Rolling mill roll box type stage cooling device

A technology of segment cooling and rolling, applied in the direction of rolling, metal rolling, metal rolling, etc., to achieve the effect of good shape and reduce rolling requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

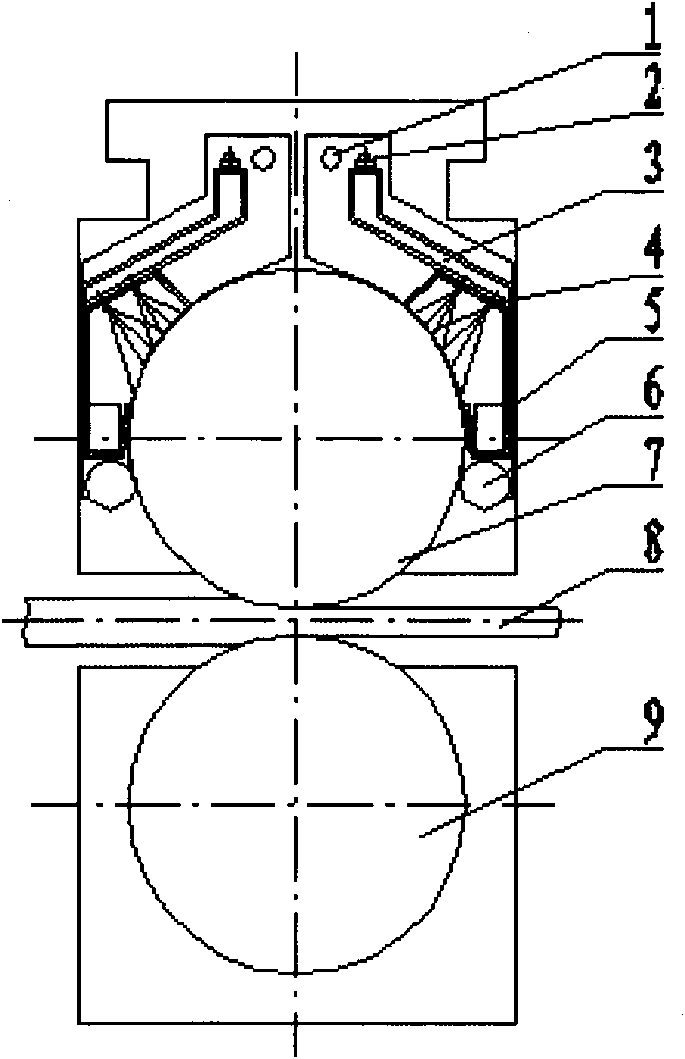

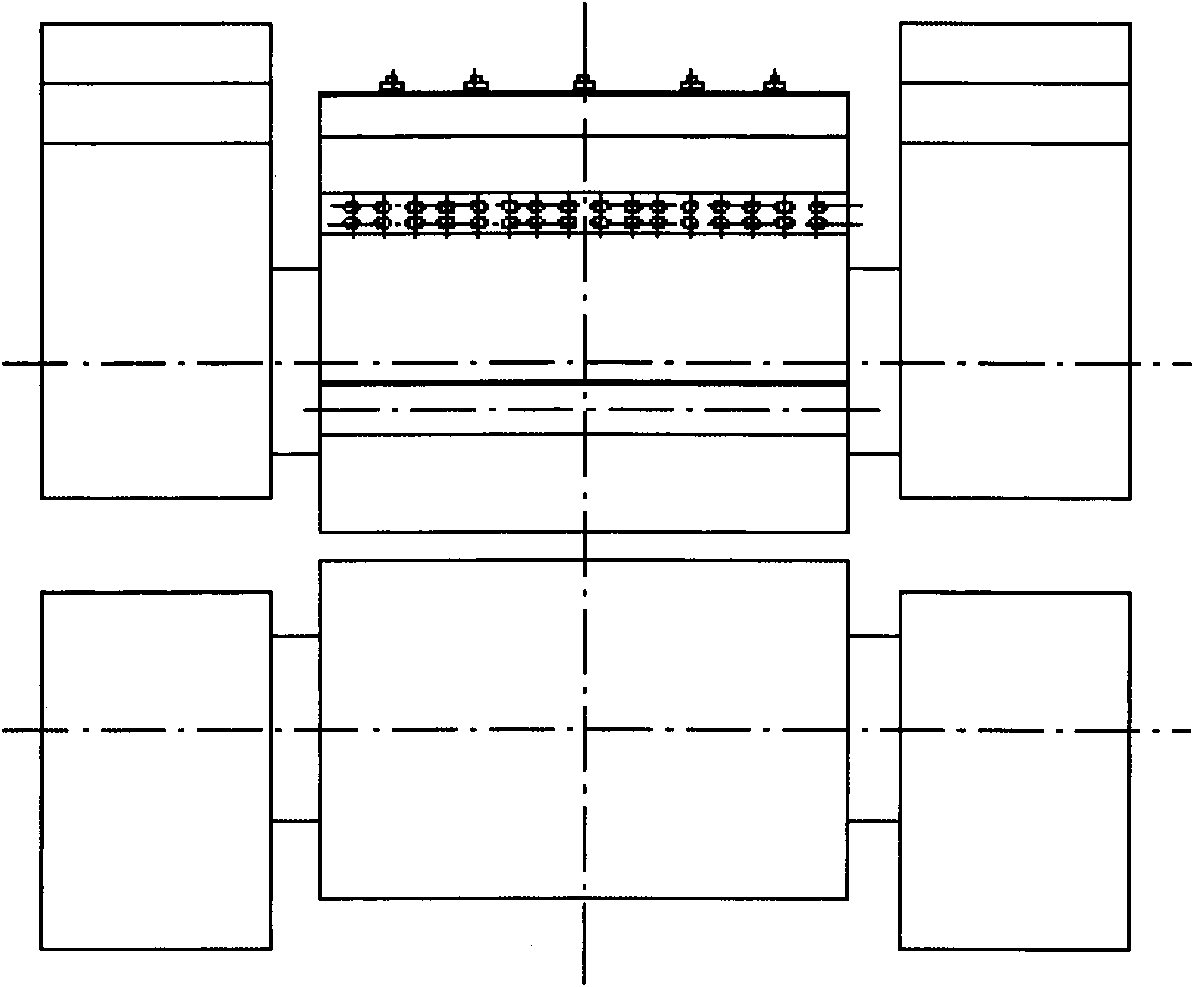

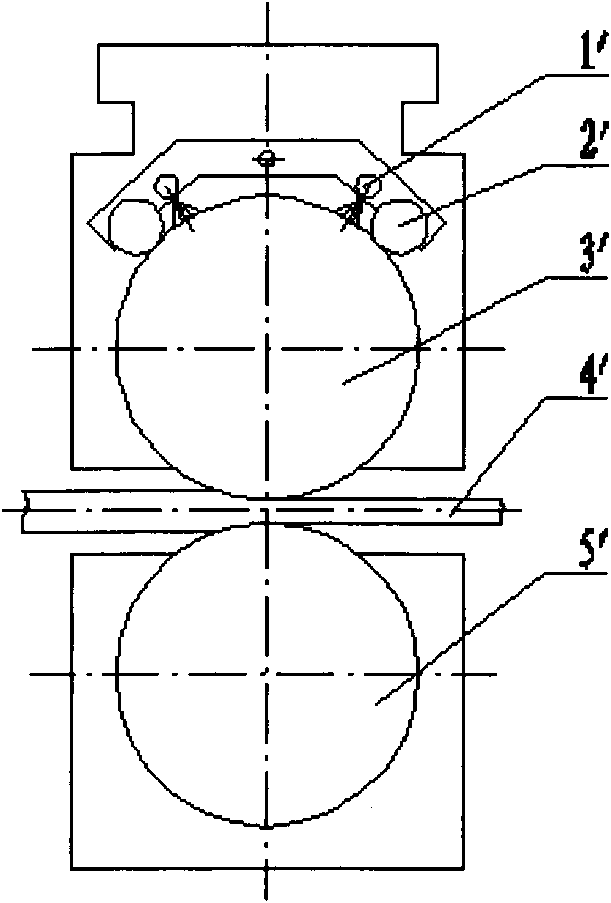

[0016] like figure 1 , 2 The box-type subsection cooling device for rolling mill roll shown in and 4 is mainly composed of a rotary shaft 1, a quick-change joint 2, a subsection water supply box 3, a nozzle 4, a collection box 5 and a pressure roller 6 and the like.

[0017] The device is connected to the roll bearing housings on both sides through the rotary shaft 1, and the external supply system of the coolant is connected to the quick-change joint 2, which supplies the coolant to the segmented water supply box 3, and the nozzle 4 is installed in the segmented water supply box 3, the coolant sprayed by the nozzle 4 on the surface of the upper work roll is recovered by the collection box 5 in the first stage, and flows to both sides of the roll through the holes on both sides, and the coolant overflowing between the collection box 5 and the upper work roll 7 passes through The lamination of the press roll 6 and the upper work roll 7 realizes the second-stage recovery, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com