Double-winding permanent magnet motor

A permanent magnet motor and double-winding technology, which is applied in the direction of motors, windings, synchronous motors with rotating armatures and stationary magnets, etc., can solve the problems of difficult to meet the acceleration requirements of vehicle starting, the reduction of motor starting torque, and the difficulty of high-speed motors Operation and other problems, to achieve good regenerative braking effect, strong overload capacity, and reduce the burden of mechanical brakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

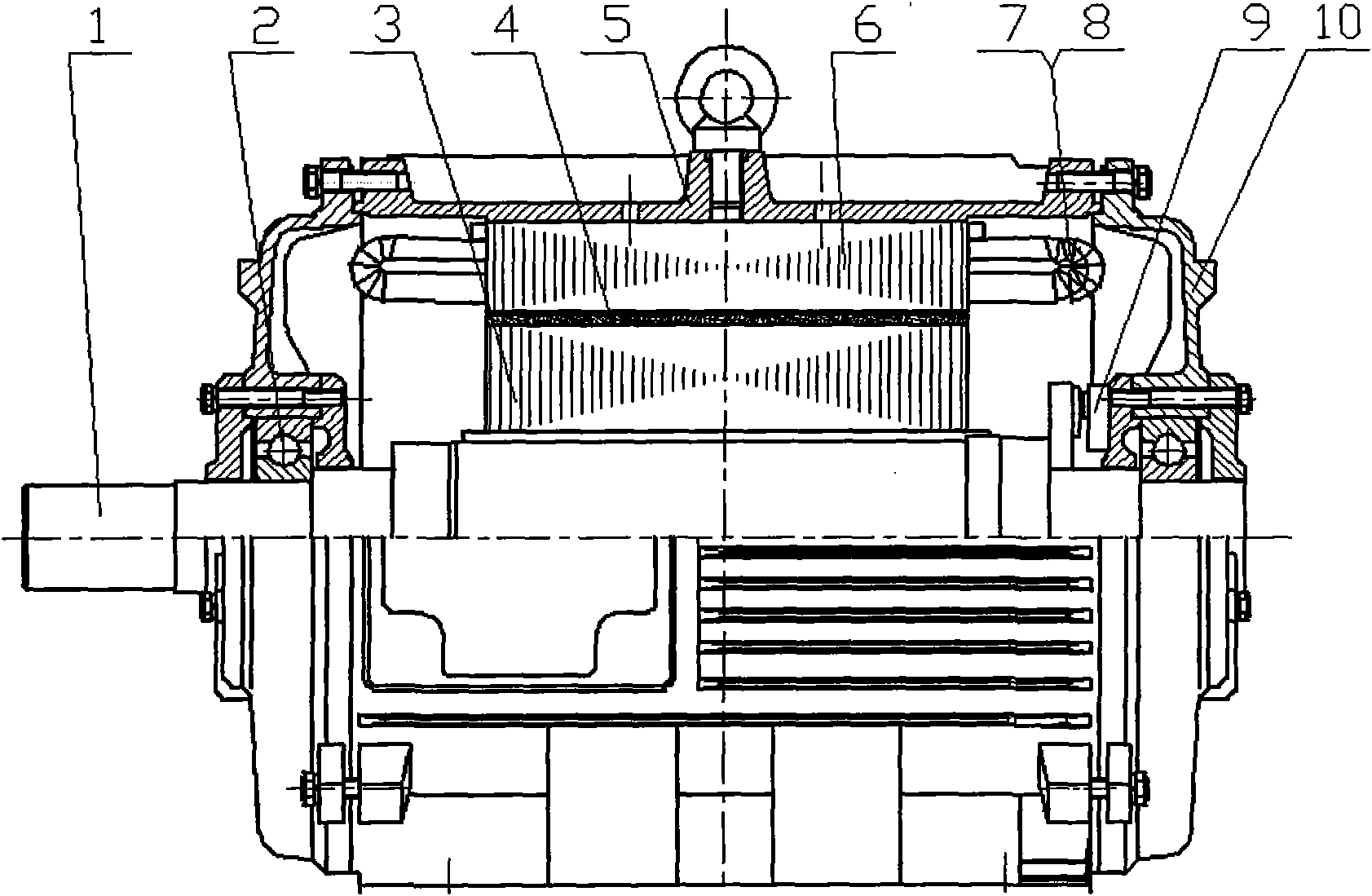

[0010] Such as figure 1 As shown, the rotor core 3 is stacked as a whole and then press-fitted on the motor shaft 1, the magnetic steel 4 is pasted on the rotor core 3, the bearing 2 is mounted on the motor shaft 1, and the stator core 6 is press-fitted on the stator casing 5 Inside, the high-torque winding 7 and the high-speed winding 8 are installed in the slot of the stator core 6, the outer end of the motor end cover 10 is connected with the stator casing 5, and the inner end is connected with the outer ring of the bearing 2, so that the motor becomes a Overall, the rotating part of the position detection device 9 is mounted on the motor shaft 1 , and the stationary part of the position detection device 9 is mounted on the motor end cover 10 .

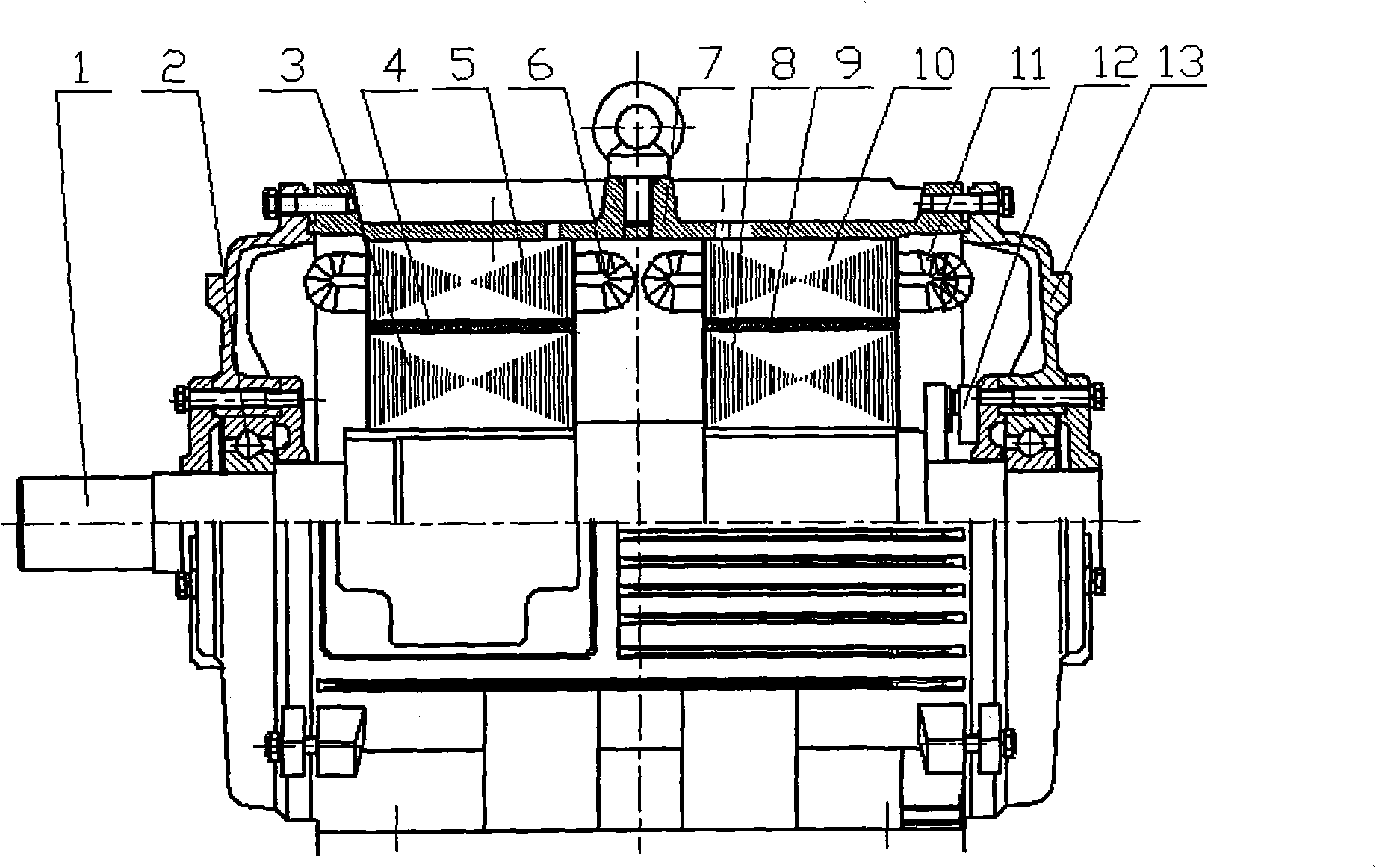

[0011] Another structural form of the present invention is as figure 2 As shown, the motor consists of two sets of stator and rotor cores, independent high-torque windings 7, high-speed windings 8 and related components, high-tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com