Photovoltaic power generation solar cell subassembly section bar frame

A solar cell and photovoltaic power generation technology, which is applied in the field of solar energy applications, can solve the problems of poor installation fastness, troublesome installation and disassembly, and high labor intensity of the connection between the roof and battery components, so as to reduce labor intensity, ease operation, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

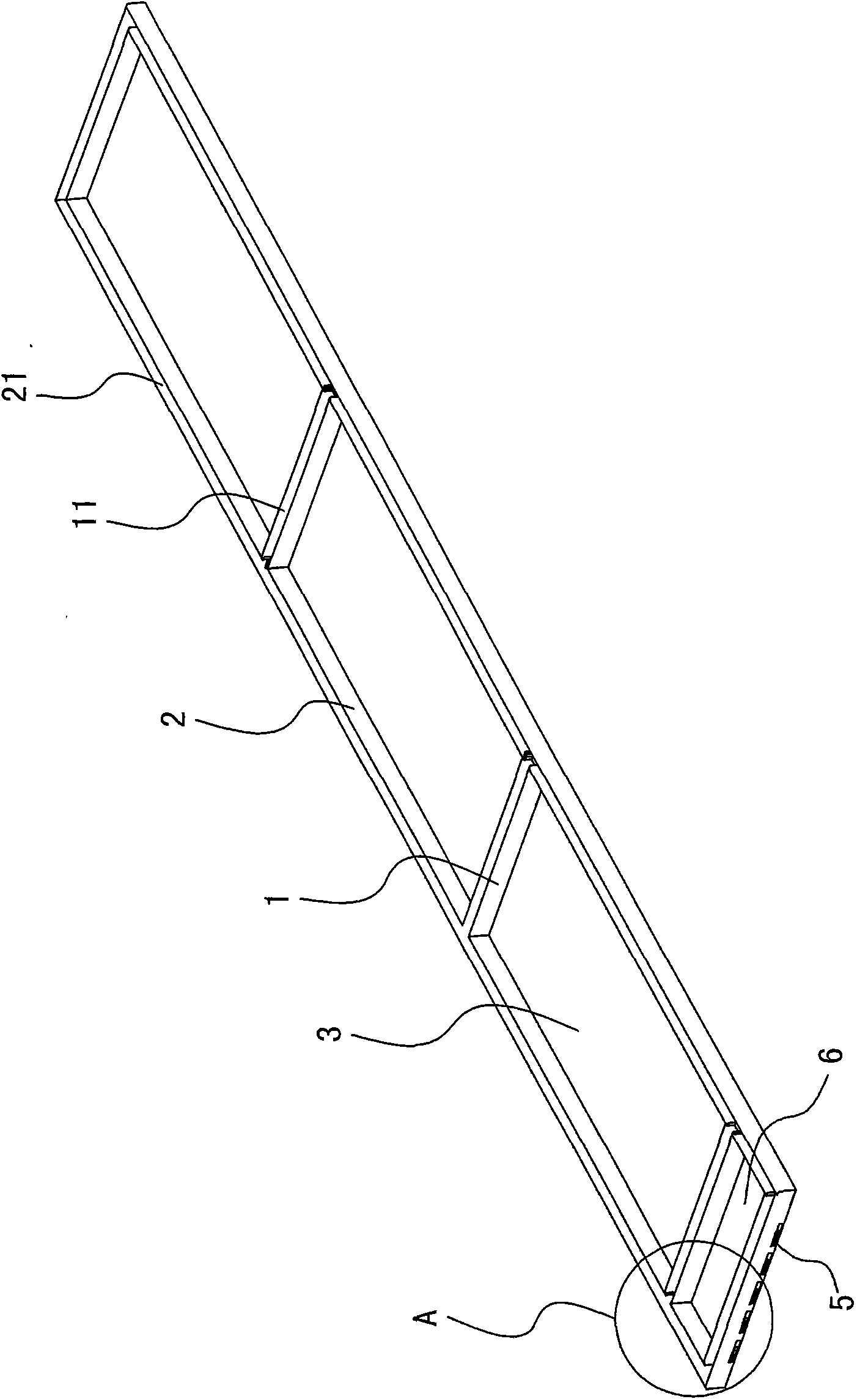

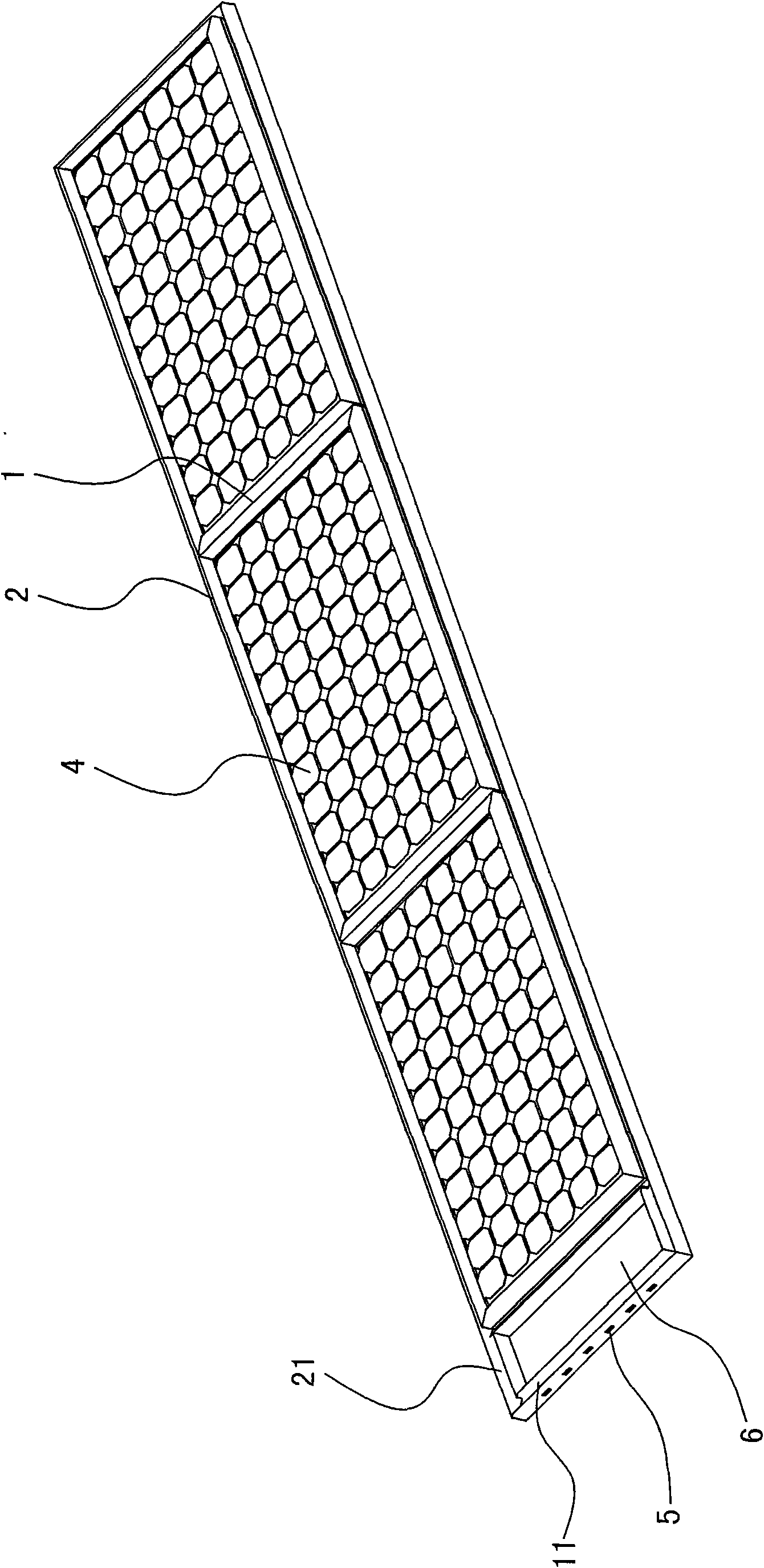

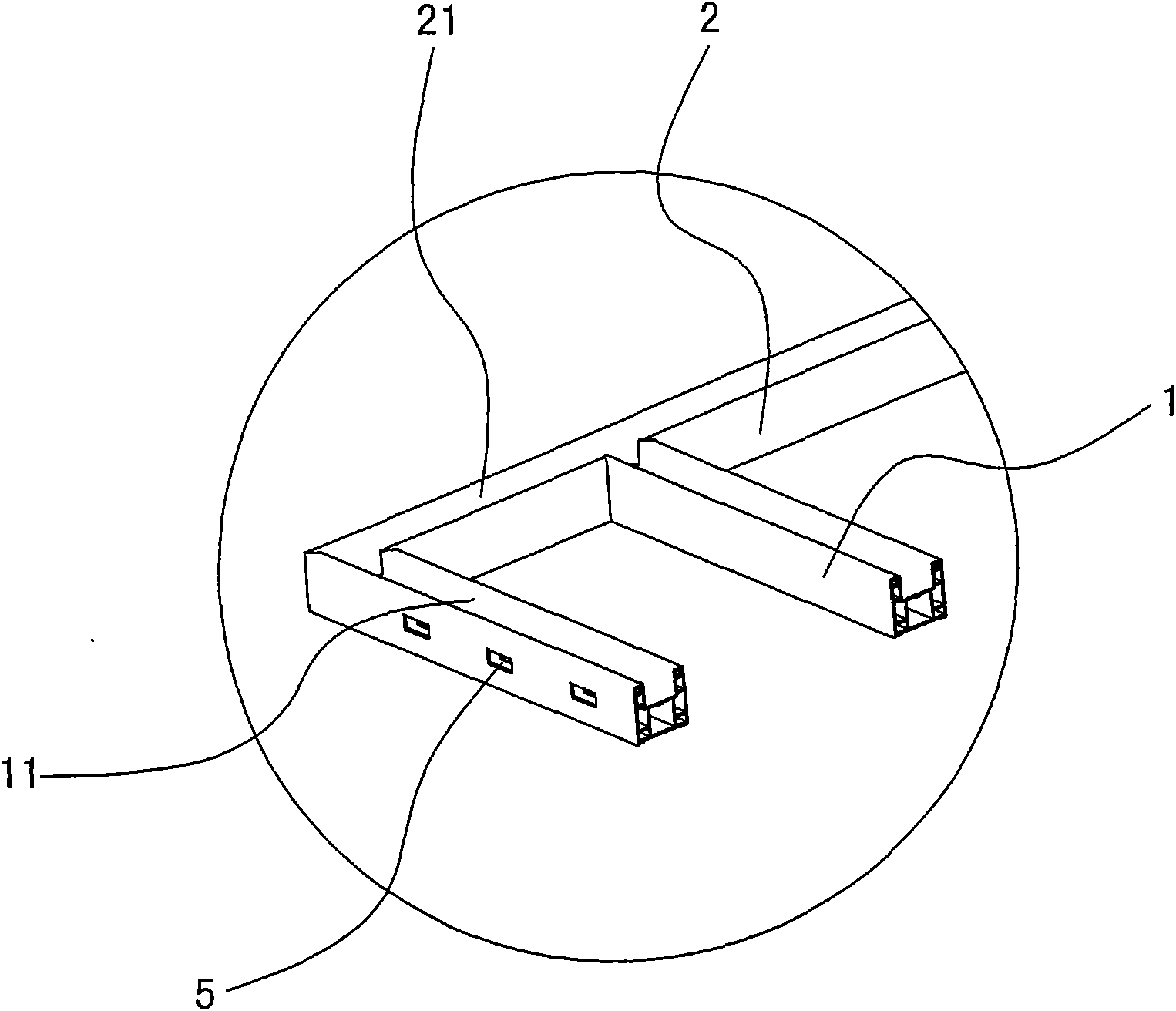

[0011] The invention relates to a profile frame of a photovoltaic power generation solar cell module, such as Figure 1-Figure 4 As shown, the frame is composed of plastic cross bars 1 and longitudinal bars 2, which are characterized in that the plastic cross bars 1 and plastic longitudinal bars 2 are welded to each other to form a frame, and the number of plastic cross bars 1 is 3 or 3 Above, constitute 2 or more than 2 battery assembly frames 3, battery assembly 4 is installed in each battery assembly frame, in the plastic horizontal bar 1, be shaped on the horizontal guide groove 11, in the plastic longitudinal bar 2, be shaped on the longitudinal The diversion groove 21, the transverse diversion groove 11 and the longitudinal diversion groove 21 communicate with each other, and the diversion groove is formed with at least one water outlet hole 5. This scheme adopts prefabricated plastic profiles, which are cut and processed into plastic horizontal bars 1 and plastic longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com