Method for detecting quality of concrete-filled steel tubular column through ultrasonic waves

A technology of steel pipe concrete column and quality inspection method, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problems of difficult interpretation of the first wave sound, the influence of waveform noise signal, and unobvious features, so as to achieve accurate and reliable detection strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

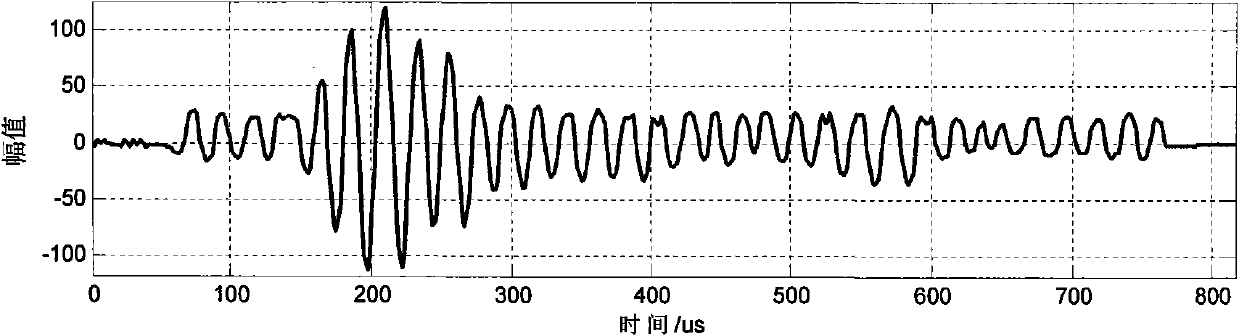

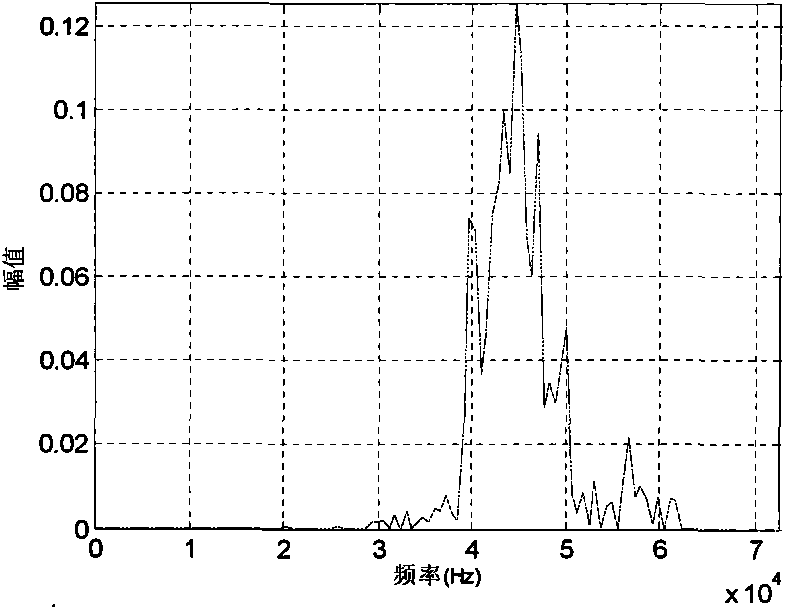

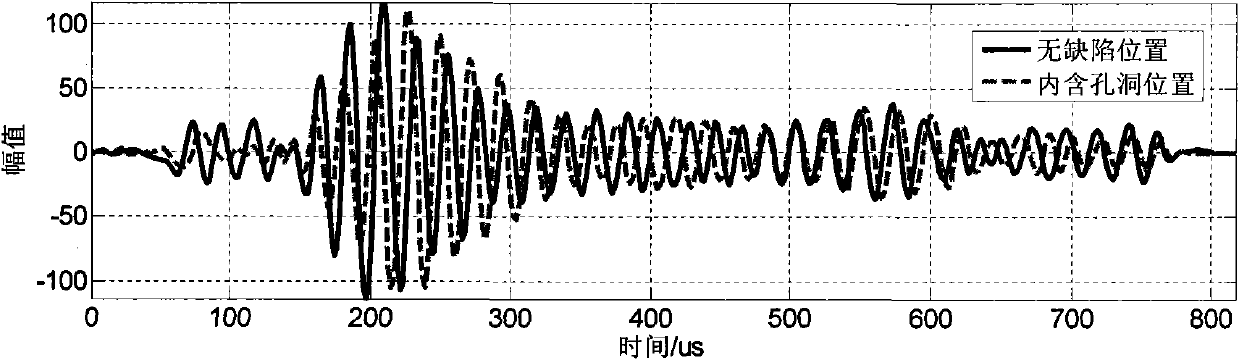

[0082] like Figure 14 As shown, the specific embodiment of the present invention: construct an ultrasonic concrete-filled steel tubular column quality detection system, including an ultrasonic detector for detecting the quality of the concrete-filled steel tubular column, and the ultrasonic generator 2 and ultrasonic receiver 3 of the ultrasonic detector are respectively arranged in the The two ends of the pre-detected concrete-filled steel tubular column 1 also include a filter unit 5 that performs filtering processing on the ultrasonic waves received by the ultrasonic receiver 3, and an HHT conversion unit 6 that performs HHT conversion on the ultrasonic signals filtered by the filter unit 5. , a quality detection unit 7 for detecting the quality of the CFST column 1 according to the ultrasonic signal transformed by the HHT.

[0083] For the specific processing process of the HHT conversion unit 6 of the present invention, see step 300 of the ultrasonic concrete-filled stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com