Feeding mechanism for feeding polytetrafluoroethylene membrane into chain clamping device

A technology of polytetrafluoroethylene film and feeding mechanism, which is applied in the directions of transportation and packaging, winding strips, and thin material processing, etc., which can solve the damage of the base tape, the inability to produce thick polytetrafluoroethylene film, and the base tape is easy to wrinkle and other issues to achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] One embodiment of the present invention is as follows.

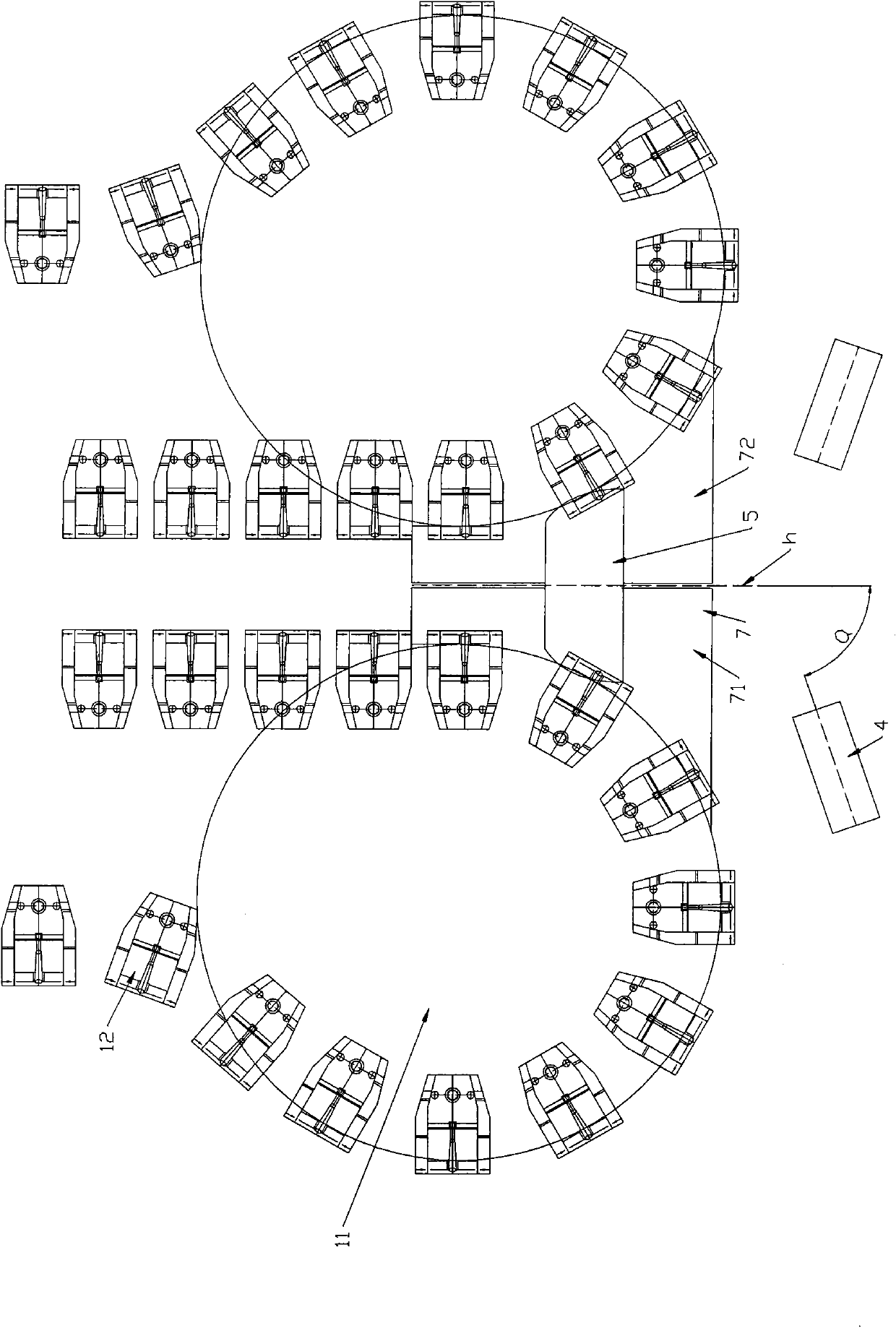

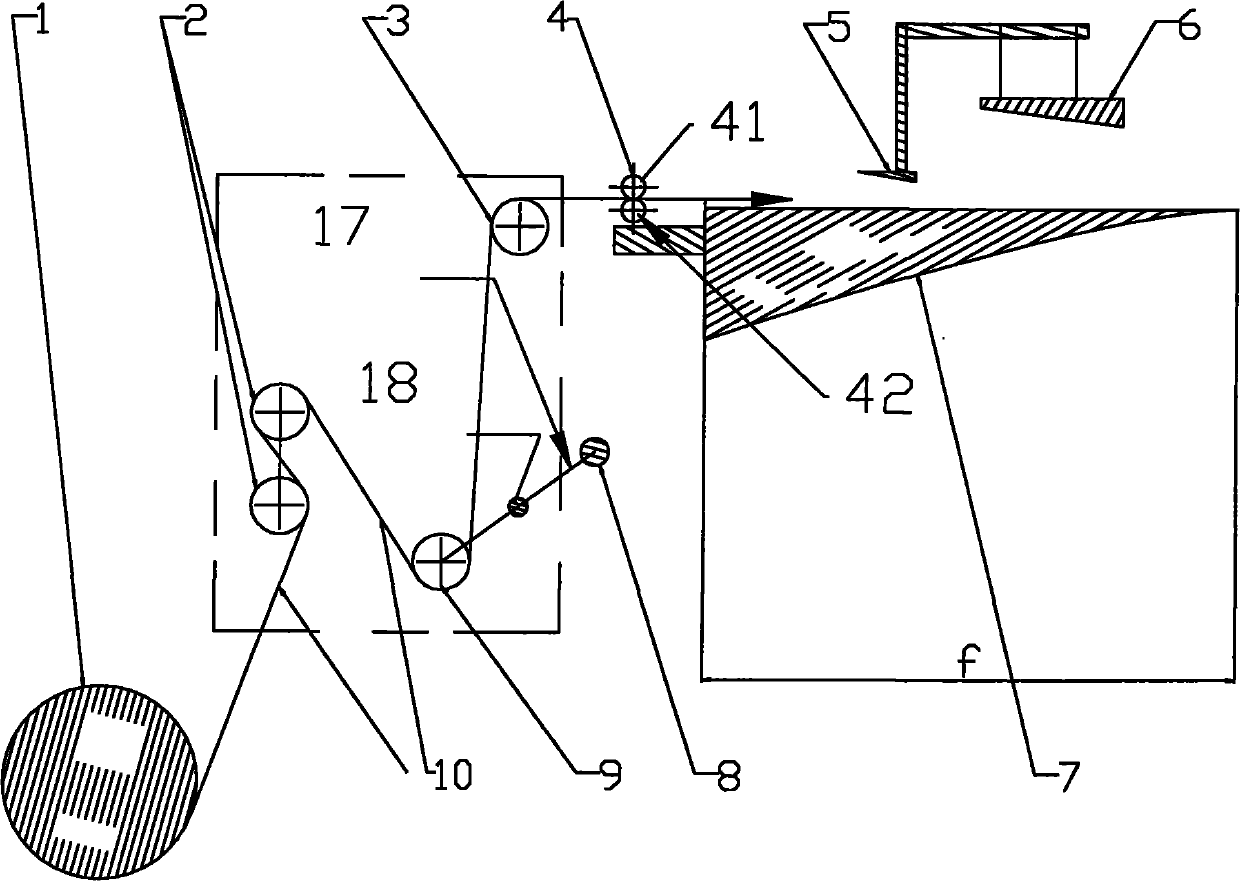

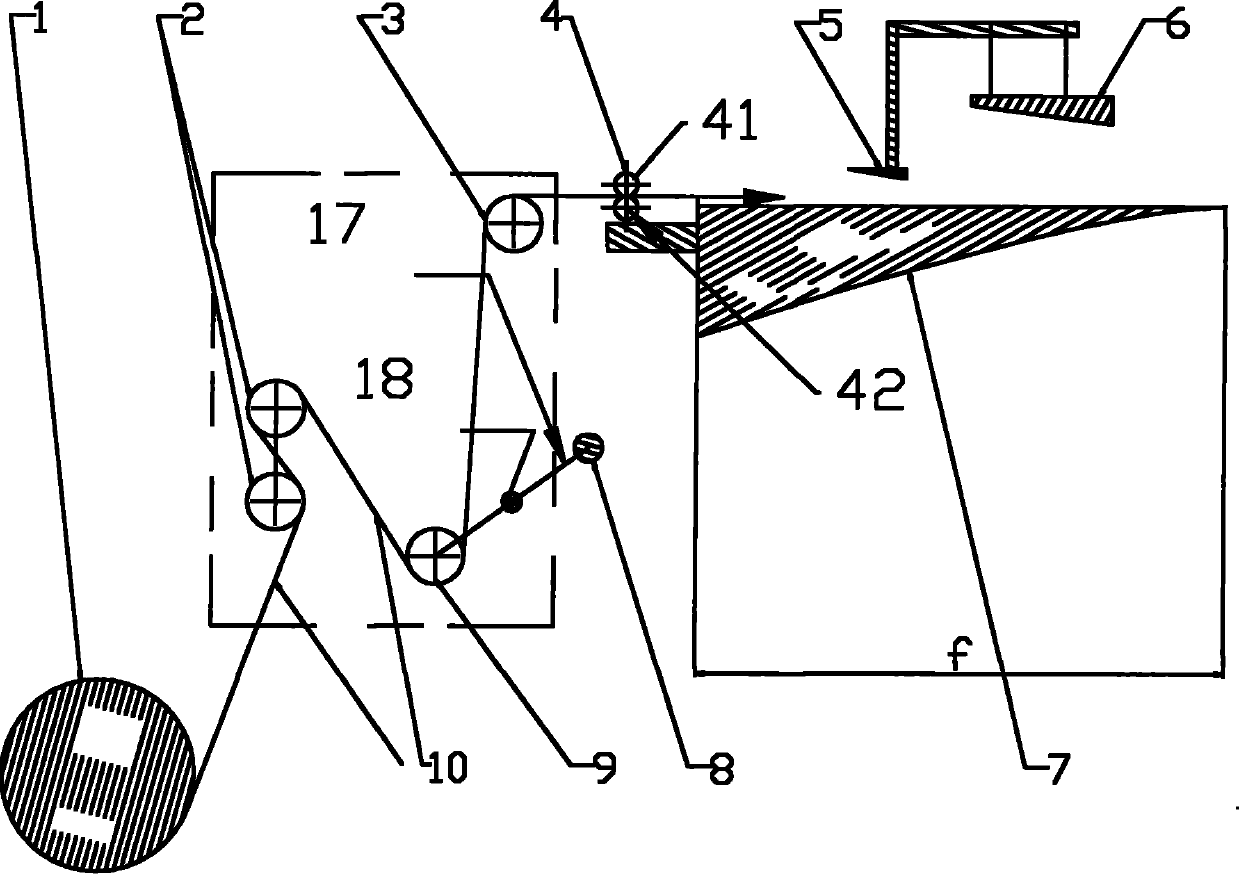

[0019] see figure 1 , 2 , 4. The feeding mechanism includes a supporting plate 7 arranged between opposite static clip plates 16, and a pressing plate 5 is arranged above the supporting plate 7. The pressing plate 5 is composed of a middle part 52 which is high in the middle and flash parts 52 which are low on both sides. The gap b between the flash portion and the supporting plate 7 is 0.01-2 mm. The width c of the flash portion on each side is 1-3 cm, and the middle portion is higher than the flash portion by e=2-5 mm. The shape of pressing plate 5 is slightly " few " shape, and middle part is slightly higher, is beneficial to longitudinally pulling baseband to pass;

[0020] There is a gap between the pressing plate 5 and the supporting plate 7, and the feeding mechanism also includes an unwinding device for sending the polytetrafluoroethylene film (base tape) 10 into the gap at a constant line speed and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com