Pressure plate assembly, particularly for a friction clutch having automatic wear compensation

A friction clutch and wear compensation technology, which is applied in friction clutches, clutches, mechanically driven clutches, etc., can solve problems such as inaccuracy and wear, and achieve the effect of zero point adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

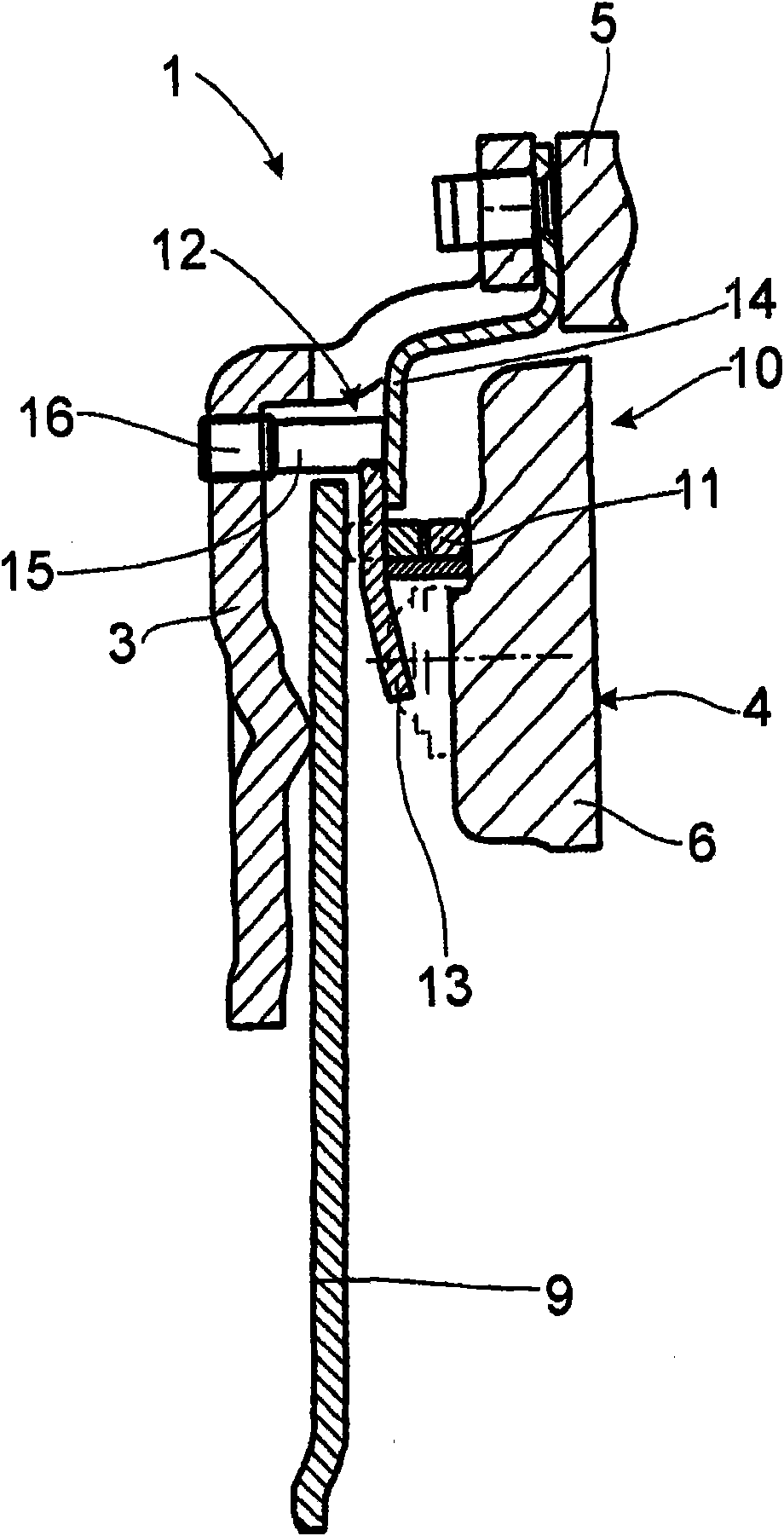

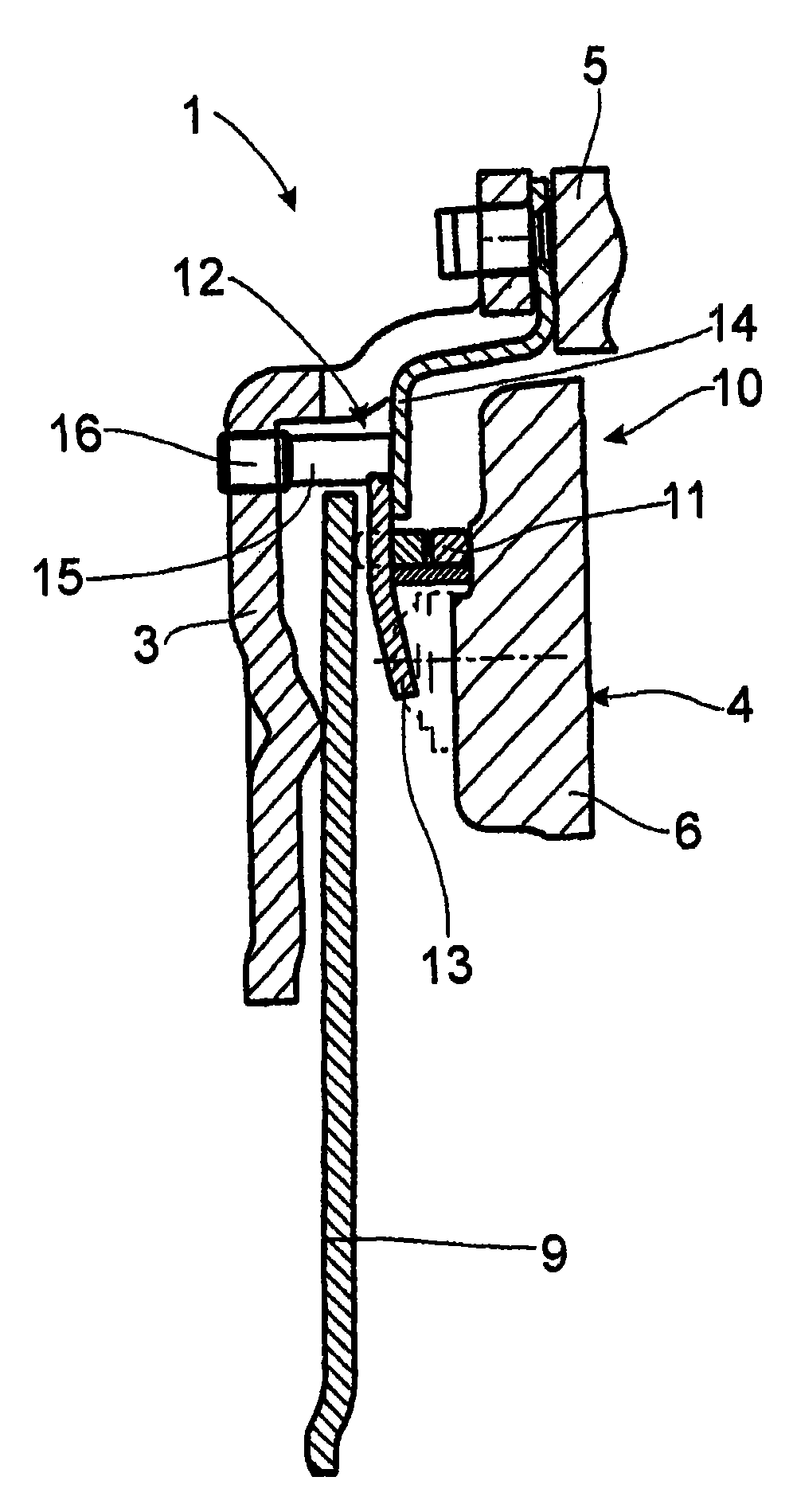

[0036] exist figure 1The pressure plate assembly 1 designed according to the invention shown in , is provided with a housing part 3 which is connected to a mating housing part 5 . A pressure plate 6 with one of the two counter-friction surfaces 4 is inserted in the housing part 3 in a rotationally fixed manner relative to the housing part 3 , but axially displaceable. Furthermore, a force accumulator 9 in the form of a diaphragm spring is arranged on the housing part 3 for applying a pressing force to the pressure plate 6 . However, it is also possible to provide the force store 9 as a lever element which transmits the pressing force generated outside the pressure plate assembly 1 to the force store 9 via the clutch actuation system. Such an embodiment is generally referred to in the prior art as a "normally-open-clutch'", ie a clutch of the normally open type. A wear readjustment device 10 is formed on the pressure plate 6 and has at least one readjustment element 11 for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com