Device and method for controlling liquid level of liquid electroslag continuous casting slag pool

A control device and continuous casting slag technology, which is applied in the field of metal electroslag remelting, can solve the problems of environmental protection and low maintenance costs, and achieve the effect of low maintenance costs and simple control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

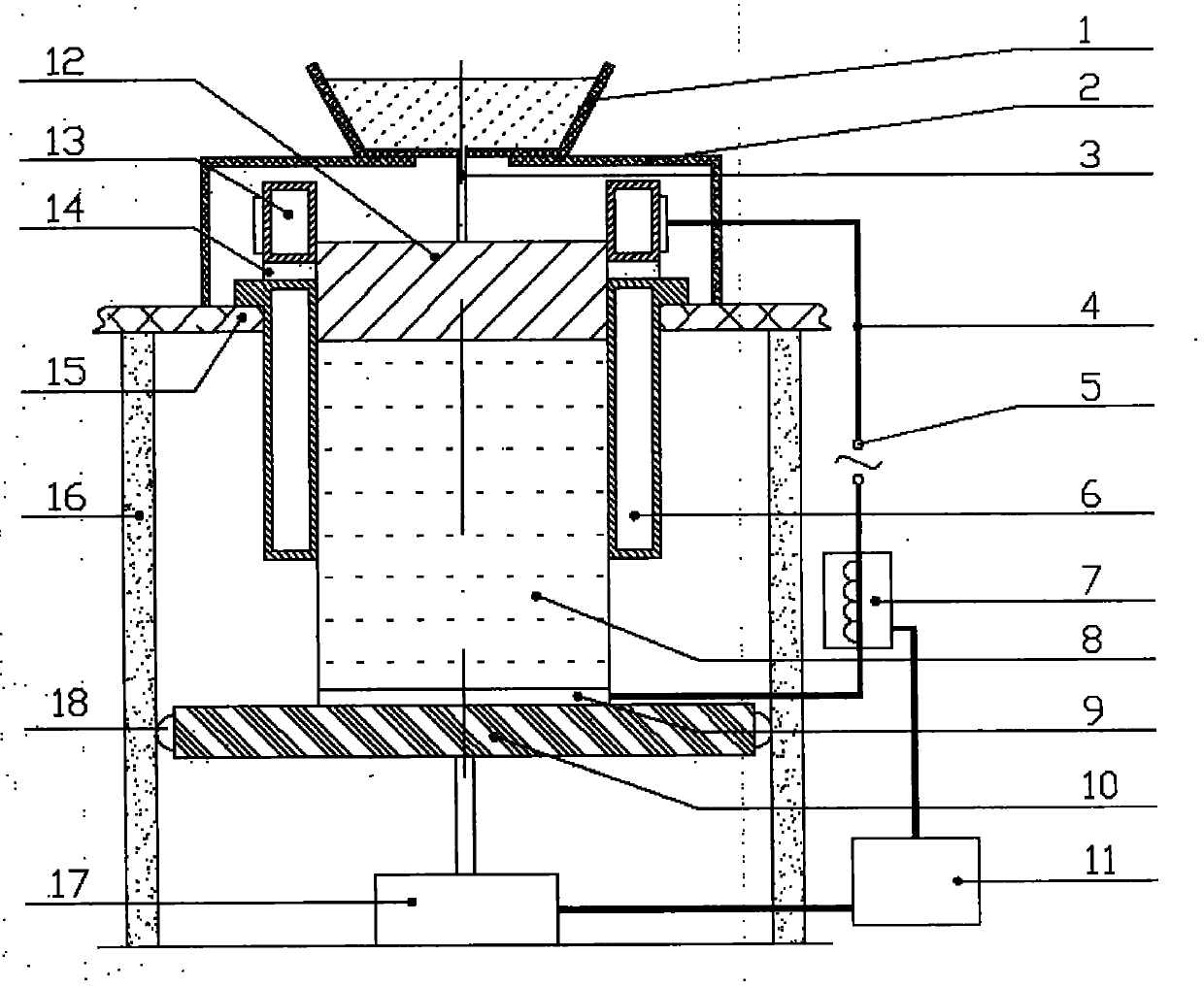

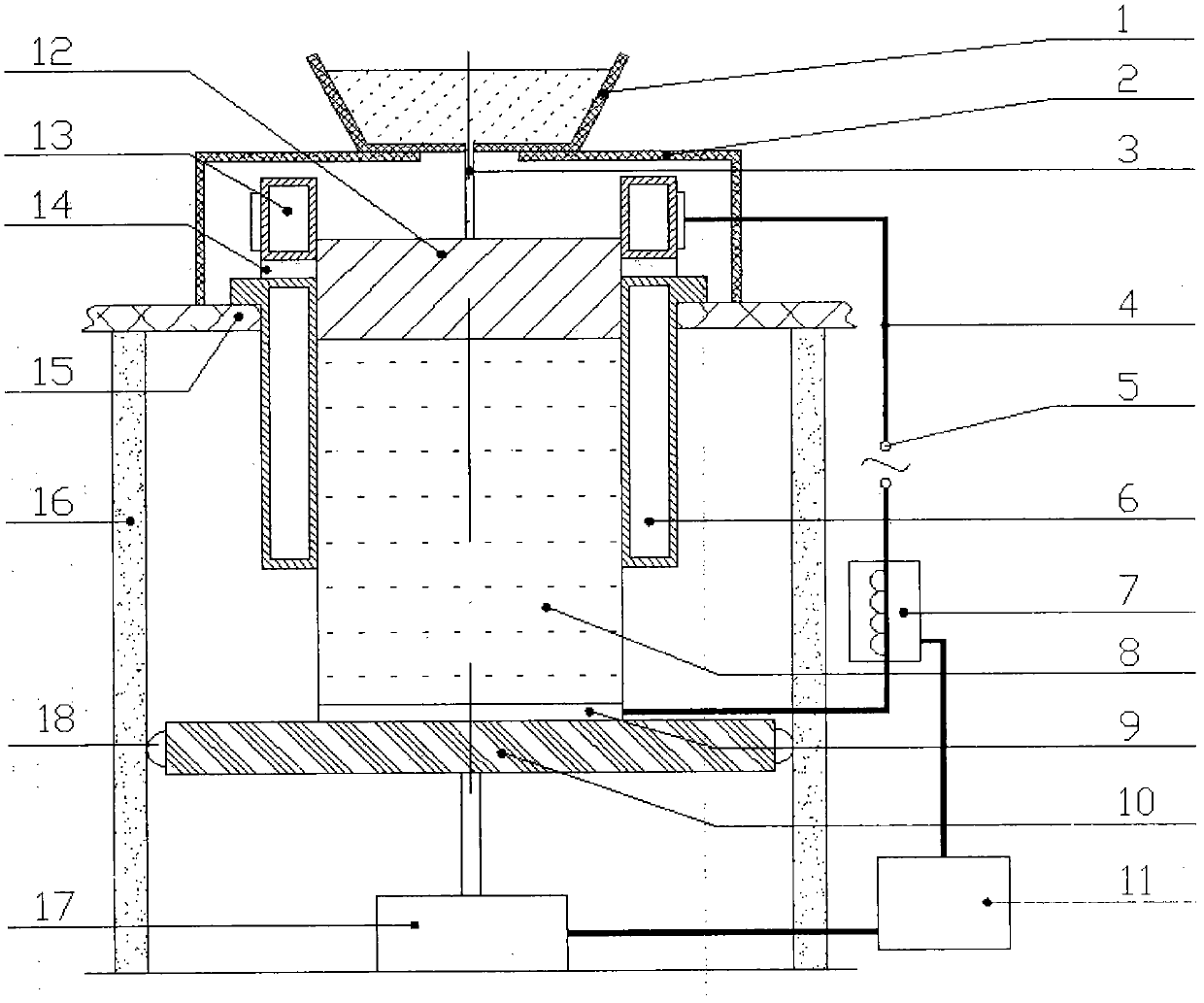

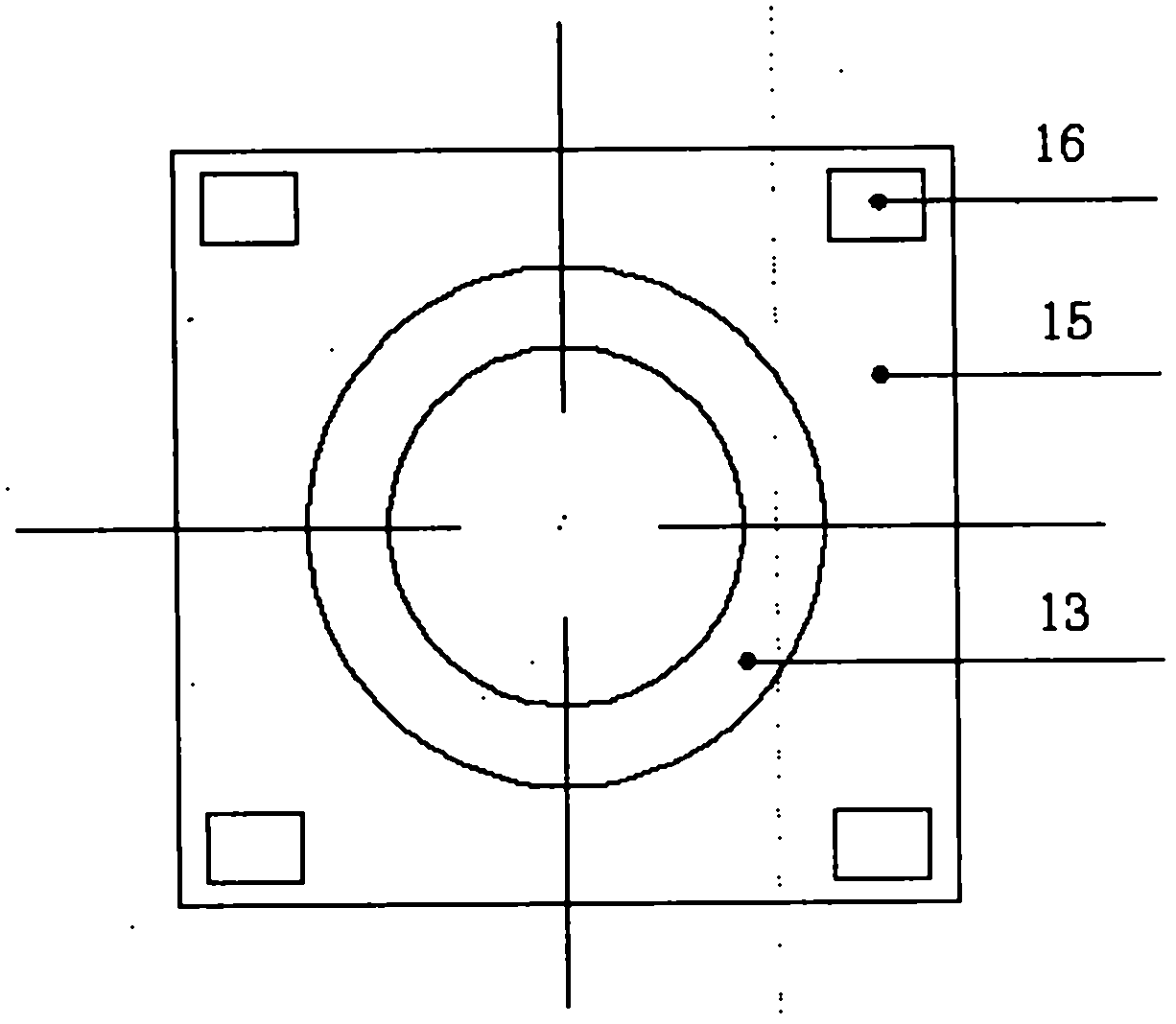

[0018] A device and method for controlling the liquid level of a liquid electroslag continuous casting slag pool according to the present invention are described in conjunction with embodiments and accompanying drawings.

[0019] In this embodiment, the model ZB01 is selected for the casting tundish, the model ZBJ01 is selected for the tundish bracket, the model WCCB is selected for the high-current water-cooled cable, the model DCYC is selected for the lower crystallizer, the model HAL is selected for the high-current detection element, and the model DWT is selected for the dummy conductive bottom water tank. Select the model ESRLM-CV10.02 for the controller, select the model UCYC for the upper crystallizer, and select the model Y180M for the spindle pulling motor.

[0020] The control device of the liquid level of the liquid electroslag continuous casting slag pool of the present invention is as follows: figure 1 with figure 2 As shown, it includes an AC power supply 5, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com