Method for preventing hitch of hydraulic support from being filled by crushed gangue

A technology of hydraulic supports and column sockets, which is applied in mine roof supports, earth square drilling, mining equipment, etc., can solve problems affecting the movement of column 1, complex internal dimensions, and obstruction of lifting frames, so as to shorten the time for column replacement and facilitate construction. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The polyurethane foam filling principle of the present invention is that the polymerization reaction of polyether isocyanate can generate urethane, that is, the required polyurethane can be generated, that is, polyurethane foam. Add catalyst (such as dibutyltin dilaurate or triethylenediamine or triethanolamine), crosslinking agent (such as ethylenediamine polyether), foaming agent (such as R-113 or R-11 and water) ), foam stabilizer (such as silicone oil), can adjust the tensile strength P and tensile elongation at break δ of foamed plastics to meet the process requirements.

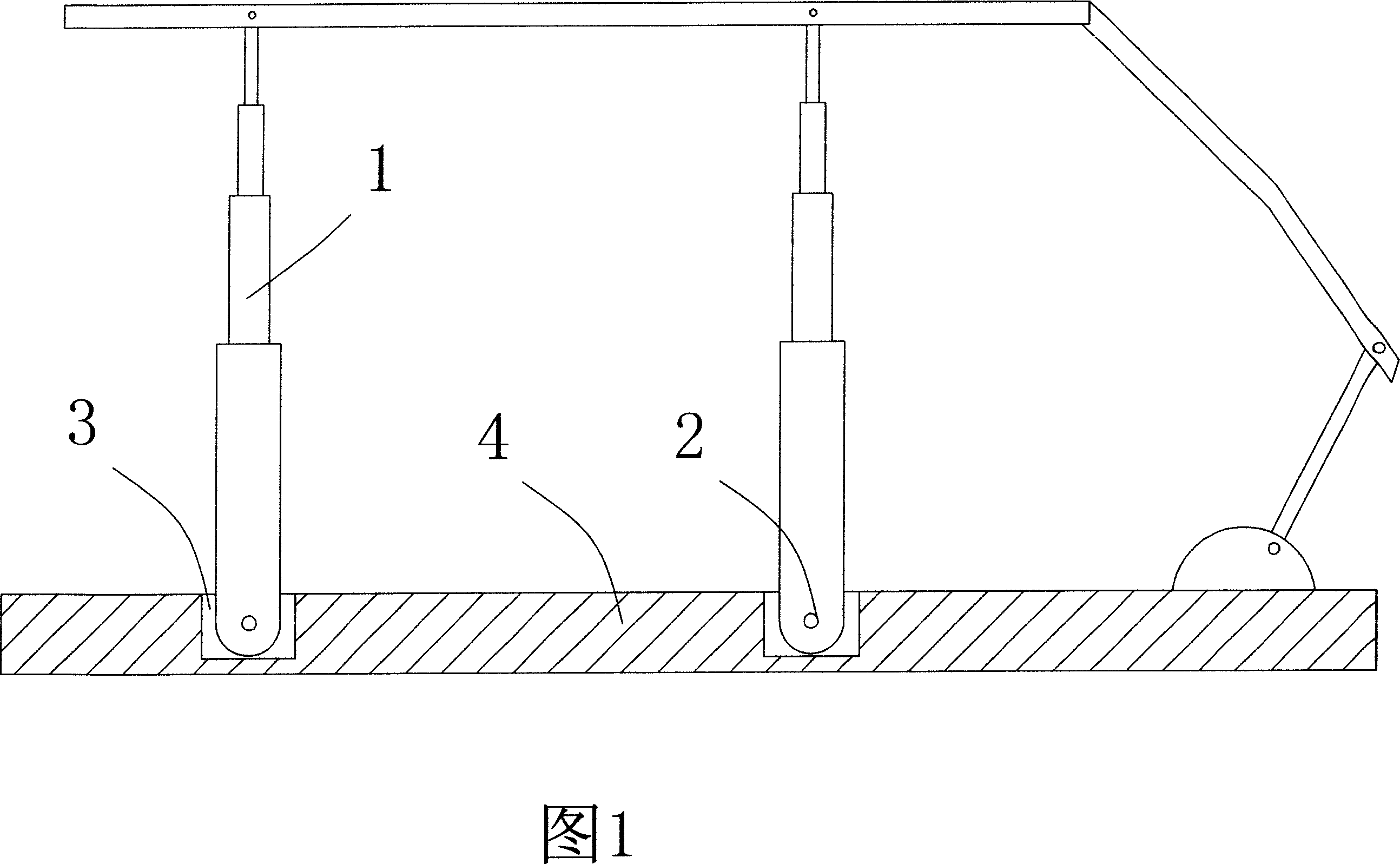

[0009] As shown in Fig. 1, the present invention is specifically that the modified polyurethane material is constructed on-site, directly sprayed into the column socket 3 of the hydraulic support through high pressure, and foamed to have a certain tensile strength P and a tensile breaking elongation. Filler with a length δ, so as to seal the column socket 3. Tensile strength and elongation can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com