Clamp for butt welding

A technology of butt welding and fixtures, which is applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., and can solve problems such as inconvenient use, high equipment cost, and no heat dissipation device for fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

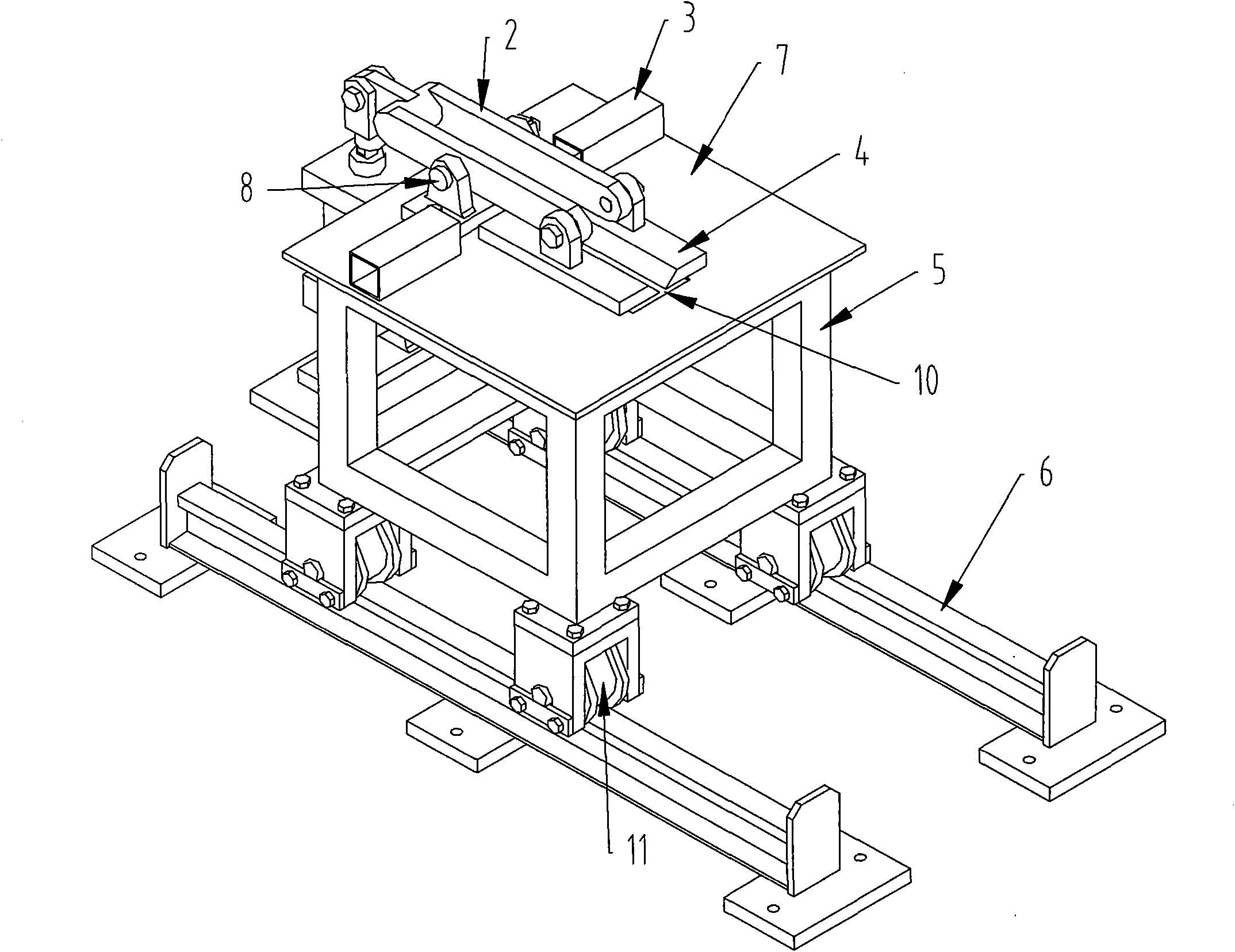

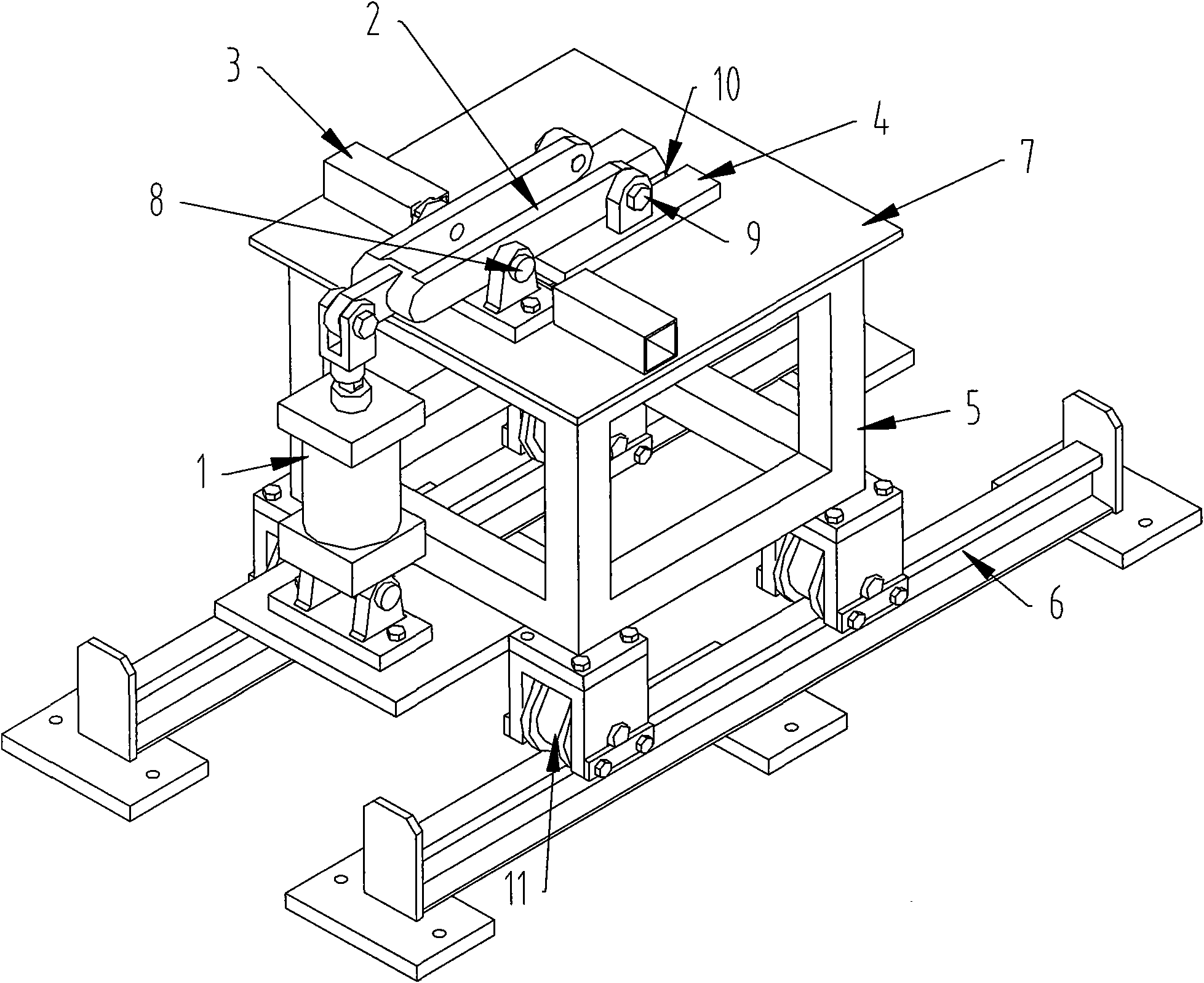

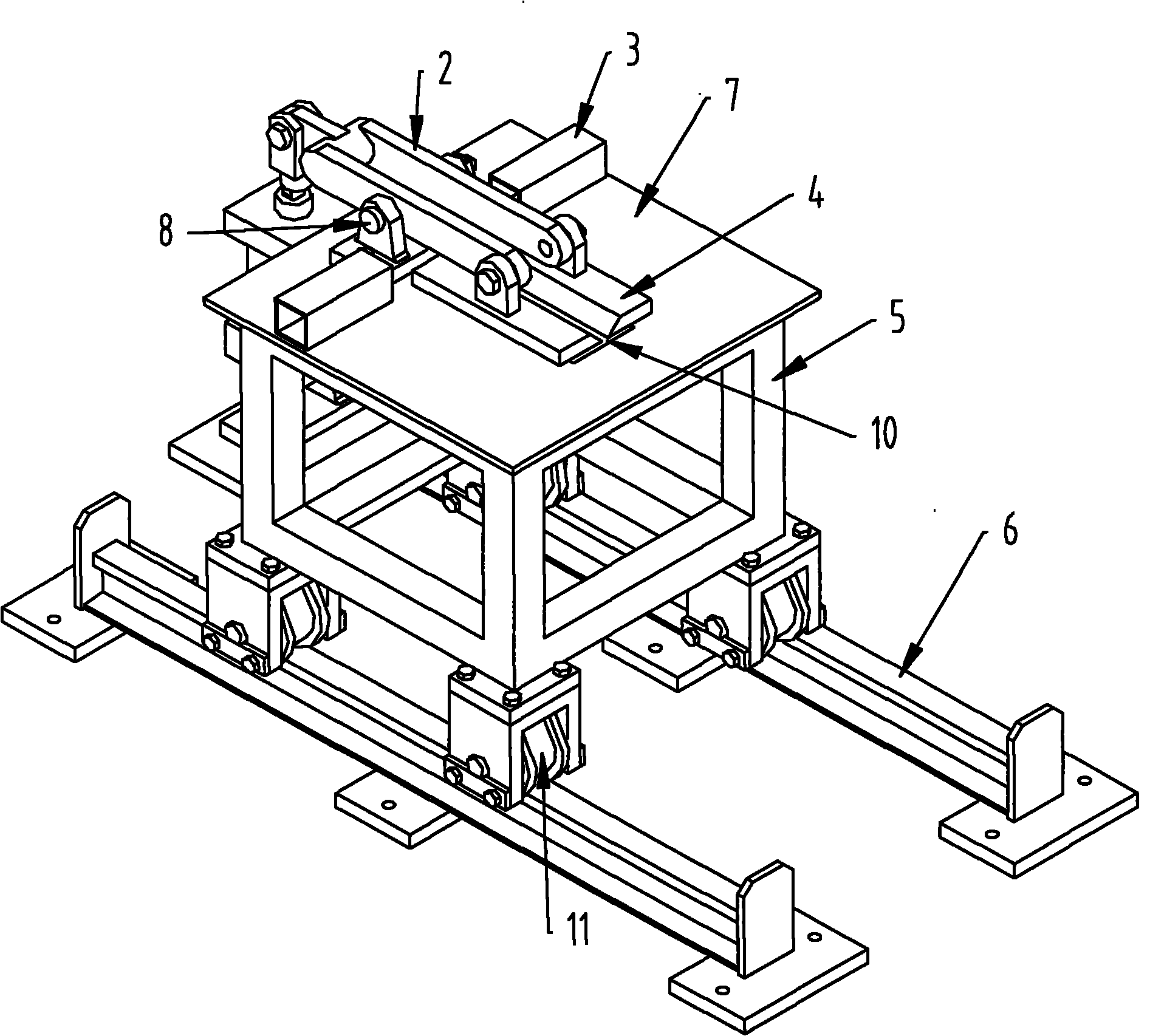

[0012] figure 1 , 2 The shown clamp for butt welding includes a cylinder 1 , a pressing arm 2 , a sheet positioning block 3 , two pressing plates 4 , a bracket 5 , and a slide rail 6 . The top of the support 5 is a platen 7, and the bottom of the support 5 is slidably arranged on the slide rail by rollers 11. The pressing arm is hinged on the bracket through the shaft 8 near the middle part; the two pressing plates 4 are hinged at the front end of the pressing arm through the shaft 9; the rear end of the pressing arm is hinged with the piston rod of the cylinder 1. The cylinder block of cylinder 1 is connected on the bracket 5 . A copper plate 10 is inlaid on the platen opposite to the pressing plate; a copper strip is arranged at the bottom of the pressing plate.

[0013] Pushing and pulling up and down the cylinder 1, the pressing arm 2 swings around the axis 8, and the pressing plate 4 installed on the pressing arm 2 also moves up and down, thereby pressing the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com