Hay knife for lawn hay mower without tool holder

A lawn mower and lawn mower technology, applied in lawn mowers, harvesters, applications, etc., can solve the problems of no safety protection, large moment of inertia, and high power consumption, and achieve weight reduction, power consumption reduction, and construction cost. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

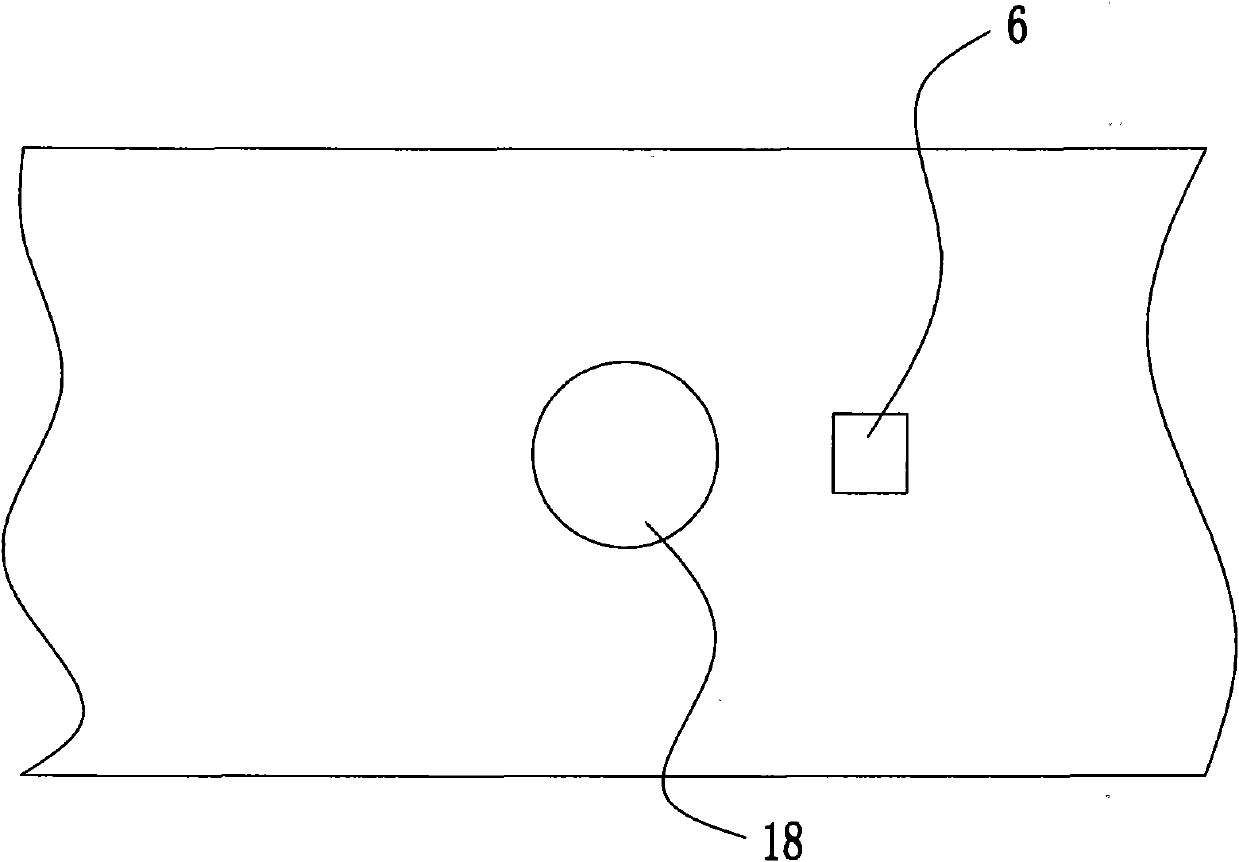

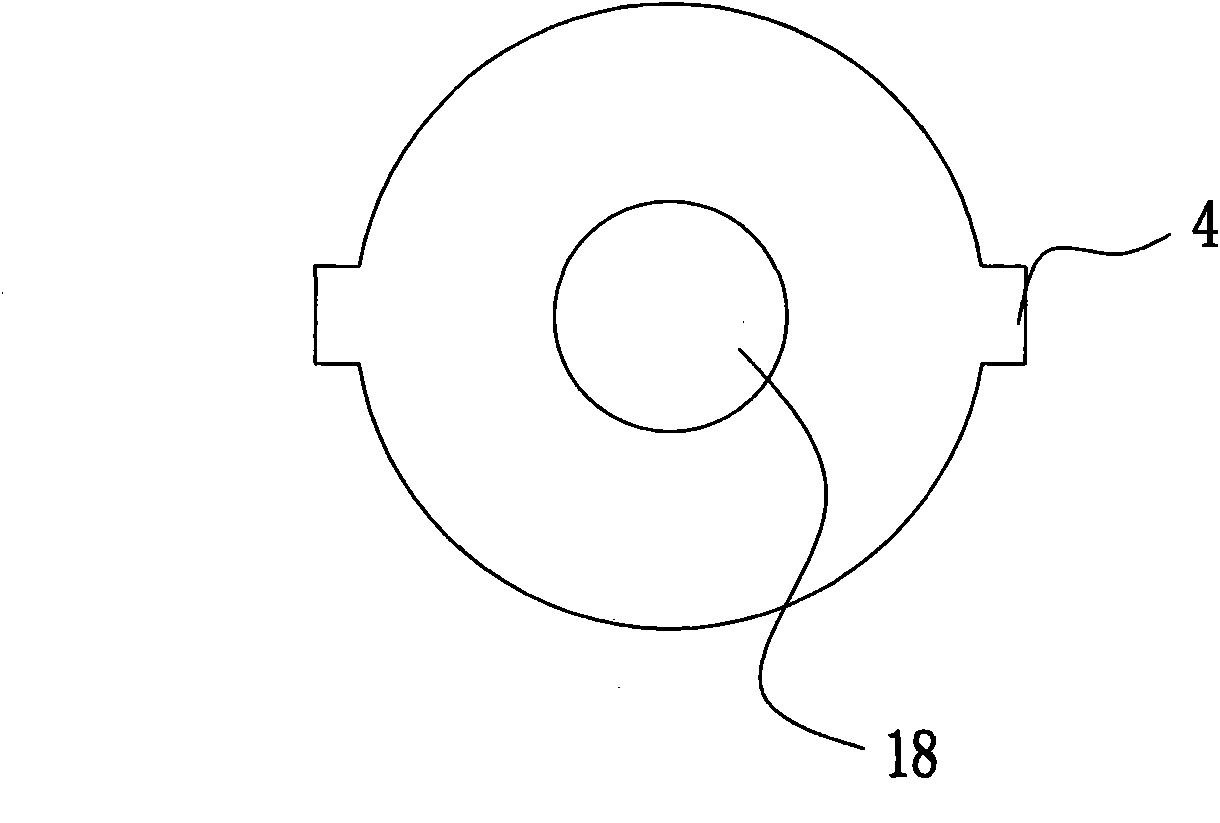

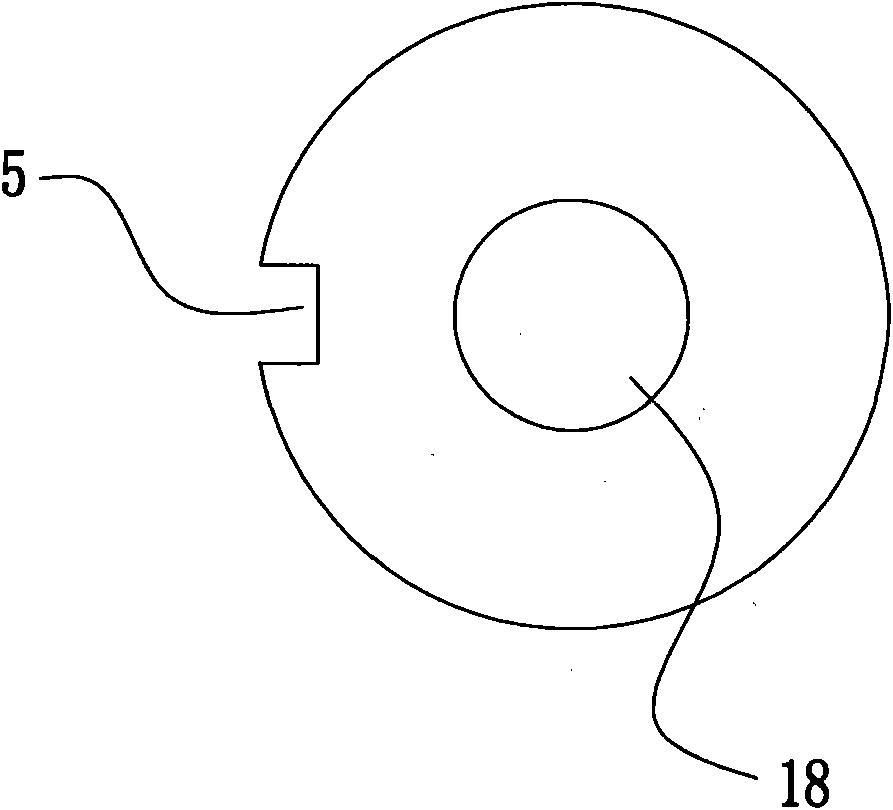

[0037]To improve the mowing device of the engine main shaft, at first it is to manufacture a lawn mower without a knife seat with a mowing knife. The material of the steel plate suitable for making knives should be optimized, and edge folds and multiple protrusions should be made in order to improve the modulus of material mechanics and reduce the thickness of the steel plate; suitable pre-heat treatment such as semi-annealing and tempering treatment, stretch forming or Hot forming, stamping forming again, make dimple (2), key (1), keyway (3), make the inner diameter of described dimple (2) be equal to or the tolerance is slightly larger than the outer diameter of engine main shaft. Then carry out normalizing and aging treatment; and grinding correction and oiling or blackening treatment. There is a hole in the bottom of the pit (2) so as to pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com