Throughput type fiber optical tweezers based on coaxial dual-waveguide structure and preparation method

A technology of optical fiber optical tweezers and micro-structured optical fiber, which is applied in the coupling of optical waveguides, multi-layer core/clad optical fibers, clad optical fibers, etc., to achieve the effects of flexible capture, adjustability, and improved practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described in more detail with examples in conjunction with the accompanying drawings:

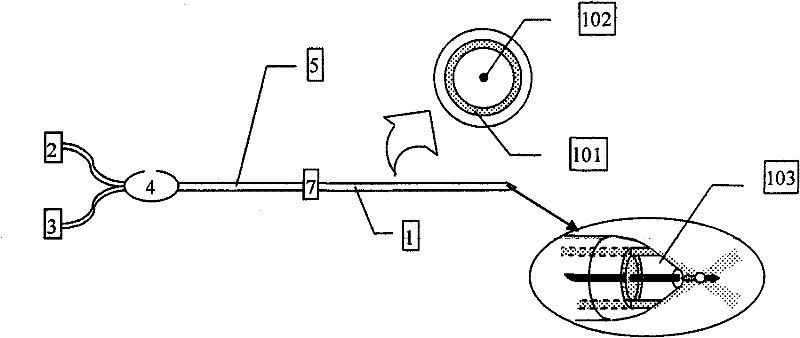

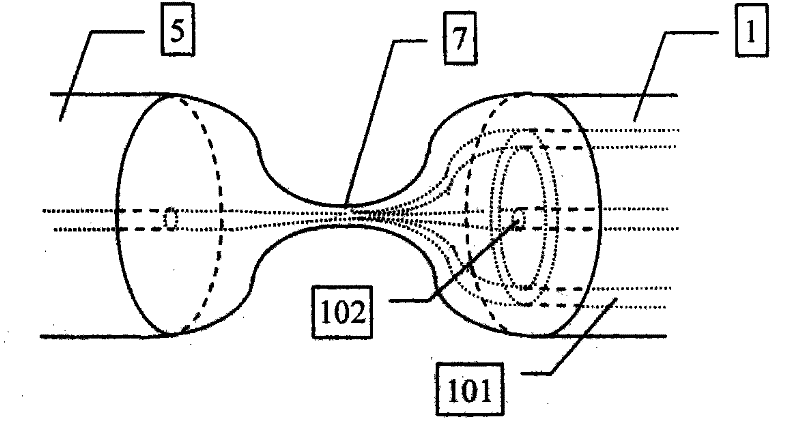

[0024] figure 1 It is a schematic diagram of the system structure of the throughput fiber optical tweezers based on the coaxial dual waveguide microstructure fiber. In the figure, 1 is a coaxial dual waveguide fiber, 101 is a ring core, and 102 is an axial core. The two are distributed concentrically, 2 and 3 are two-wavelength system light sources, 4 is a wavelength division multiplexing device, and 5 is common For the standard single-mode single-core fiber, 7 is the coupling and connection position of the single-core fiber and the coaxial dual-waveguide fiber by fusion and taper, and 103 is the fiber end that is finely polished for capturing small particles.

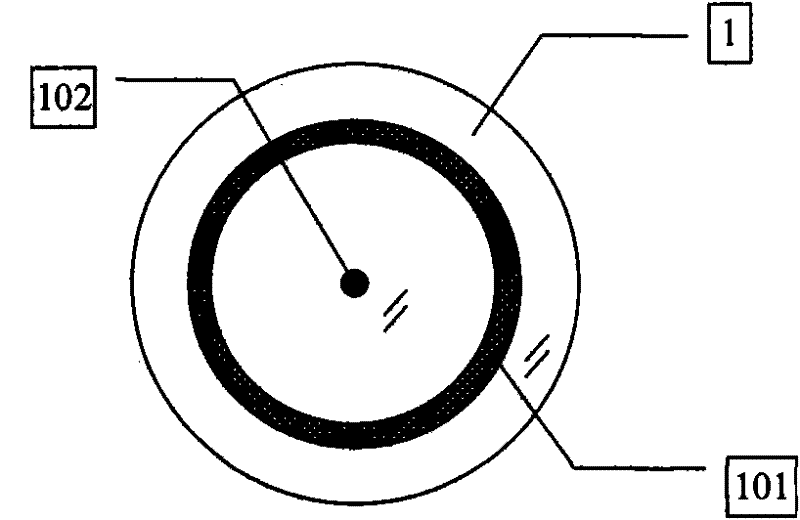

[0025] figure 2 It is a schematic diagram of the cross-sectional structure of a coaxial dual waveguide fiber. In the figure, 1 is a coaxial dual waveguide fiber, 101 is a ring-shaped c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap