Relay contact structure capable of reducing dithering

A technology of relays and contacts, which is applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of jitter, limited vibration reduction effect, increased contact pressure, etc., to achieve improved structure, less jitter, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

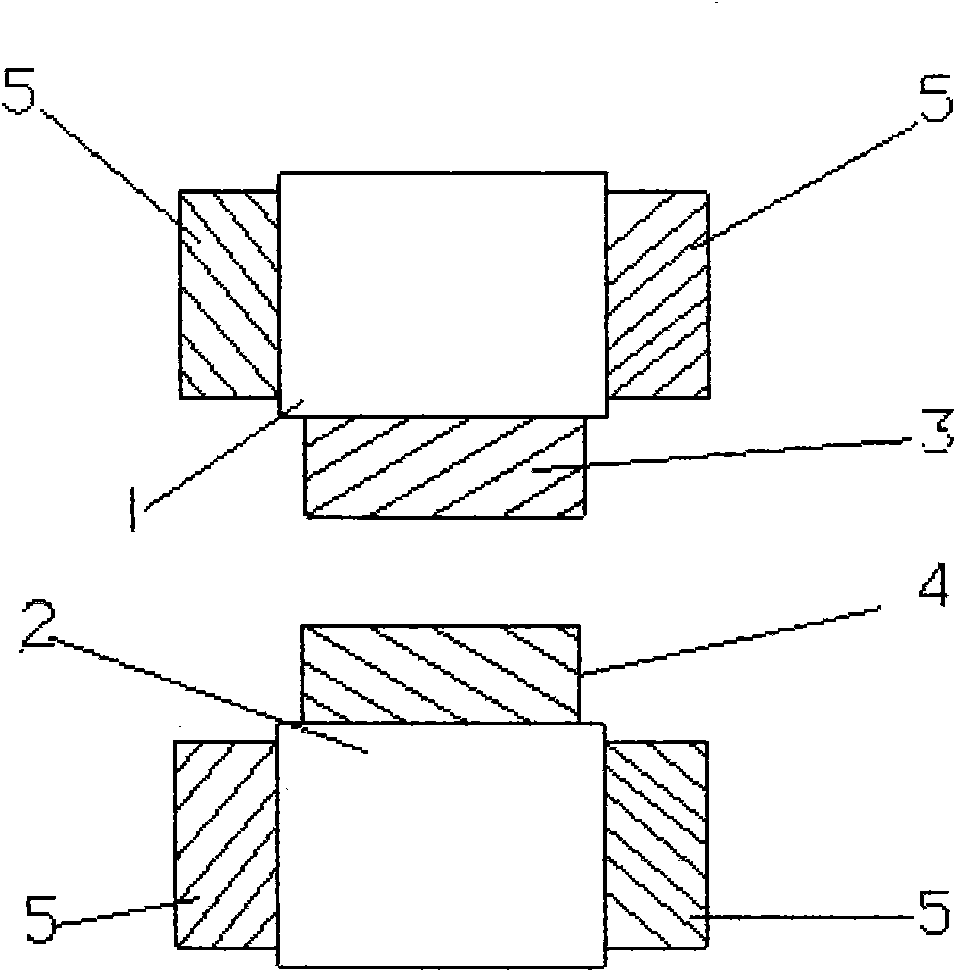

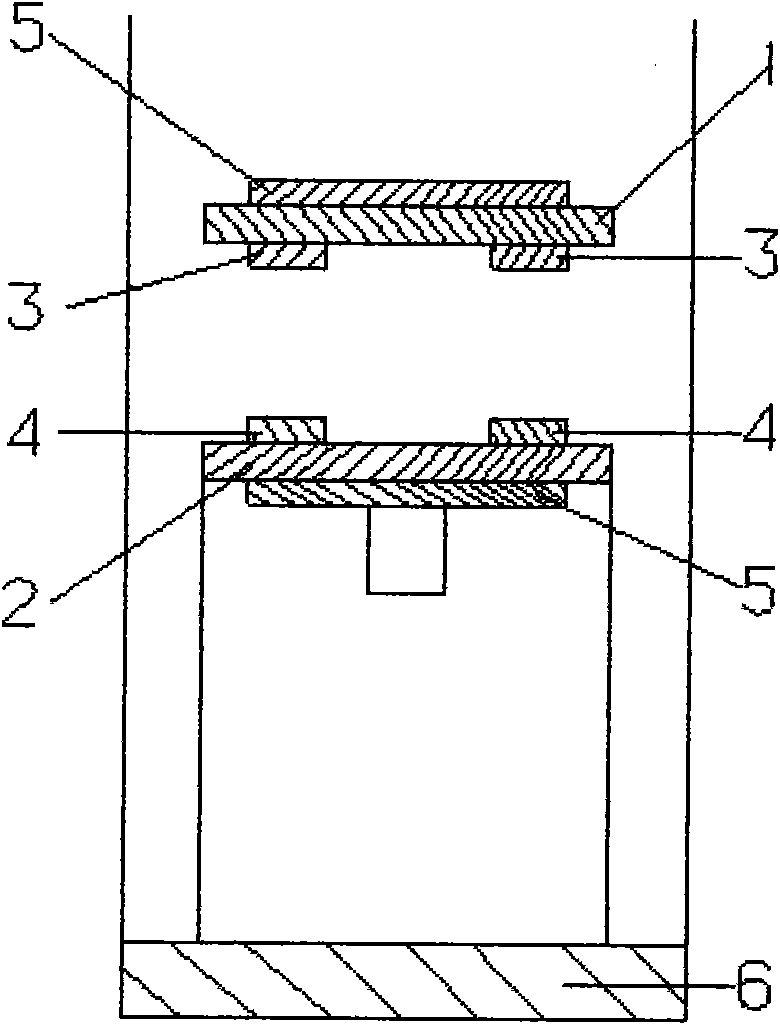

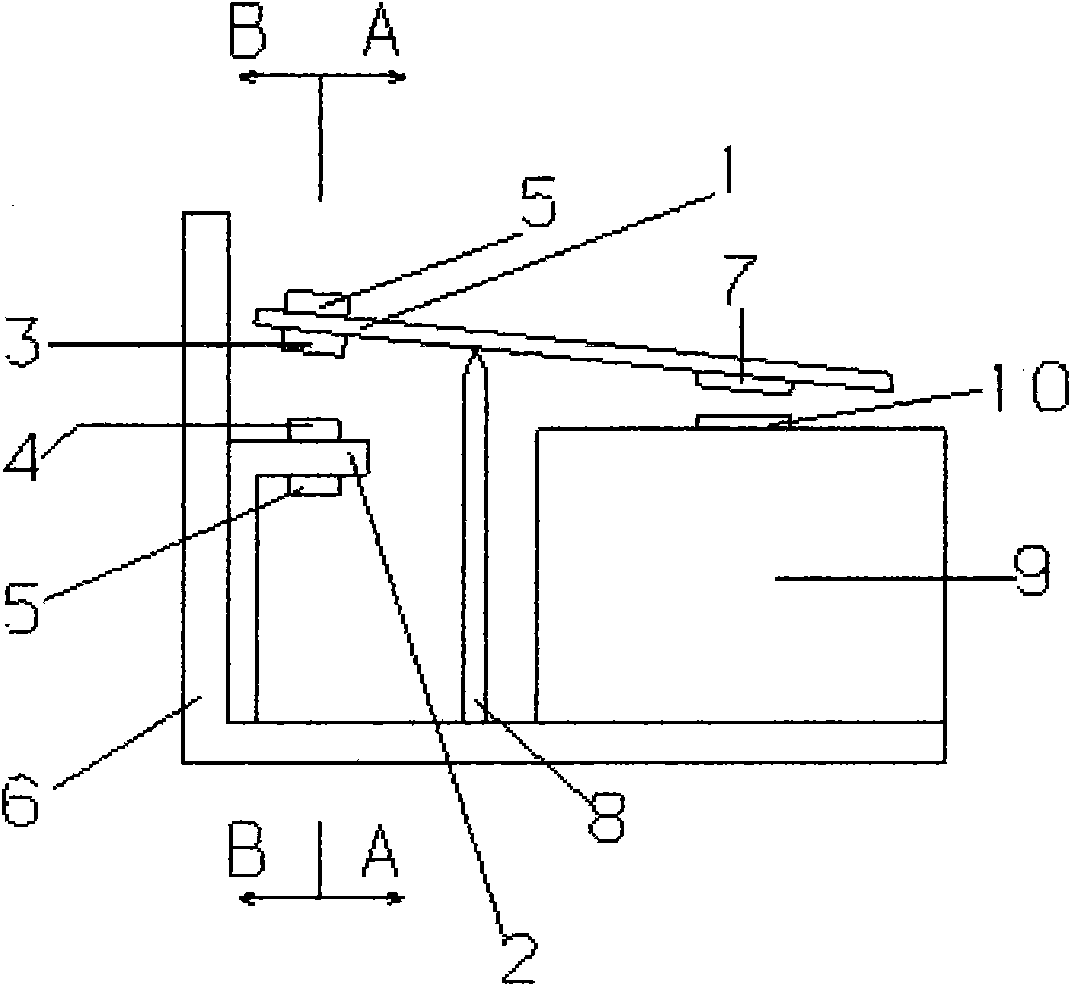

[0015] The electromagnetic relay contact includes a fixed contact piece, a fixed contact fixed on the fixed contact piece, a moving contact piece, and a moving contact fixed on the moving contact piece. The improvement of the present invention is: one or more permanent magnets 5 fixed on the back of the movable contact 3 or rigidly connected to the movable contact piece 1, fixed on the back of the fixed contact 4 or rigidly connected to the fixed contact piece 2 One or more permanent magnets 5.

[0016] attached figure 1 The specific structure of Embodiment 1 of the present invention is provided, referring to the appended figure 1 : two permanent magnets 5 are made cuboid with neodymium-iron-boron permanent magnet material, are bonded to the back side of the moving contact 3 on the moving contact piece 1 and the back side of the static contact 4 on the static contact piece 2. The polarities of the approaching surfaces (facing surfaces) of the two permanent magnets 5 are oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com