Method for manufacturing special sliders for rotary compressors by adopting 9Cr18 or 9Cr18Mo stainless steel

A rotary compressor, 9cr18 technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of energy consumption and cost, stalled rotor, air conditioner can not work, etc., to save energy and cost, nitriding performance Good, small amount of deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

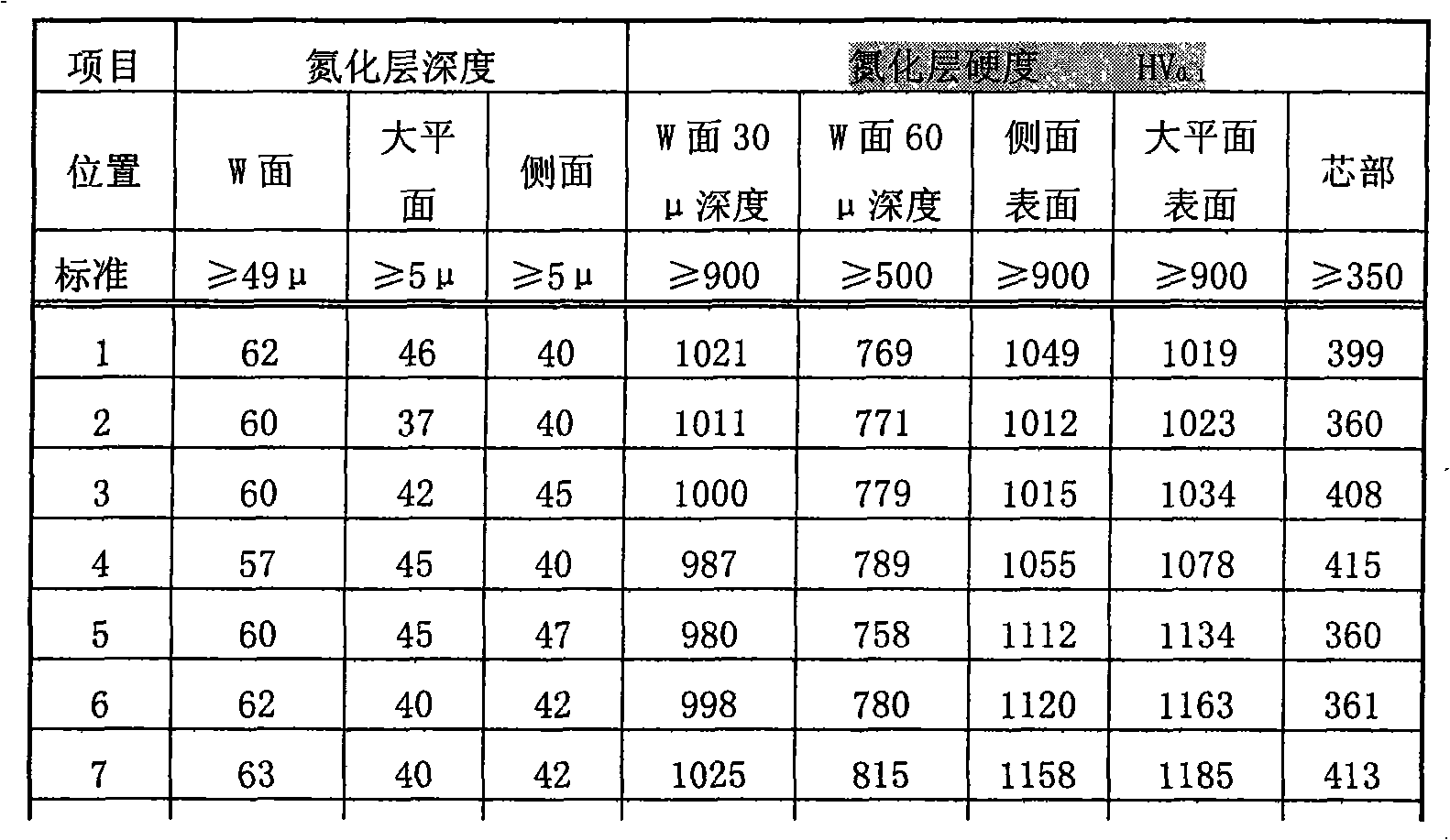

Examples

Embodiment Construction

[0024] First select the appropriate profile, then cut the material according to the specification and size of the drawing, and then put it on the machine tool for rough cutting. After vacuum quenching and tempering, finish machining is carried out. Then through rolling throwing, cleaning, and then enter the liquid nitrocarburizing salt bath for treatment.

[0025] The liquid nitrocarburizing salt bath treatment consists of the following steps: first, use aviation kerosene or alcohol to remove the oil and dirt on the surface of the parts; according to the special sliding parts of different sizes and specifications, select different special workstations for vertical placement and loading; The preheating temperature is selected to be 350°-420°C, and the preheating time is 10-20 minutes; for salt bath treatment, the treatment temperature is 550-580°C. According to the different specifications of the special sliding parts and the size of the processing capacity, the holding time o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com