Full-automatic exhaust coal pellet-forming machine

A fully automatic and egg machine technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problem that the briquette gas cannot be fully discharged outside the briquette body, and achieve high economic value and social value, high production efficiency, and the effect of saving coal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

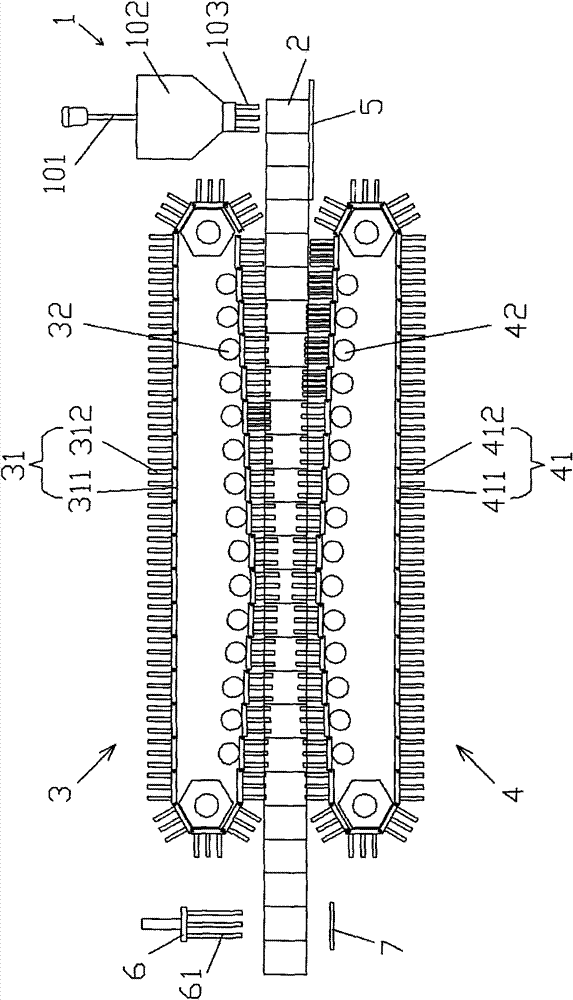

[0030] Example: see Figure 1~5 As shown, the fully automatic exhaust briquette egg forming machine includes an upper hopper 1, which is composed of an upper hopper 1, a forming die chain 2, an upper extrusion die chain 3, a lower extrusion die chain 4 and a baffle plate 5 ;

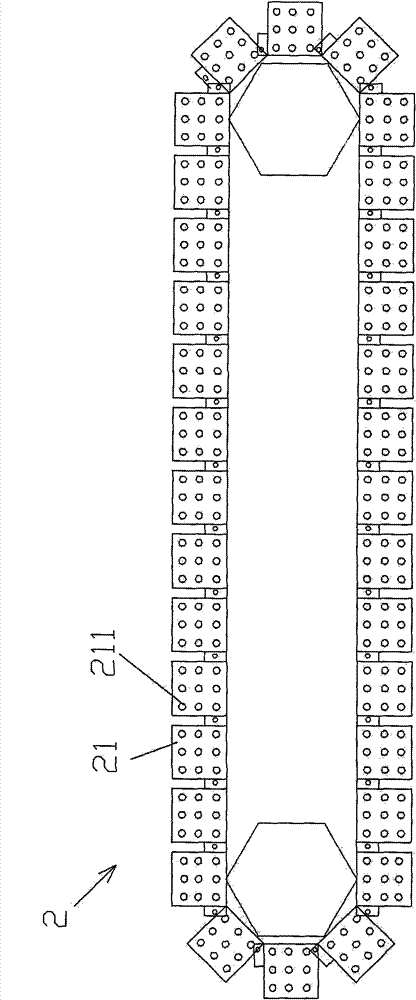

[0031] The structure of the forming die chain 2 is that several forming dies 21 hinged together form an endless belt shape, and the hexagonal pulley drives several forming dies 21 hinged together to rotate, and a through hole 211 is formed on the forming die 21;

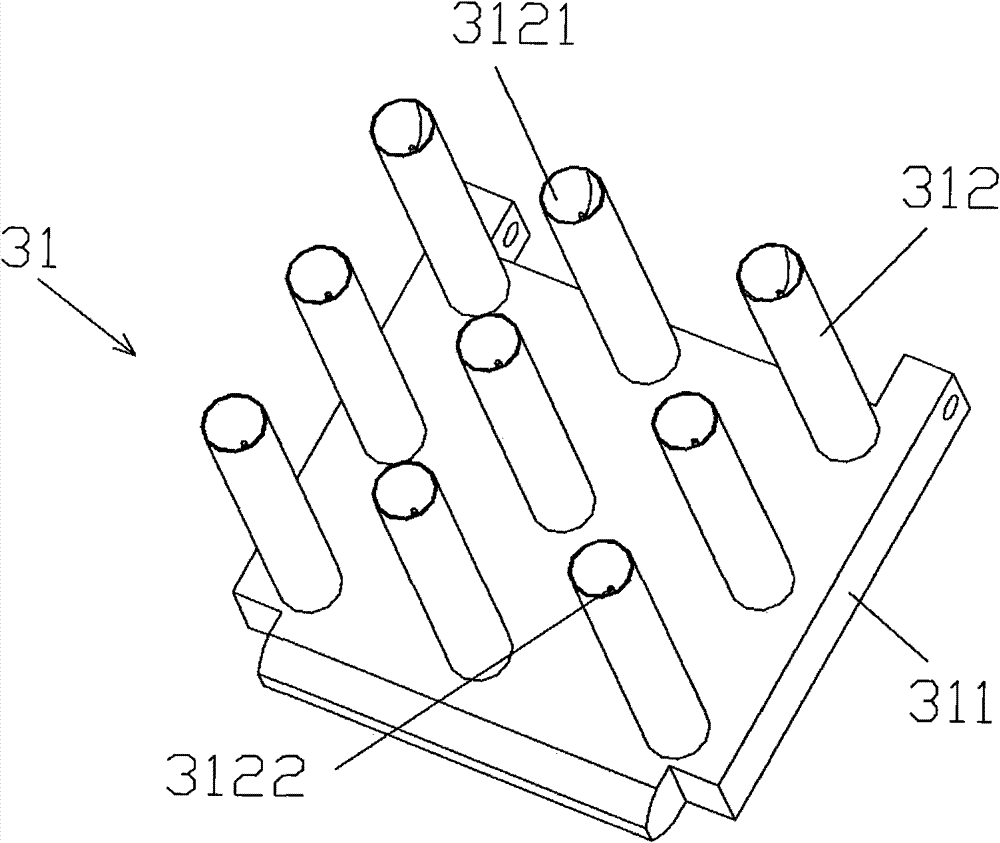

[0032] The structure of the upper extruding die chain 3 is that several upper extruding dies 31 hinged together form an annular belt shape, and the hexagonal pulley drives several upper extruding dies 31 hinged together to rotate, and the upper extruding dies 31 rotate. The pressing die 31 is composed of a vertically fixed upper extruding column 312 on the upper template 311, and the upper positioning roller 32 resists the rear portion of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com