Water hyacinth combined salvage processing device

A disposal device and salvage device technology, which is applied in the direction of transportation and packaging, naval ships, special-purpose ships, etc., can solve the problems of high labor intensity, discontinuous disposal, loud noise, etc., achieve low manual labor intensity, reduce work blind spots, reduce direct cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

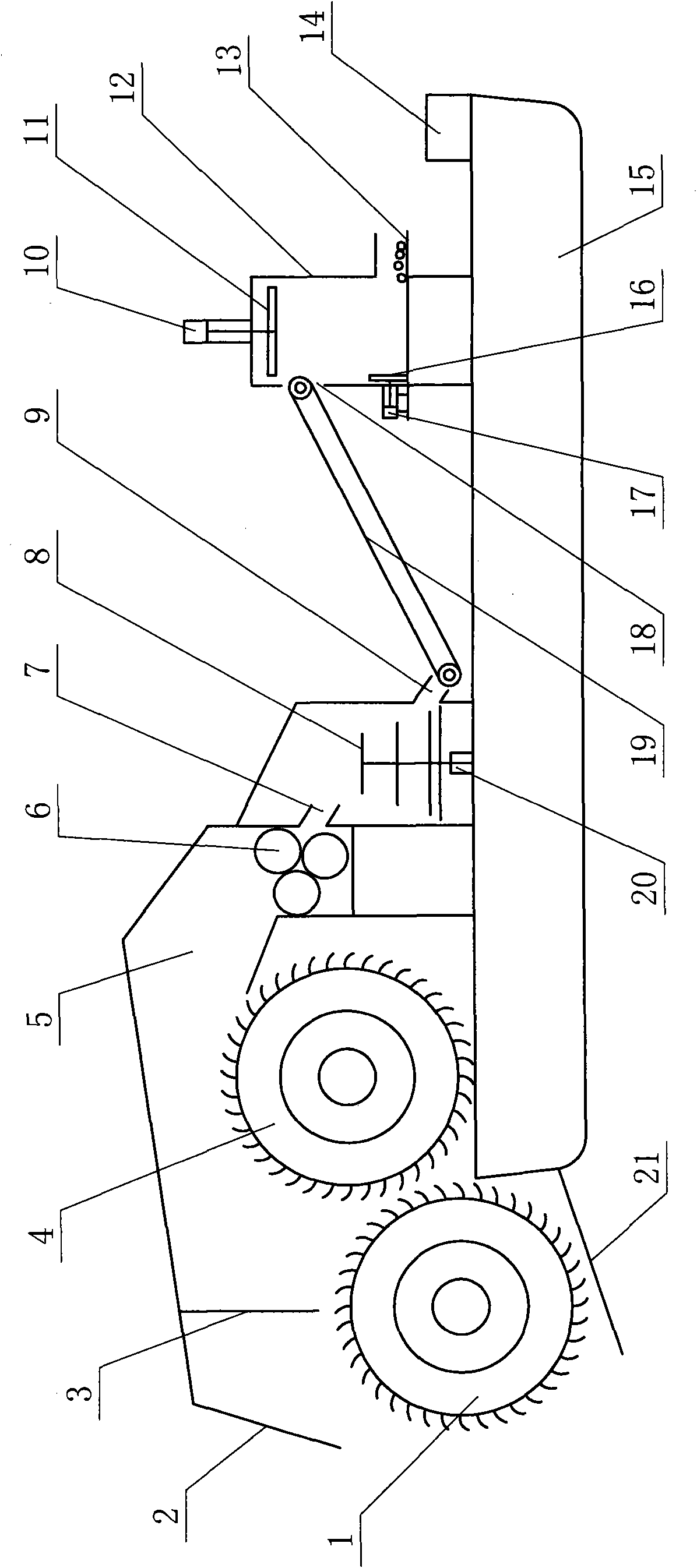

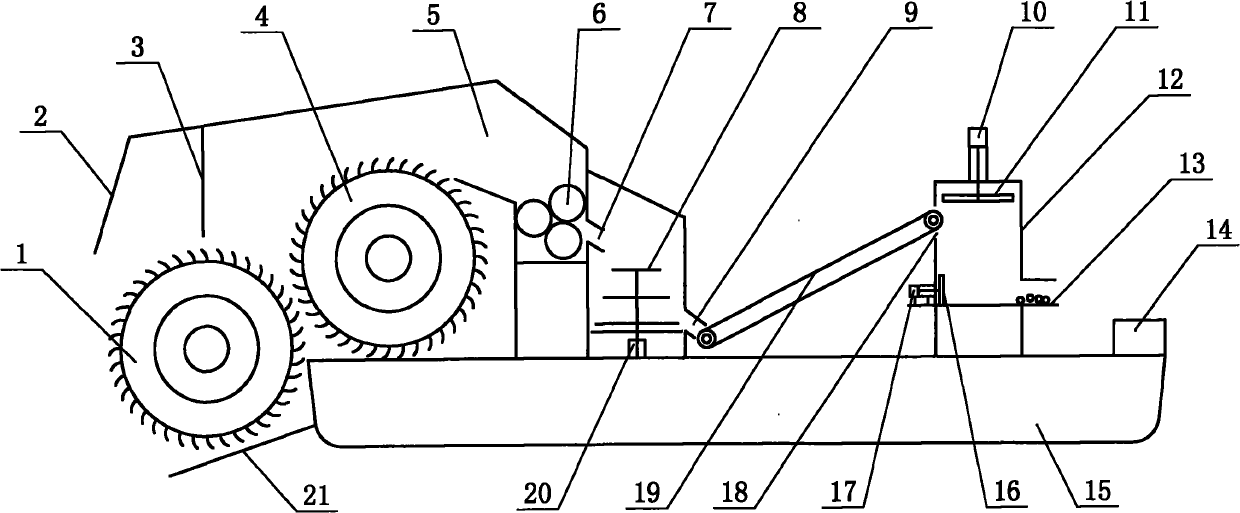

[0020] refer to figure 1 A combined salvage and disposal device for water hyacinths of the present invention, comprising a mobile water surface working platform 15 fixed with a power propulsion device and an electric device 14, the working platform 15 is sequentially provided with a salvage device, a dehydration device, a crushing device and a compression packing device, The salvage device is arranged on the front end of the working platform 15, and the discharge end of the salvage device corresponds to the dehydration feed inlet 5 in the dehydration device, and the dehydration discharge port 7 in the dehydration device corresponds to the feed inlet in the crushing device. The crushing outlet 9 in the device corresponds to the compression inlet 18 in the compression packaging device, and the electric device 14 is connected with the salvage device, the dehydration device, the crushing device and the compression packaging device respectively, and the electric device 14 adopts die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com