Roller-lifting proportional and synchronous hydraulic control system

A technology of hydraulic control system and lifting hydraulic cylinder, which is applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problems of inconvenient displacement control, etc., and achieve convenient and fast adjustment, high precision displacement control, and high synchronization precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

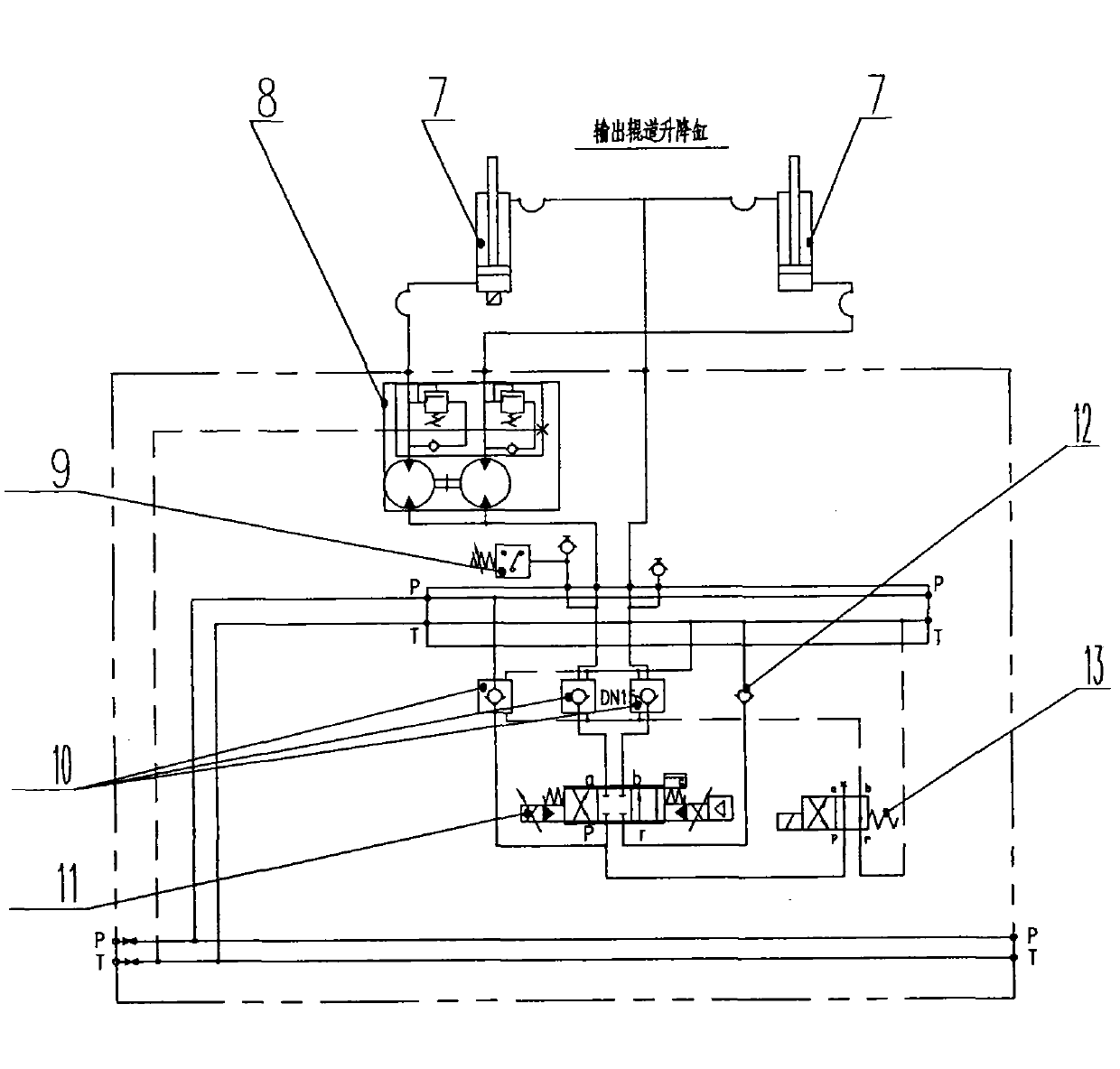

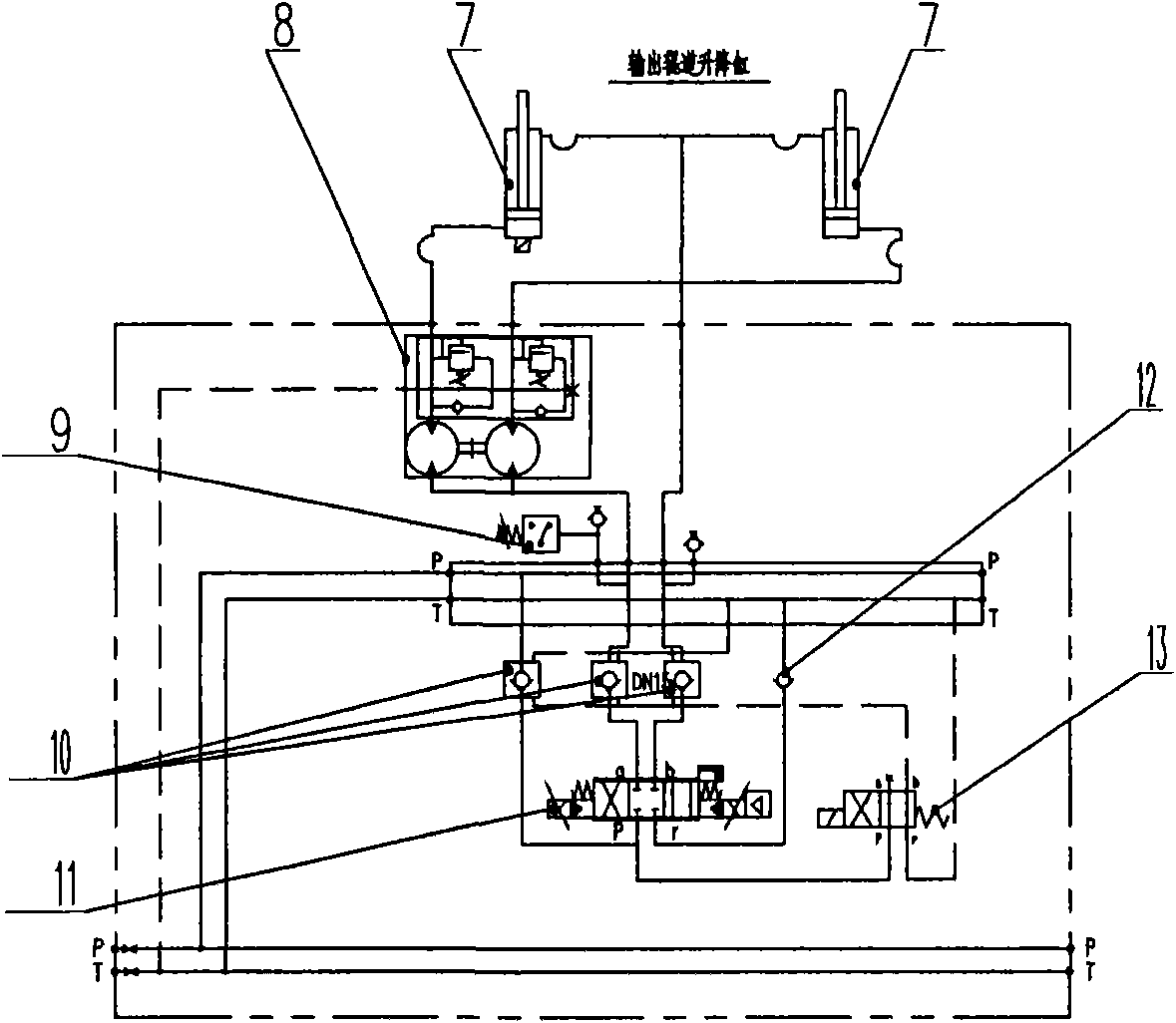

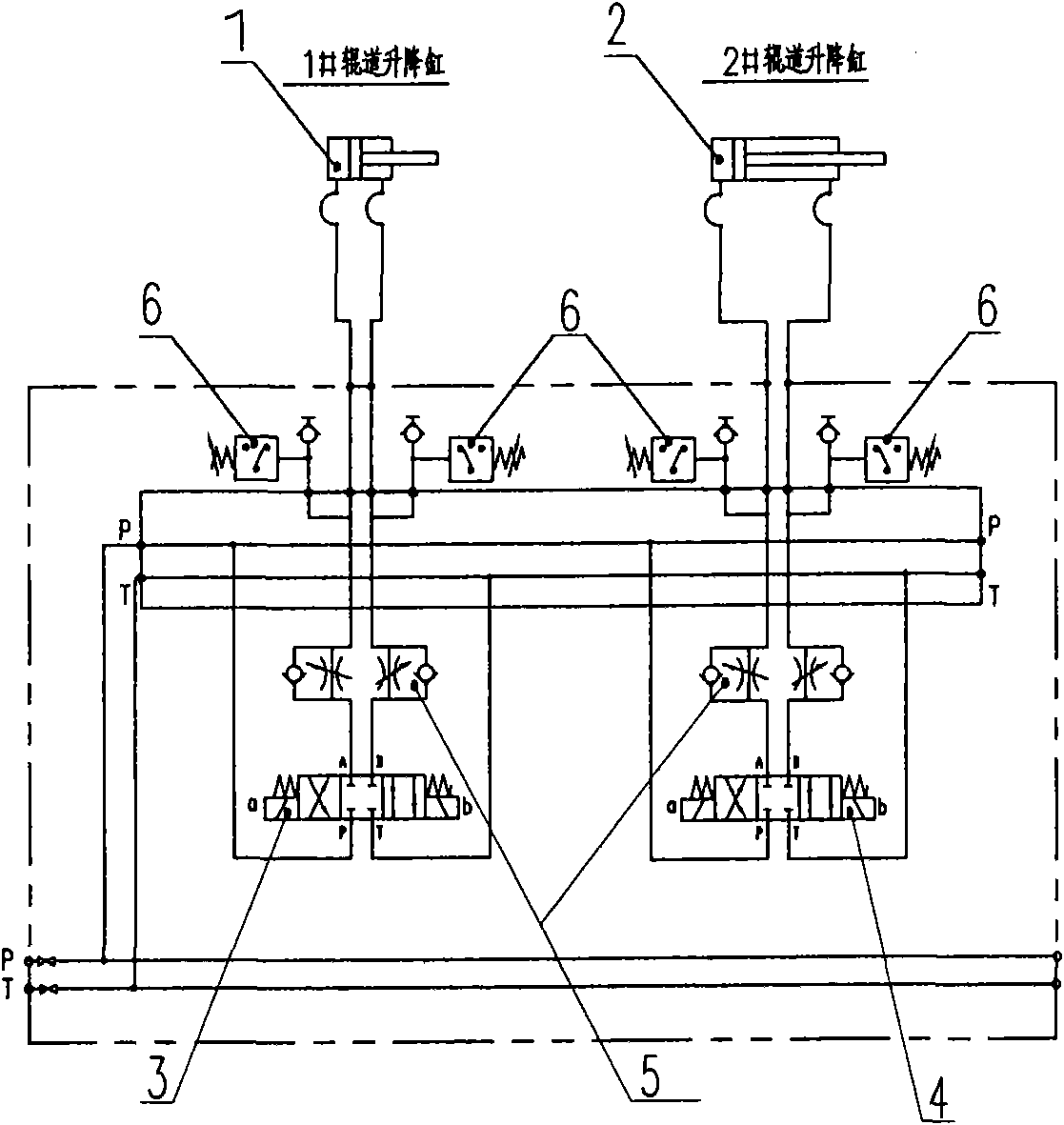

[0016] Such as figure 2 As shown, a proportional synchronous hydraulic control system for roller table lifting is composed of a proportional valve 11, a hydraulic control check valve 10, a reversing valve 13, a pressure relay 9, a synchronous motor 8, a check valve 12 and two rollers There are three hydraulically controlled one-way valves 10, which are respectively connected to the p port, a port and b port of the proportional valve 11, and the a port of the proportional valve 11 passes through the hydraulic control The check valve 10 is connected to the pressure relay 9 and the oil inlet of the synchronous motor 8, and the two oil outlets of the synchronous motor 8 are respectively connected to the piston chambers of the two roller lift hydraulic cylinders 7, The piston rod cavity of the roller table lifting hydraulic cylinder 7 is connected in parallel to the b port of the proportional valve 11 through the hydraulic control check valve 10, and the b port of the reversing va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com