Apparatus and method for taking safety measures in power tools

A technology for electric tools and safety measures, applied in the field of devices and methods for taking safety measures in electric tools, can solve the problems of inflexible application of different use environments, high cost, limited evaluation speed, etc., to reduce possible performance, improved safety, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Electronic components are used in modern electrical equipment or power tools for regulation, power boosting, protective functions or additional functions. The electronic components in modern power tools are therefore often equipped with microcontrollers, by means of which these functions are carried out.

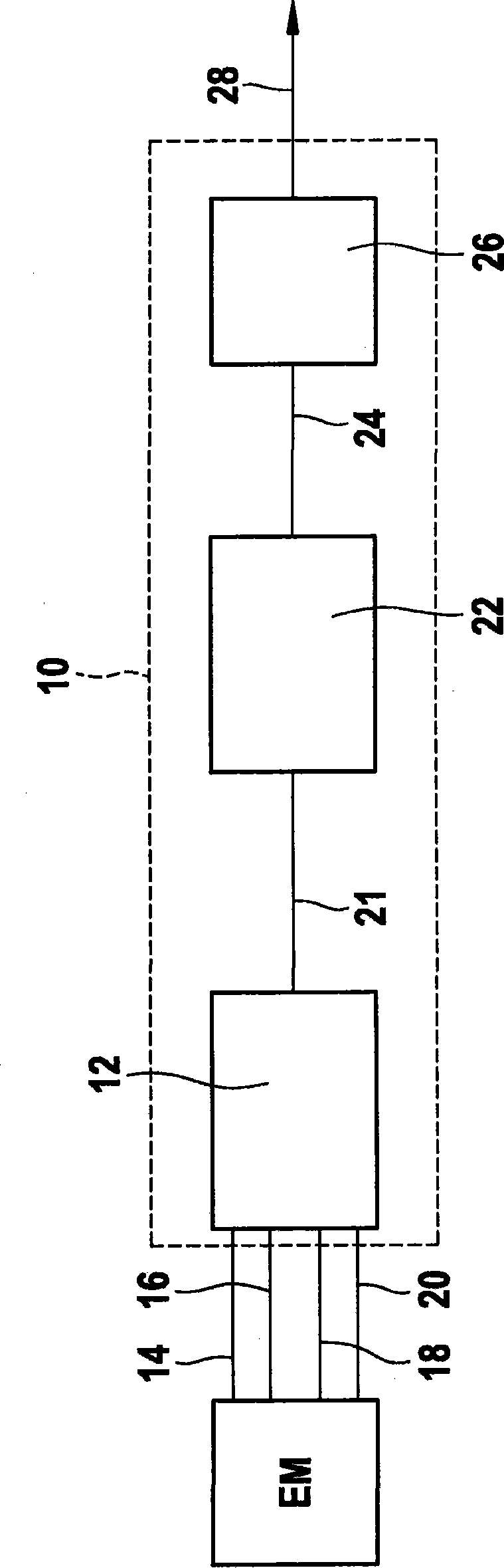

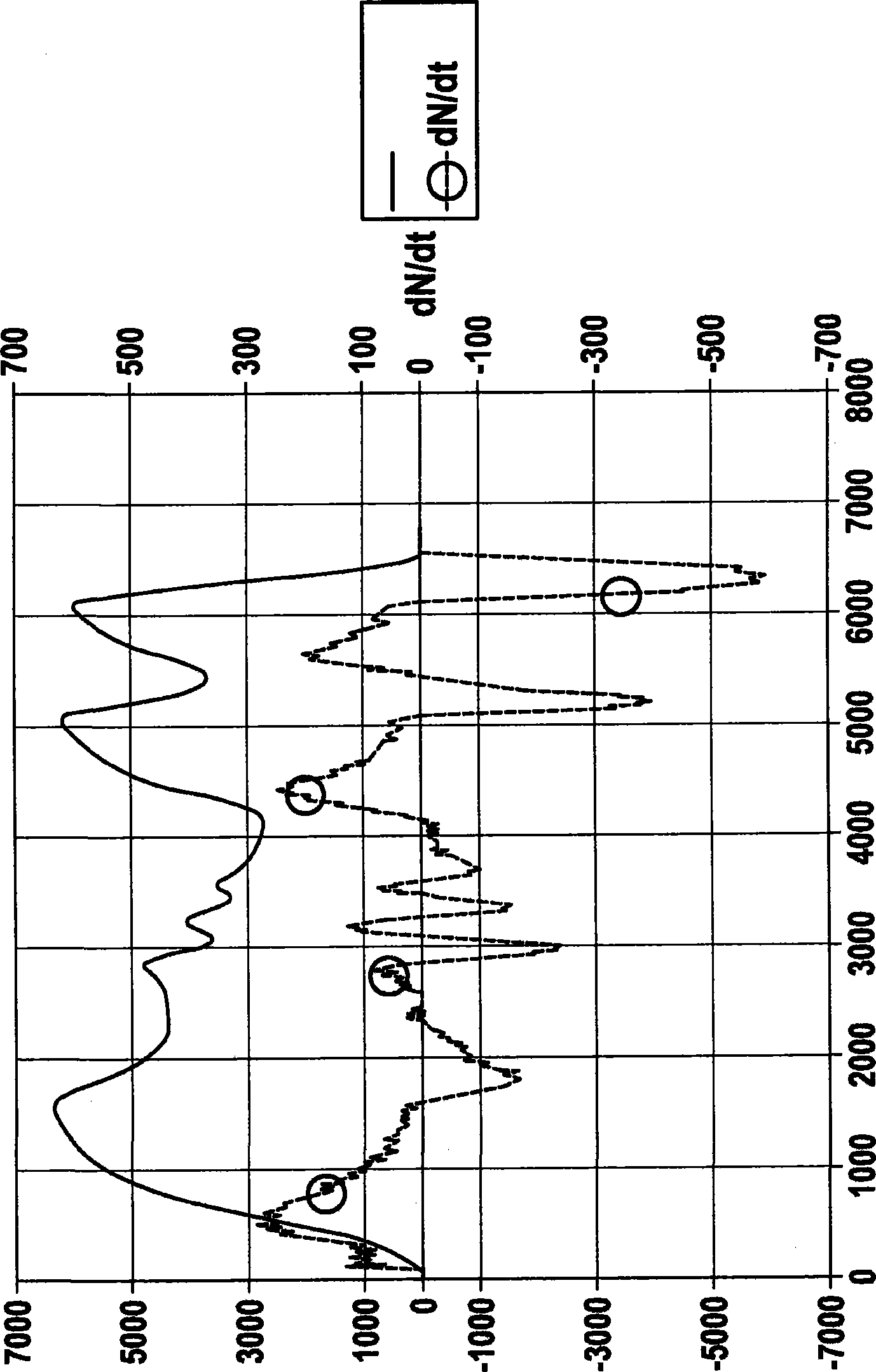

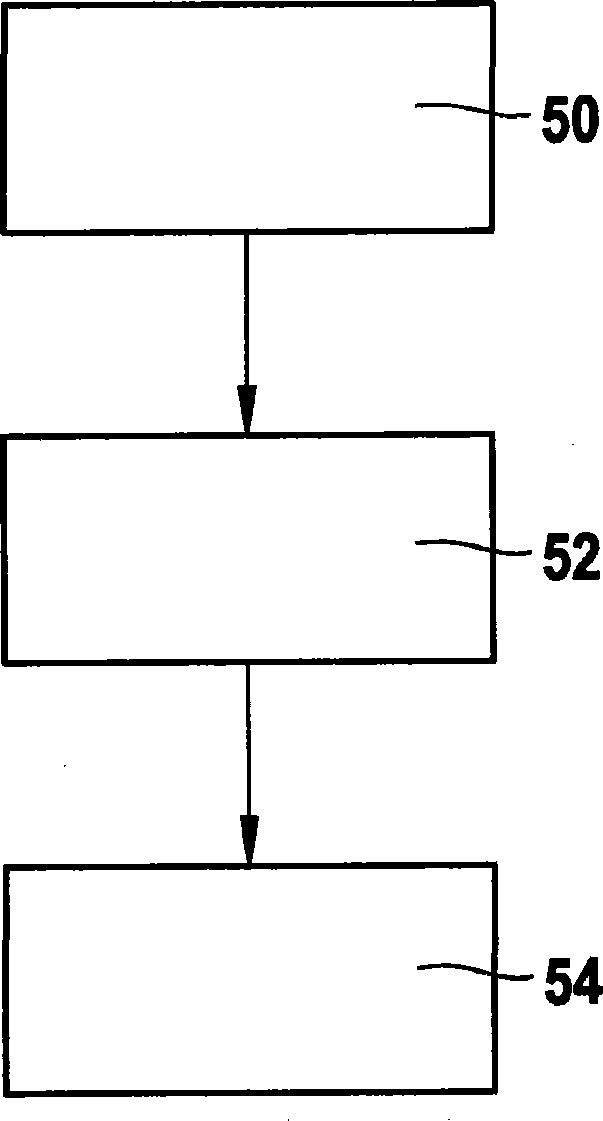

[0029] The solutions presented here describe on the one hand a protective function for an electric tool, electric machine tool or electric device, and on the other hand a protective function for the user. The equipment to be protected, such as an electric tool, electric machine tool or electric equipment, is hereinafter simply referred to as "electric equipment". In the solution presented here, a signal is generated from one or more motor parameters such as motor current, armature voltage or the like, which is proportional to the rotational speed or the load of the machine or electric system. A derivative, for example, is formed from a signal proportional to the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com