Rhombic meander line slow wave structure loaded on basis of multiple dielectric rod supporting ridges

A technology of slow wave structure and dielectric rod, which is applied in the cooling method of discharge tube, transit time type electronic tube, electrical components, etc., can solve the problems of heavy workload and cumbersome strip line process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

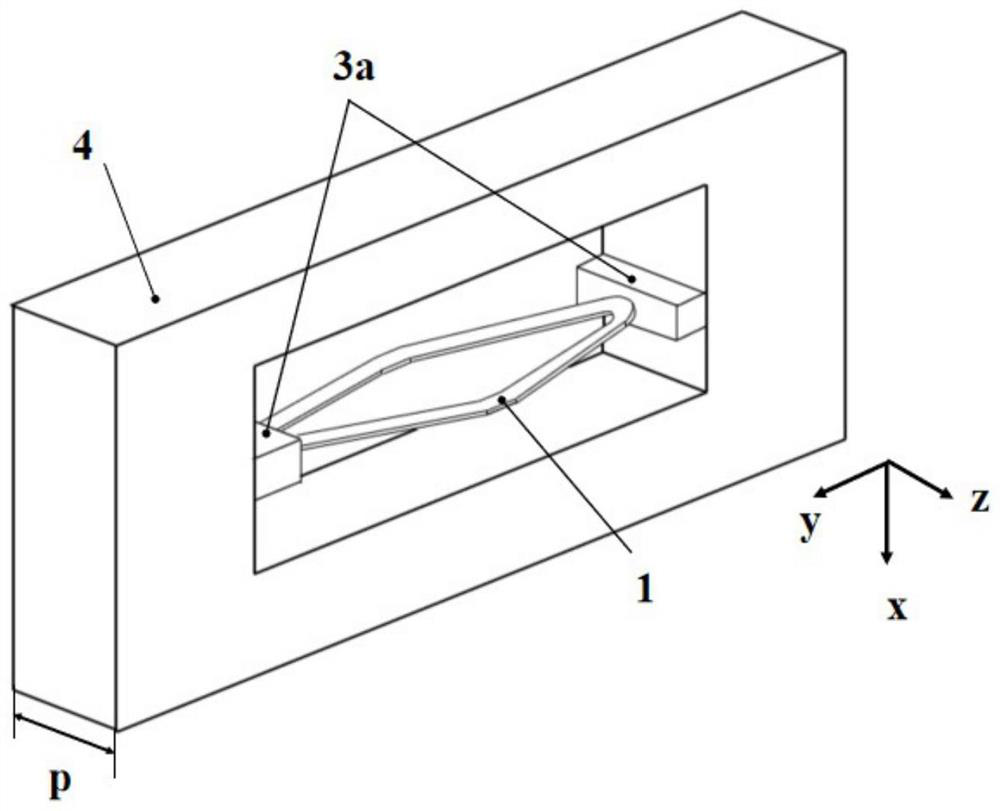

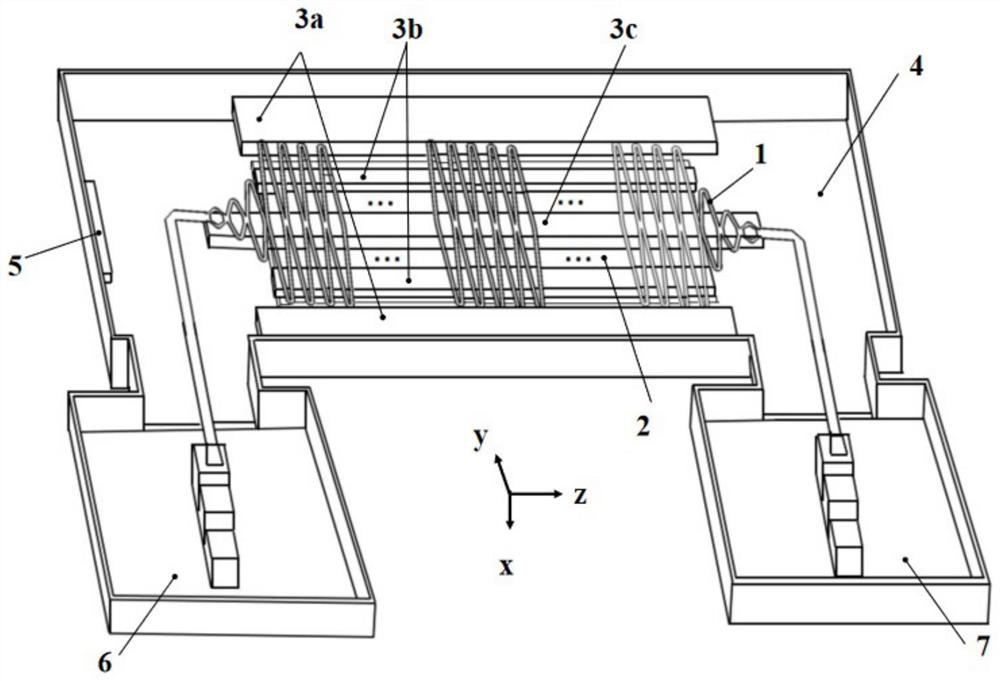

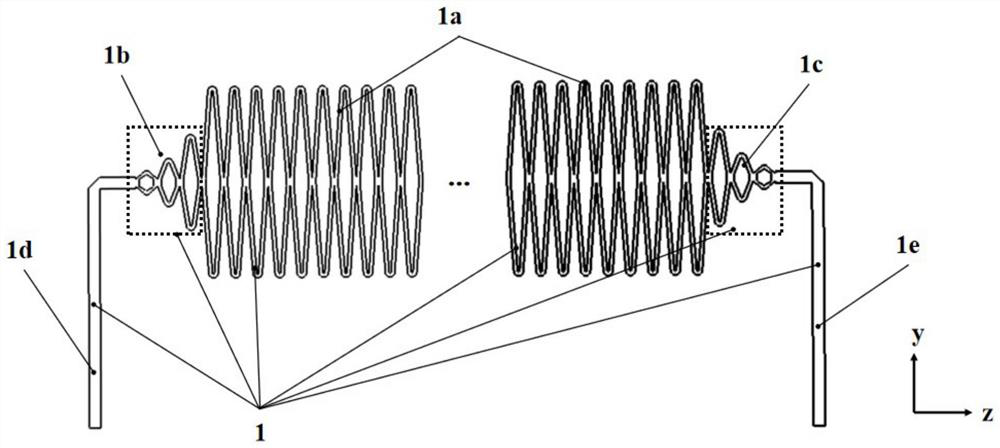

[0037] figure 2 It is a structural schematic diagram of a specific embodiment of the present invention based on a plurality of dielectric rod support ridges loading a rhombic zigzag line slow wave structure.

[0038] In this example, if figure 2 As shown, the present invention is based on a plurality of dielectric rod support ridges loading rhombic zigzag line slow wave structure, including a metal slow wave line 1, multiple metal ridges 2, clamping rods 3a on both sides, and multiple (three) bottom side clamping rods. Rods 3b, 3c, metal casing 4, sheet cathode 5, micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com