Ferris wheel

A ferris wheel and turntable technology, which is applied to large runners, Russian swings, entertainment, etc., can solve the problems of difficult machining of bearing installation position accuracy, high requirements for the coaxiality of the rotating shaft, and complicated installation process of the rotating shaft, achieving simple installation and Convenience, reduced process requirements and processing difficulty, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

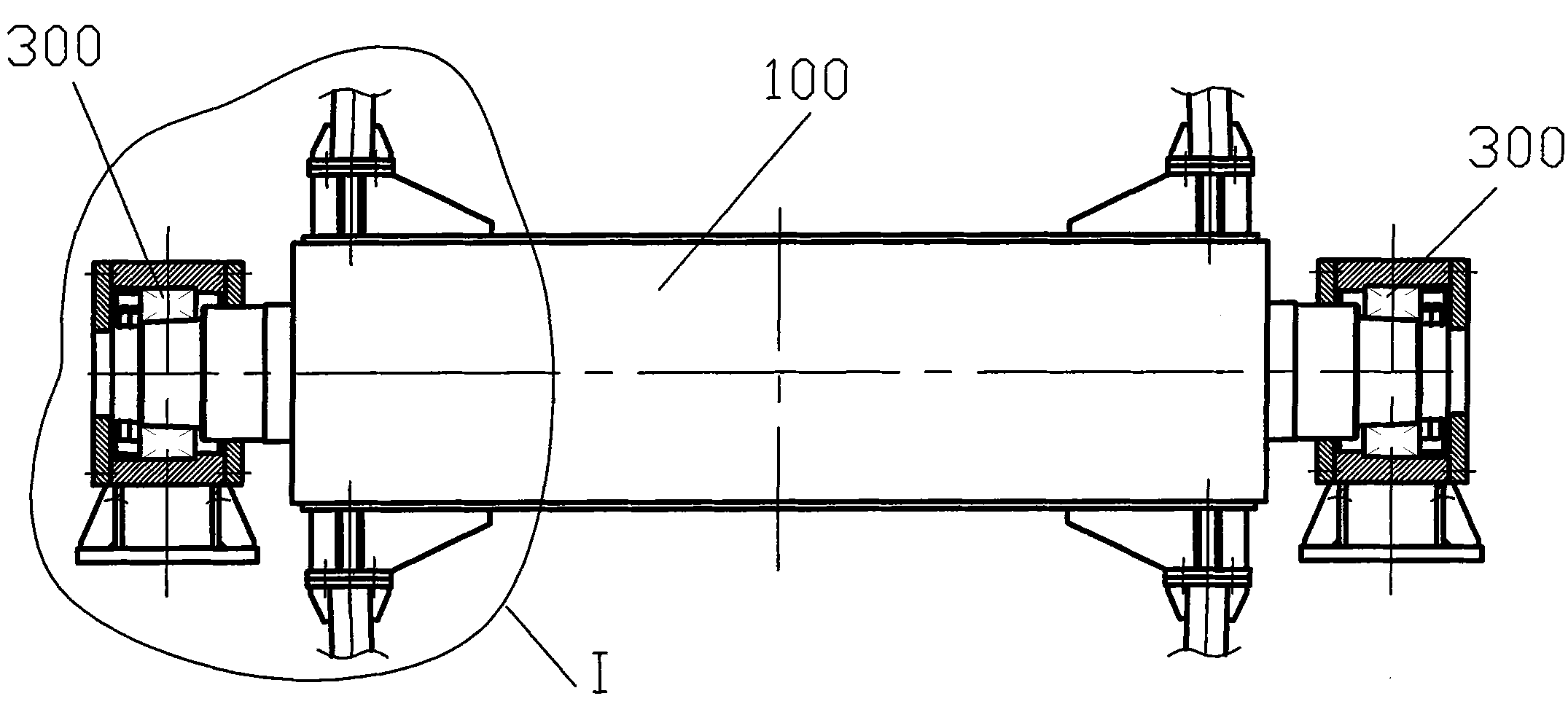

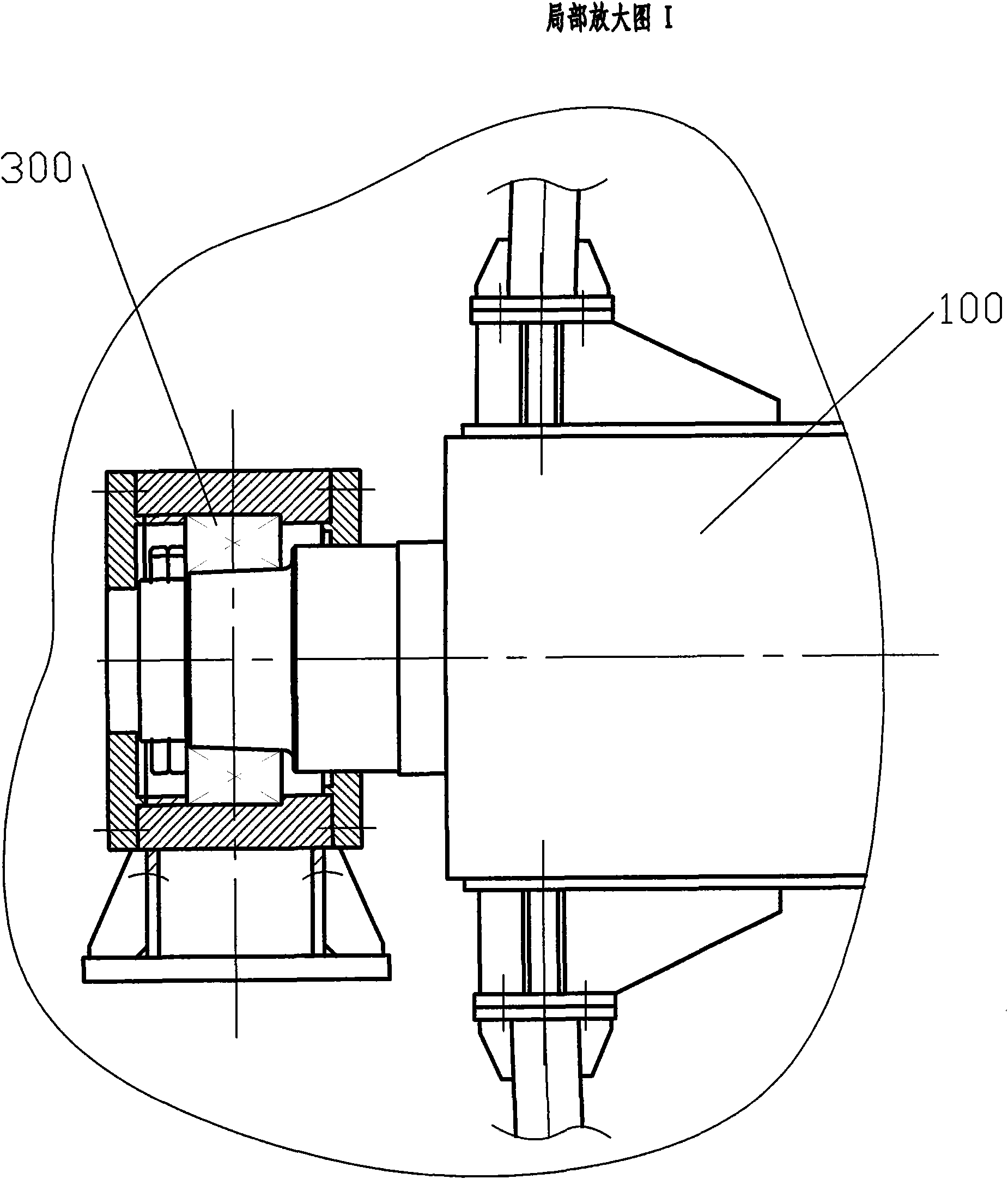

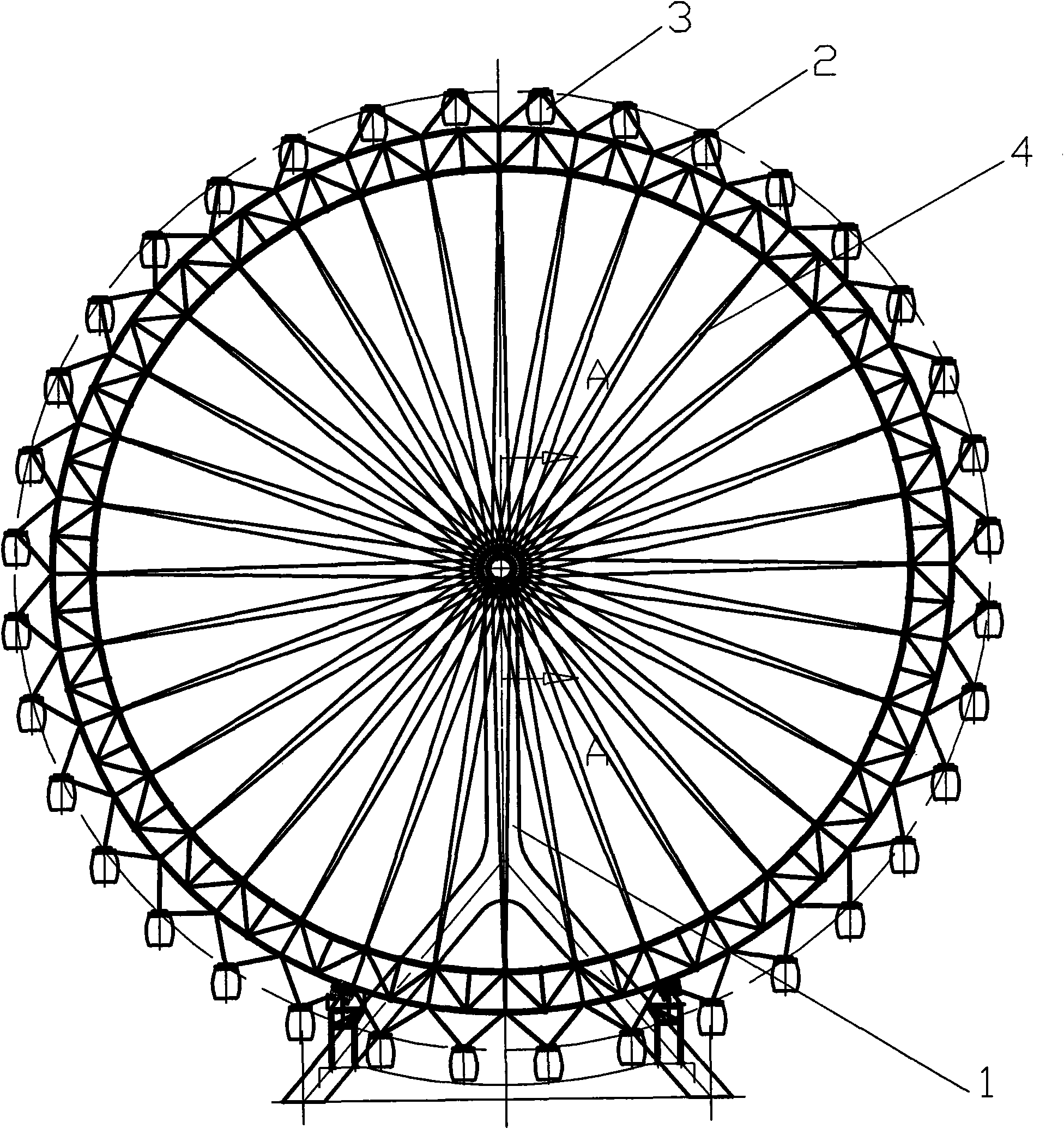

[0016] The present invention is a kind of Ferris wheel, comprises Ferris wheel bracket 1, hollow circular turntable 2, many cockpits 3 that ring cloth outside the turntable and several traction steel cables 4 that connect turntable, above the support by two ends stigma 11 each Install the slewing support 6 and connect it with the middle beam 5 as a whole as the center of the turntable. The outer ring 62 of the slewing support 6 is equipped with a cable tray 7, and the two ends of all the traction cables 4 are respectively connected with the cable tray 7 and the turntable 2. , the turntable 2 forms a coaxial synchronous rotation with the cable tray 7 after being pulled by the spoke-type distribution cables. When working, under the action of the Ferris wheel driving mechanism (not shown in the figure), the friction turntable 2 of the driving wheel drives the cabin 3, the cable tray 7 and the outer ring 62 of the slewing support to rotate around the beam 5, realizing the 360-degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com