Round screw-arris plastic extruder screw

A technology of screw and flight, which is applied in the field of round flight plastic extruder screws, can solve the problems of inability to separate solids and melts in time, low production efficiency, slow plasticization speed, etc., achieve small resistance, short conveying distance, Reduces the effects of excessive temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

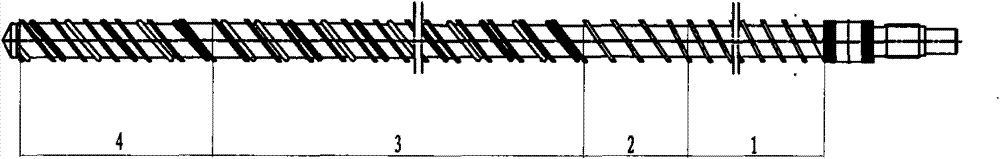

[0012] refer to figure 1 , figure 2 , image 3 , The screw of the plastic extruder is composed of a conveying section 1, a transition section 2, a first compression section 3, and a second compression section 4.

[0013] The length of the conveying section 1 is 27% of the effective length of the screw, the length of the transition section 2 is 7% of the effective length of the screw, the length of the first compression section 3 is 50% of the effective length of the screw, and the length of the second compression section 4 is the length of the screw 16% of the effective length.

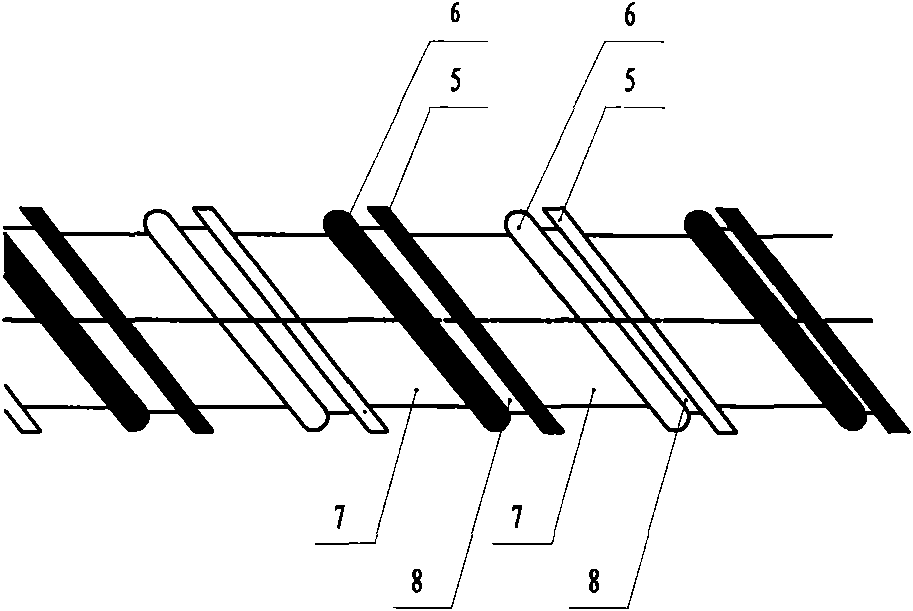

[0014] The plastic is added by the hopper and conveyed forward under the thrust of the screw flight. After being compacted and preheated in the conveying section 1 and the transition section 2, it enters the first compression section 3. In the first compression section 3, there are two main threads 5 (distinguished by black and white in the figure) and two auxiliary threads 6 (distinguished by bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com