Method and apparatus in pneumatic material conveying system

A conveying system and conveying pipe technology, applied in conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problems of increasing system complexity and cost, troublesome conveying system cleaning, dust and fine particles, etc., and achieve easy cleaning and handling. and effective, fast and efficient cleaning process, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

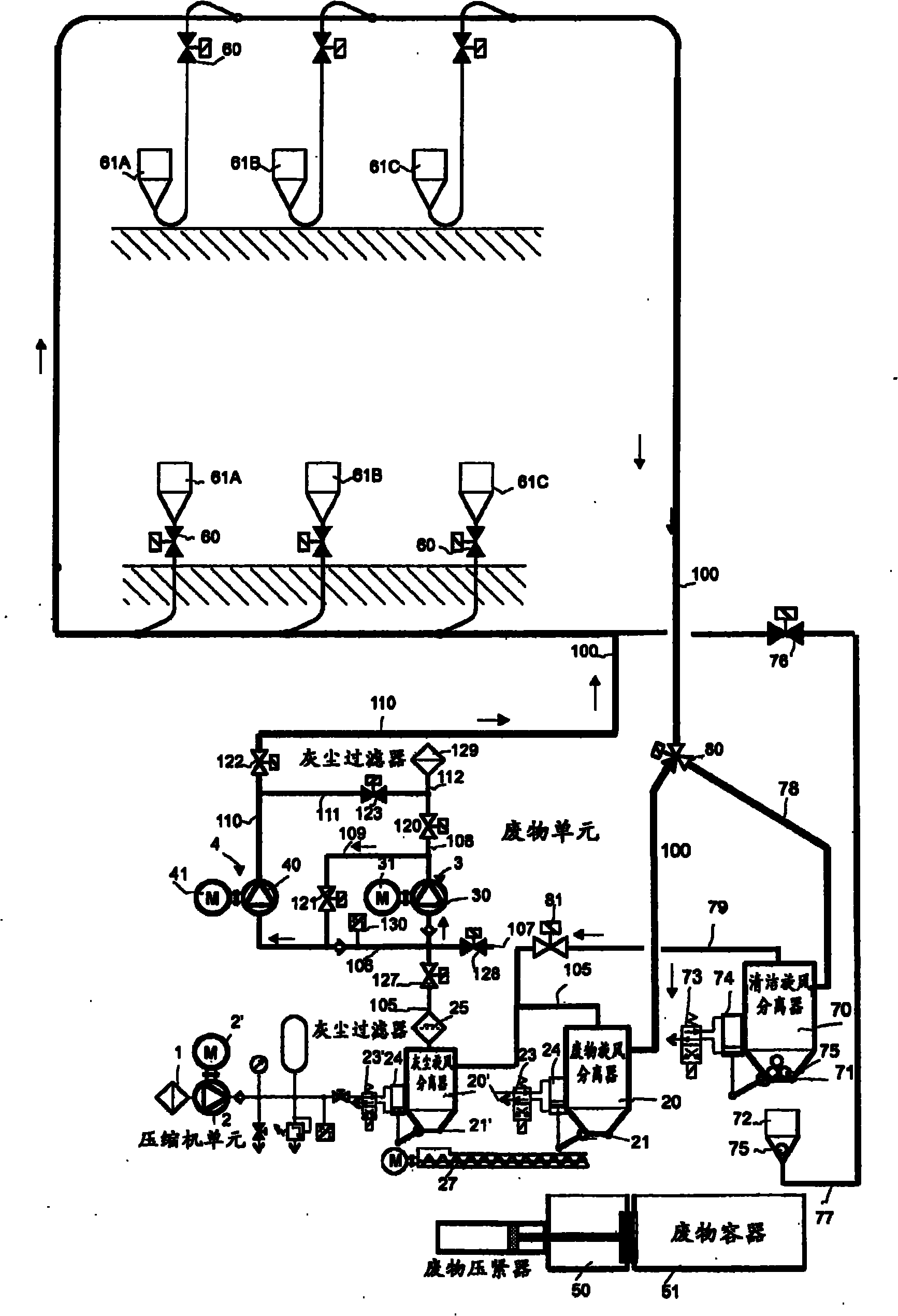

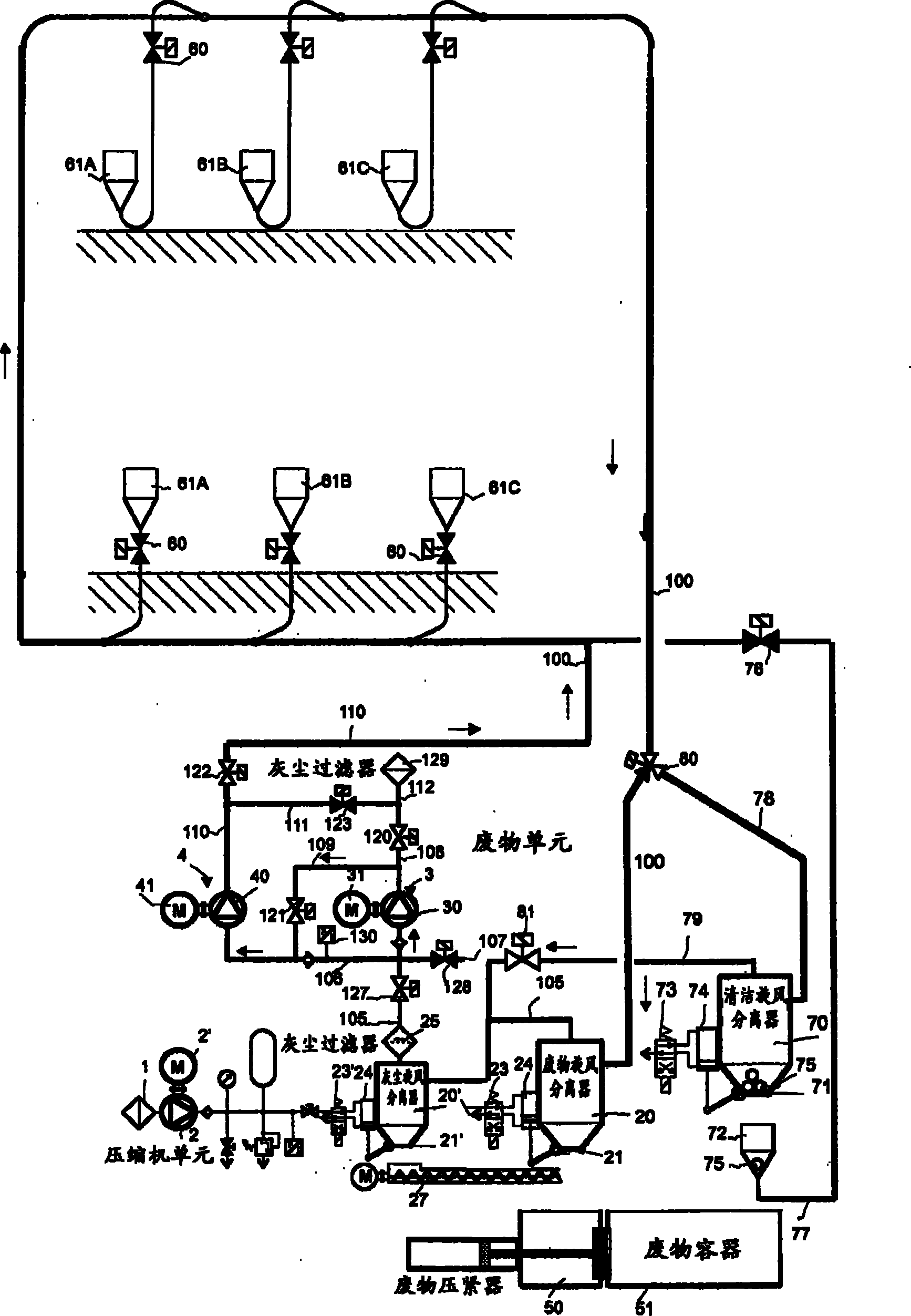

[0012] The drawings represent simplified material conveying systems, in particular waste conveying systems, using the method and device according to the invention.

[0013] exist figure 1 , reference numerals 61A, 61B, 61C denote supply stations for material to be conveyed, in particular waste material, from which station material to be conveyed, in particular waste material such as household waste, is to be supplied to the conveying system. The system may comprise a plurality of supply stations 61 from which the material to be conveyed is supplied to the conveying line 100 . Generally, the transfer pipeline includes a main transfer pipe 100, into which a plurality of branch transfer pipes can be connected, and a plurality of supply stations 61 can be connected to the main transfer pipe 100 through supply pipes. The supplied material is conveyed along the conveying line 100 to one or more separator devices 20 where the conveyed material can be separated from the conveying air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com