Heat pump type circulation heat pipe radiator

A technology of circulating heat pipes and radiators, which is used in lighting and heating equipment, cooling/heating devices for lighting devices, lighting devices, etc. Stable long-term work, improve cycle speed, and meet the effect of beautiful design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

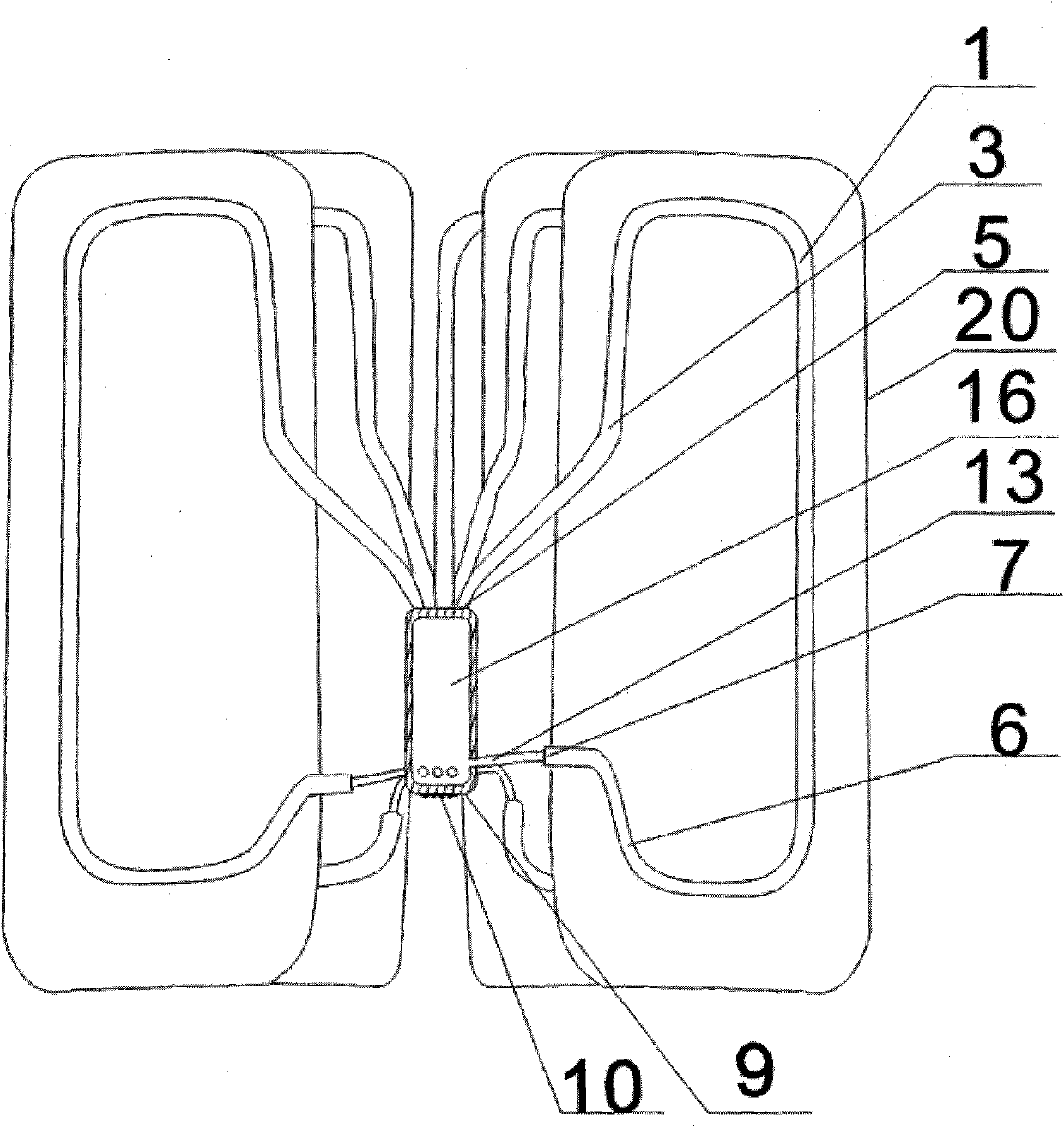

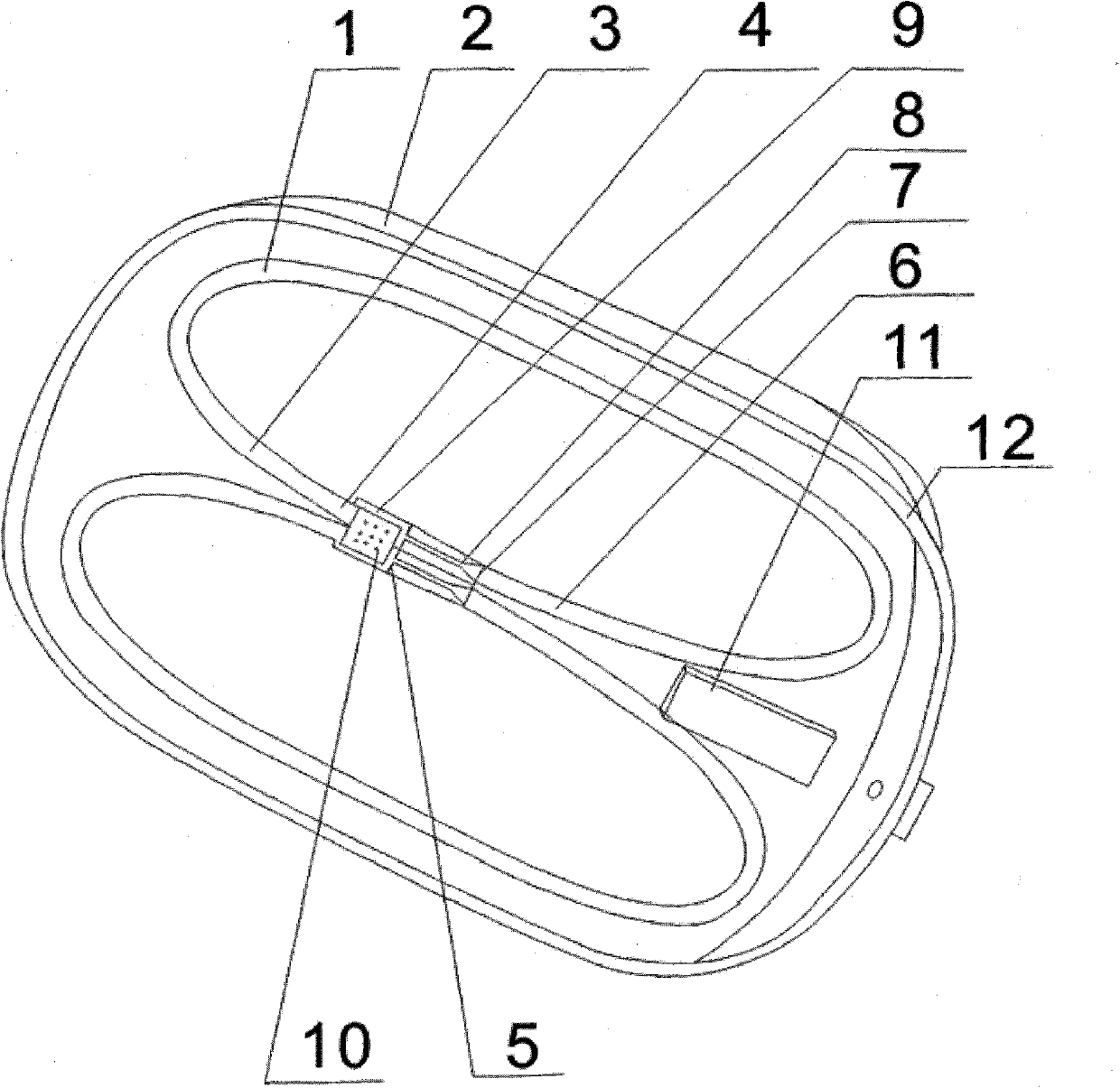

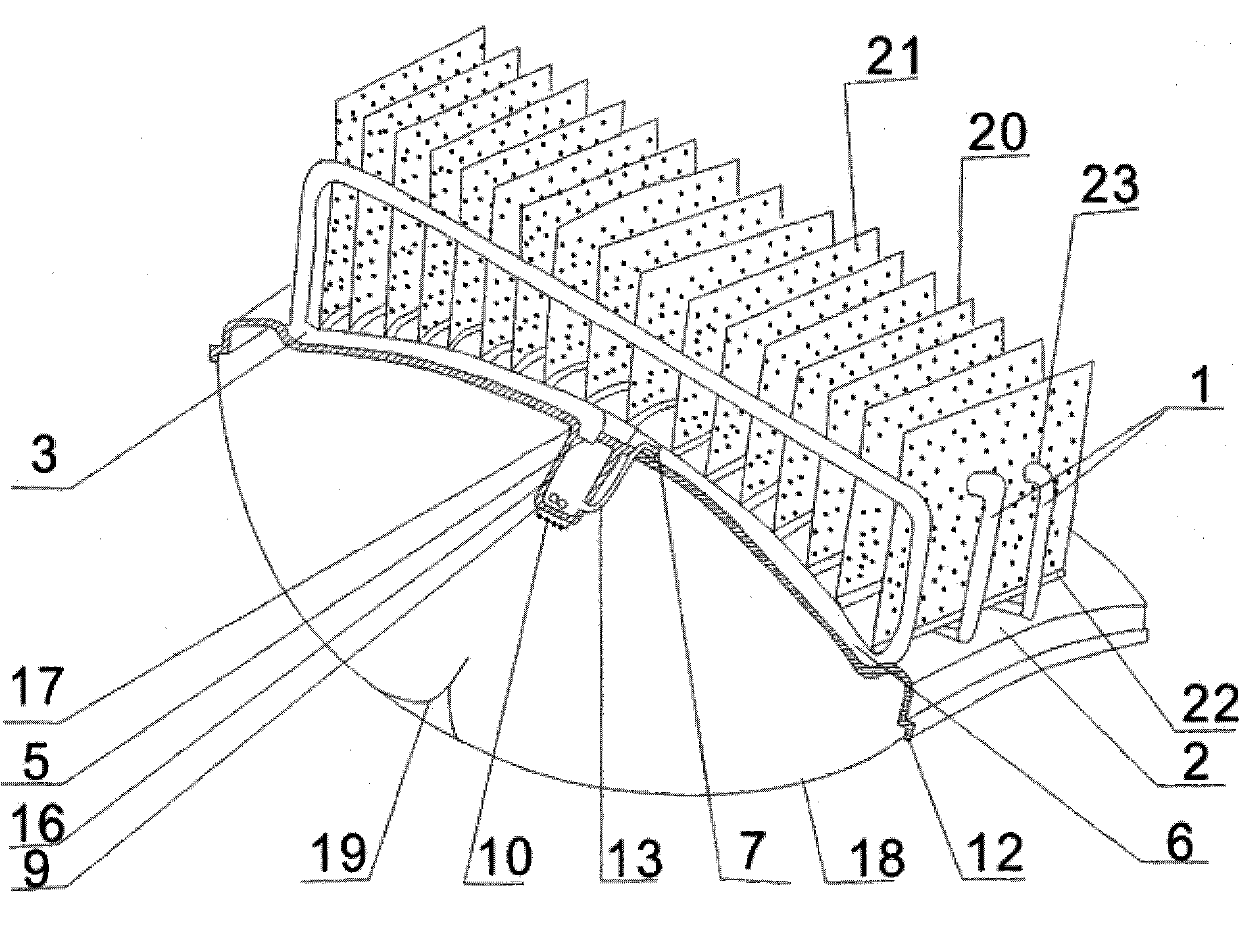

[0020] figure 1 The first embodiment of the present invention is viewed from above, and the circulating heat pipe 1 made of good conductor material is completely wrapped around the inner surface of the lamp housing 2, and the two are all welded to each other. The heating section 4 of the evaporating section 3 of the circulating heat pipe The pipe port of the heat pipe is the first port 5, and the end pipe port of the condensing section 6 of the circulation heat pipe is the end port 7, and the first and the end ports are connected through the throttle valve 8, thereby forming a sealed circulation heat pipe pipeline, and the heat of the heat circulation heat pipe The welding layer with good heat conduction is quickly transferred to the lamp housing stamped by good heat conduction material to form a matching evaporation section and condensation section. The lamp body shell forms an inclined angle with the horizontal plane, which is convenient for the condensed working fluid to use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com