An angular asymmetric helical slow-wave structure and a manufacturing method of the slow-wave structure

A slow-wave structure and helix technology, applied in the field of vacuum electronic devices, can solve the problems of high-power helical traveling wave tube return wave oscillation, unfavorable heat, large contact thermal resistance, etc., to solve the problems of return wave oscillation and heat dissipation, The effect of improving thermal conductivity and reducing contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

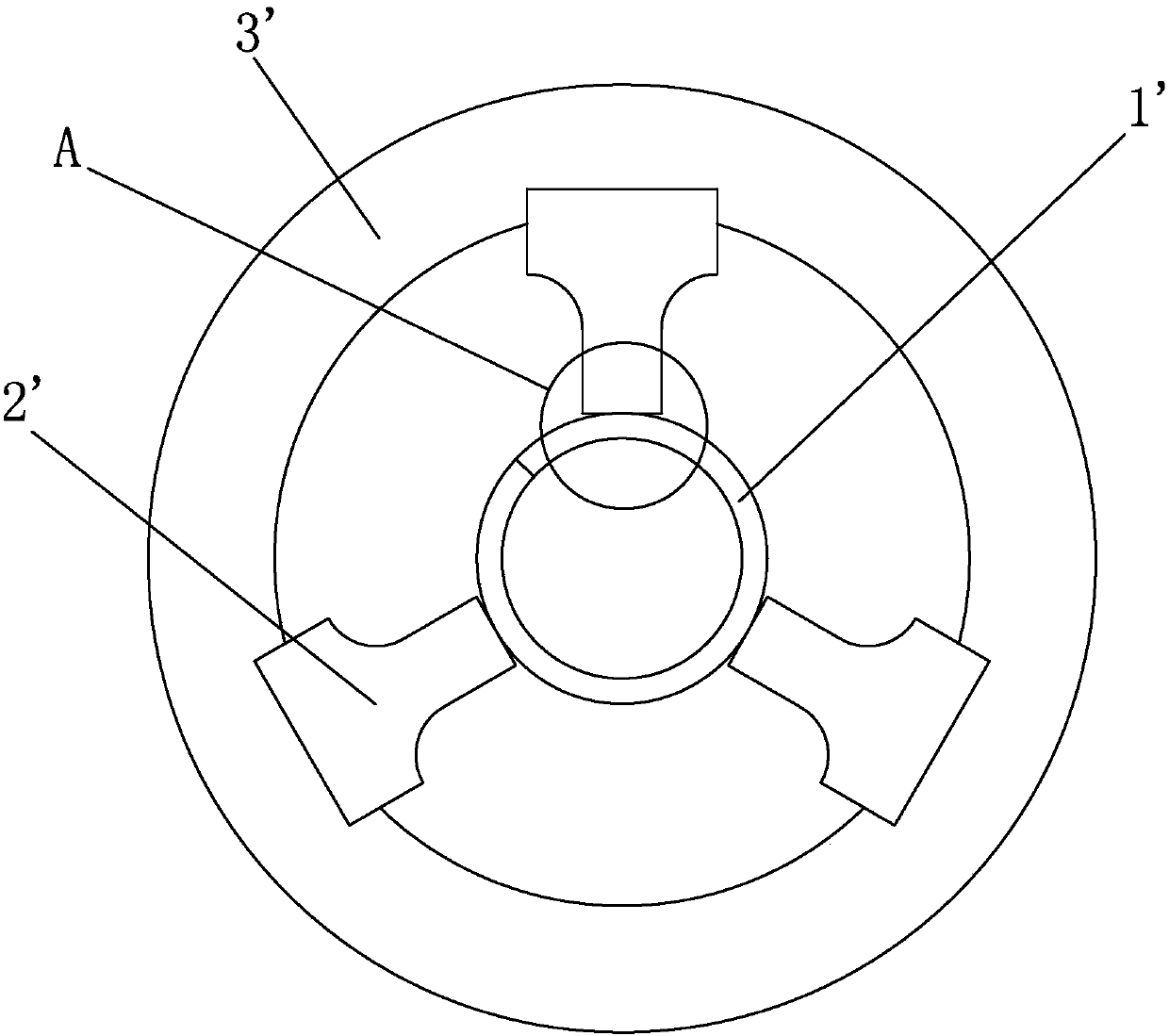

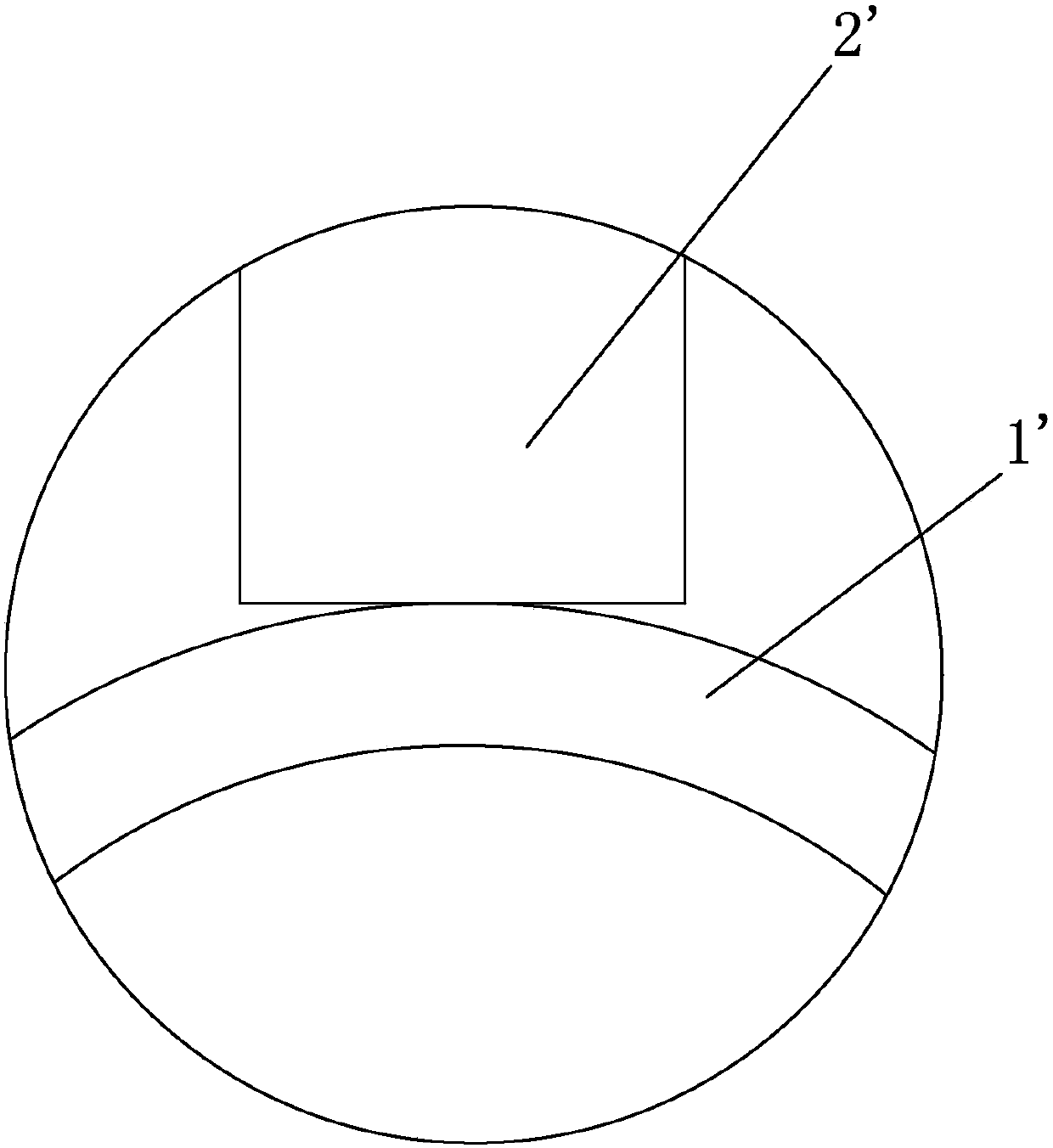

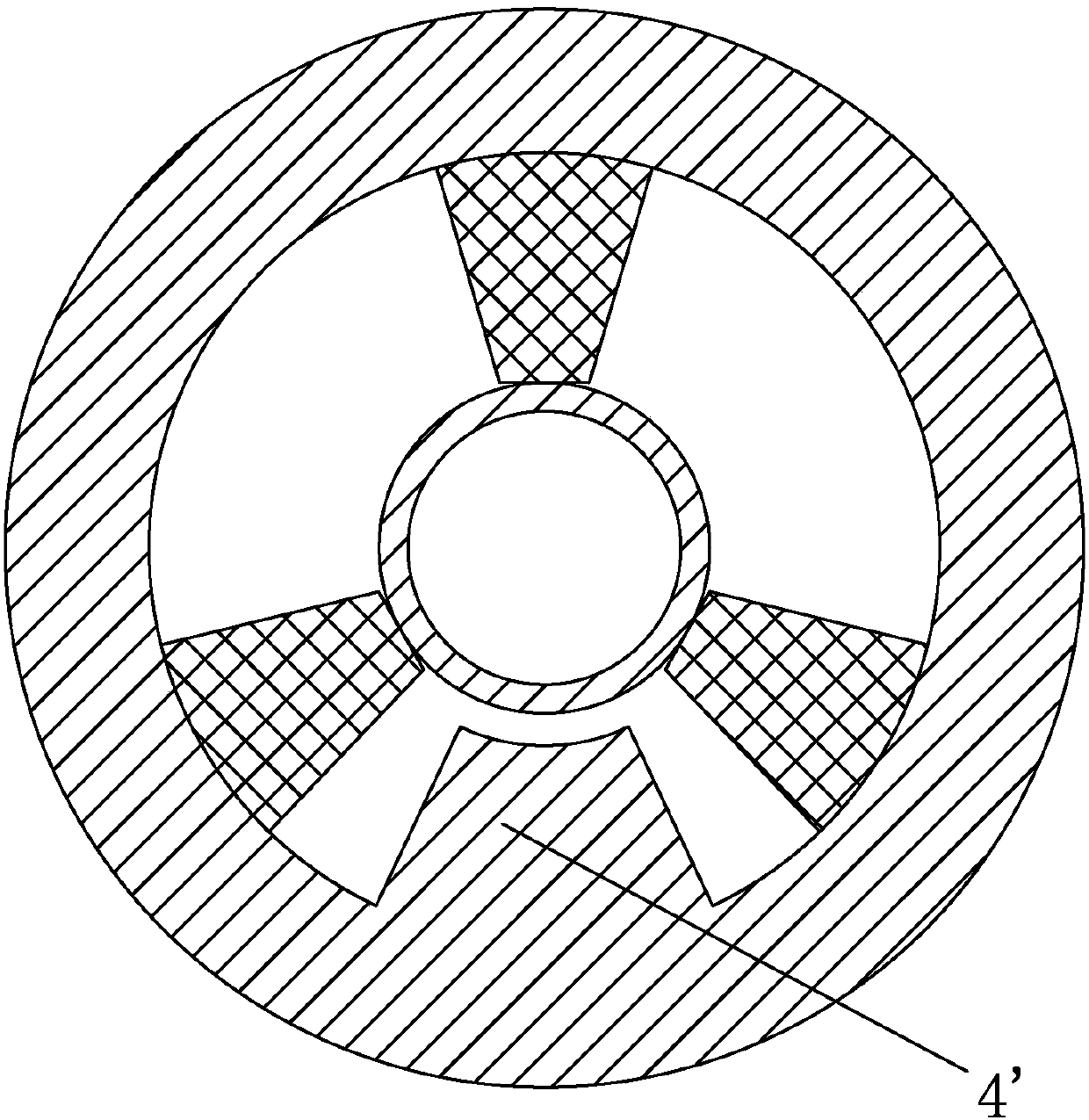

[0050] Such as Figures 4 to 11 As shown, an angular asymmetric helical slow wave structure, the slow wave structure includes a helix 1, a clamping rod 2 and a shell 3, the outer wall of the clamping rod 1 and the inner wall of the shell 3 connection and fixation; a metal loading 4 is arranged between the inner side wall of part of the clamping rod 2 in the clamping rod 2 and the helix 1; The helix 1 is connected and fixed.

[0051] In this embodiment, only a metal loading 4 is provided between a single clamping rod 2 and the helix 1; The first metallized coating layer, the metal loading 4 is connected and fixed to the first metallized coating layer, the metal loading 4 is connected and fixed to the wall surface of the corresponding helix 1 after exposure and photolithography, and the clamping rod The inner side wall of the remaining pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com