Automatic loading system suitable for stacking silicon chips in automatic equipment

An automatic equipment, automatic feeding technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as low efficiency, poor compatibility, complex structure, etc., to improve efficiency, overall reliable operation, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

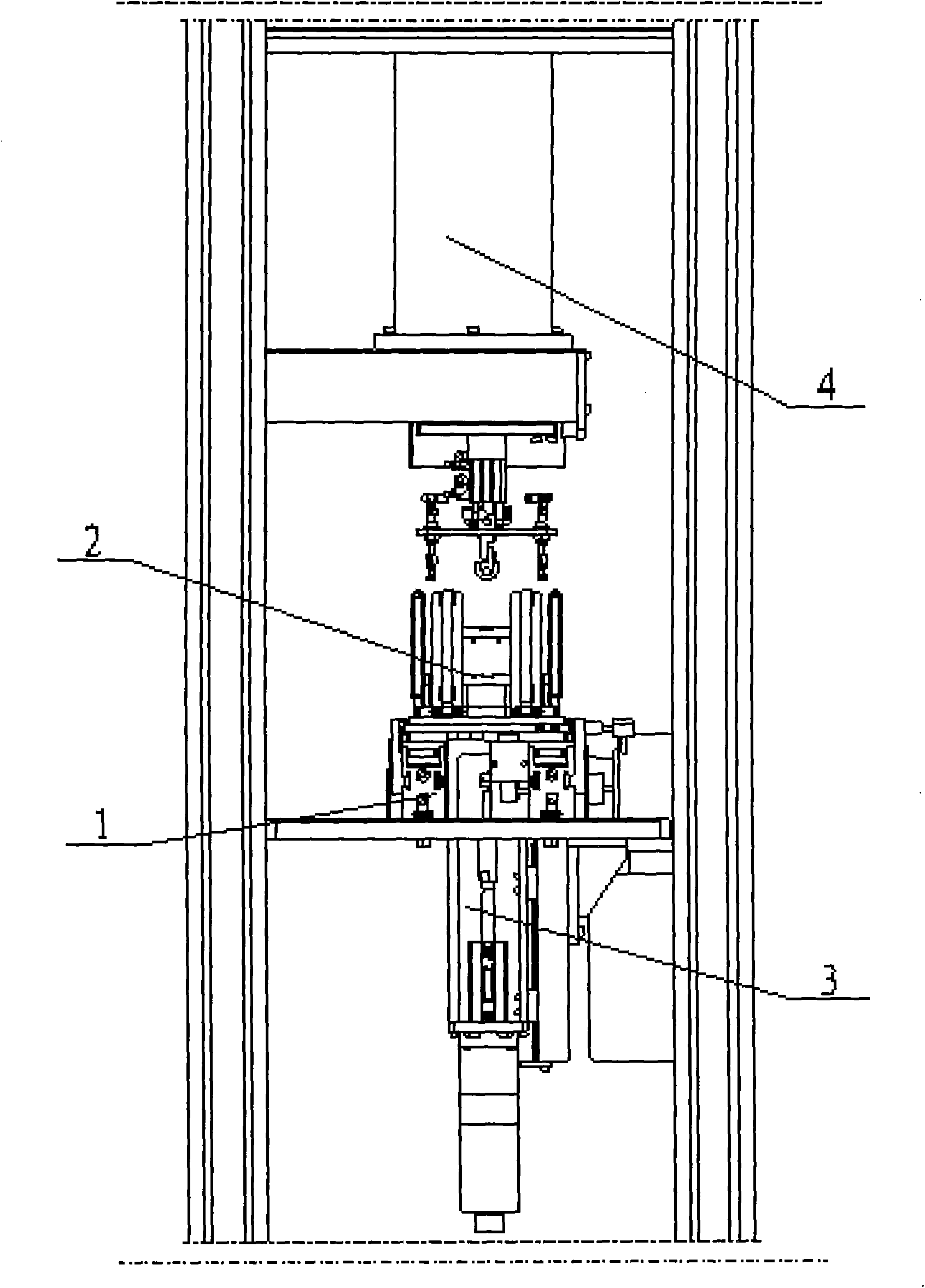

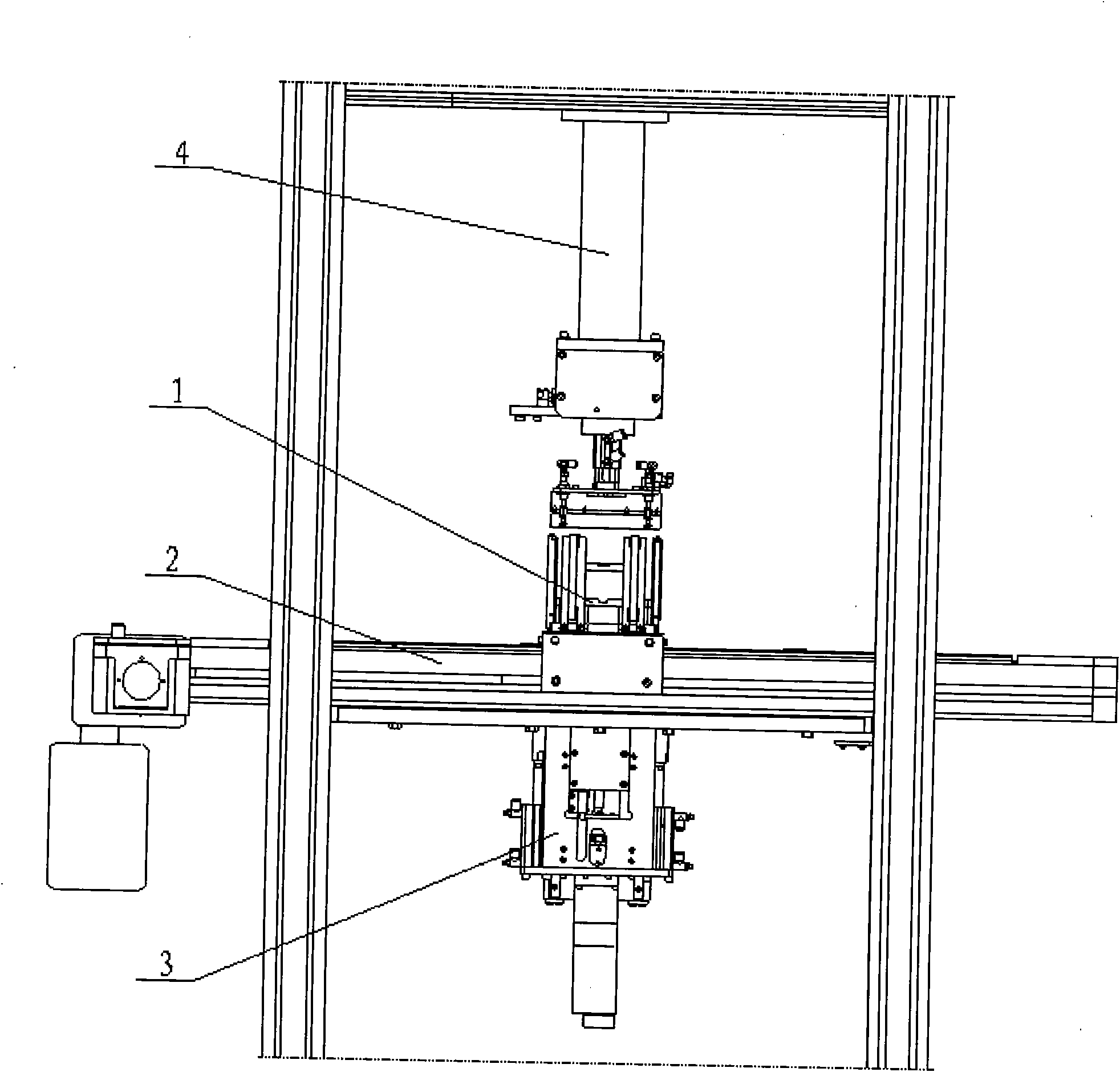

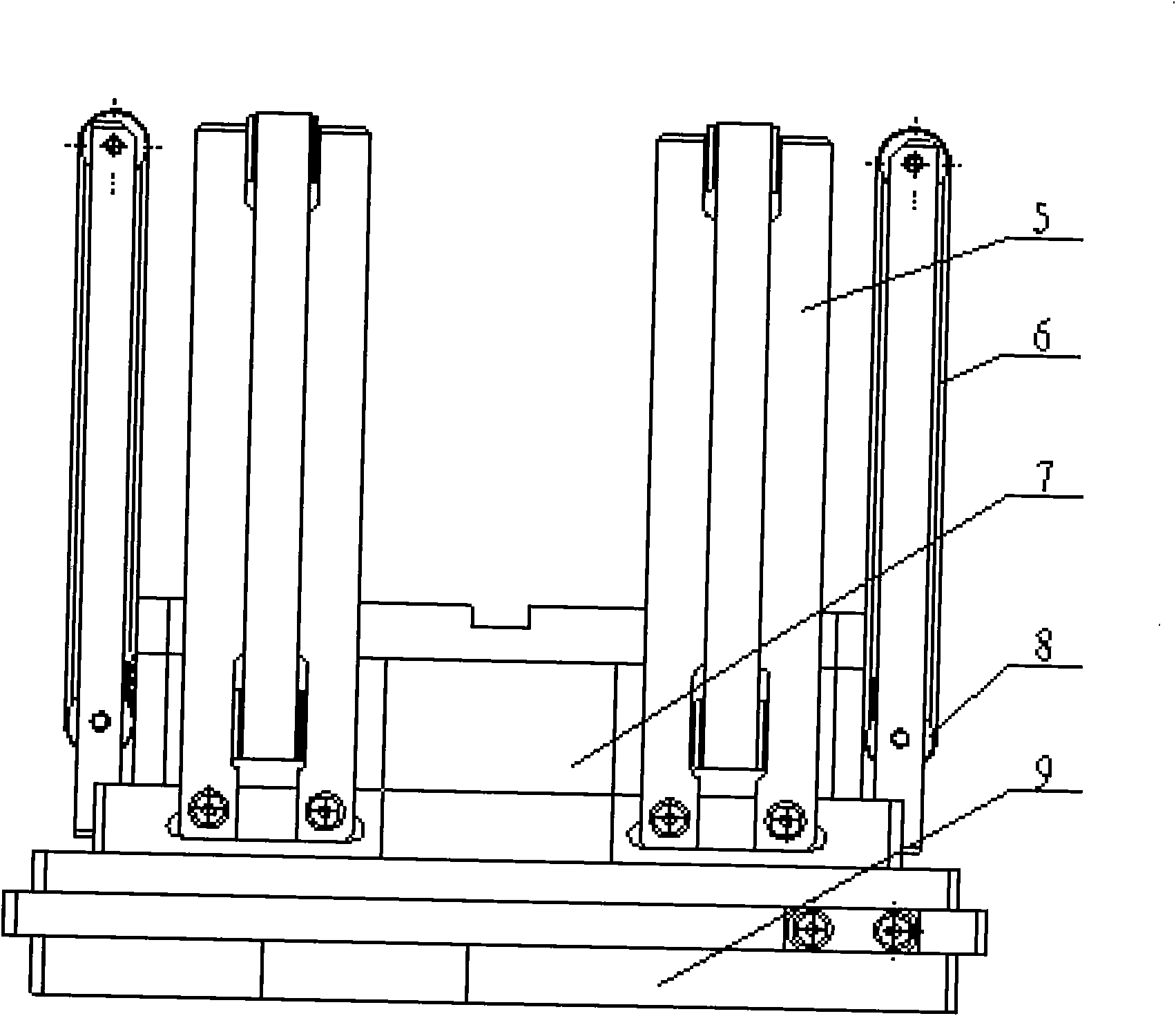

[0018] as attached figure 1 , 2 , 3, 4, 5, and 6 show that the system of the present invention includes a material box 1, an automatic transmission mechanism 2, along which the automatic transmission mechanism 2 is successively provided with a loading pre-station 30, a loading station 31, and a blanking station 32 , equipped with an automatic stop mechanism for blocking and stopping the material box at the pre-loading station, and equipped with an automatic stop mechanism at the loading station, a material box lifting mechanism 3 for positioning the material box and lifting the silicon wafer, And the lateral transfer manipulator 4 that is used to grab the silicon wafer and transfer it to the next process. The stacked material box 1 is transported to the loading station by the automatic transmission mechanism 2, positioned and locked by the material box lifting mechanism 3, driving the silicon wafer to rise, and the horizontal transmission robot 4 grabs and transports the sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com