiber grating as the clamping rod material, that is, a helix 2 is arranged on the axis of the shell 1, and a fiber grating 3 is arranged between the shell and the helix .

[0024] Fiber Bragg Gratings are circular clamping rods.

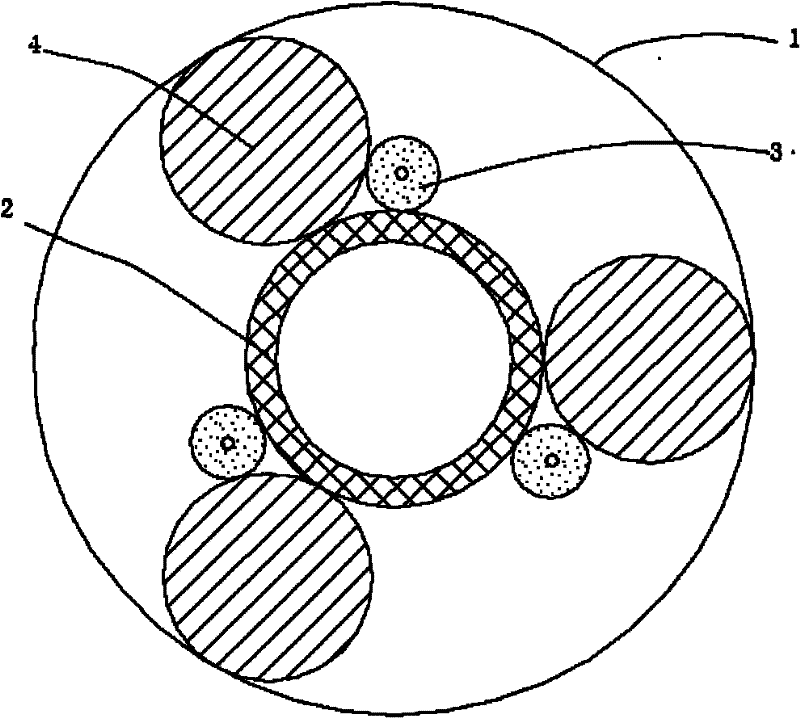

[0025] A carbon film is plated on the fiber grating to make a distributed attenuator to suppress the return wave oscillation of the traveling wave tube.

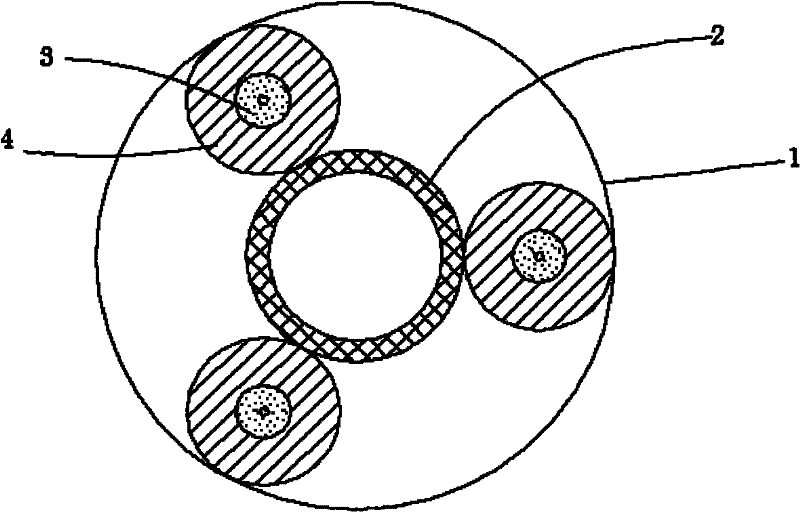

[0026] A circular clamping rod or a fan-shaped clamping rod with a distributed attenuator is arranged outside the fiber grating cladding.

[0027] Place the fiber grating next to the circular clamping rod or fan-shaped clamping rod, and fix it with glue.

[0028] In order to realize the distributed measurement of the temperature of the helix, the structure uses Bragg fiber grating as the clamping rod material, that is, the helix 2 is arranged on the axis of the shell 1, and the optical fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com