Dried noodle packager and flour finishing device thereof

A technology of hanging bread and wrapping, which is applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., and can solve the problems of messy noodles, broken, heavy labor, not compact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

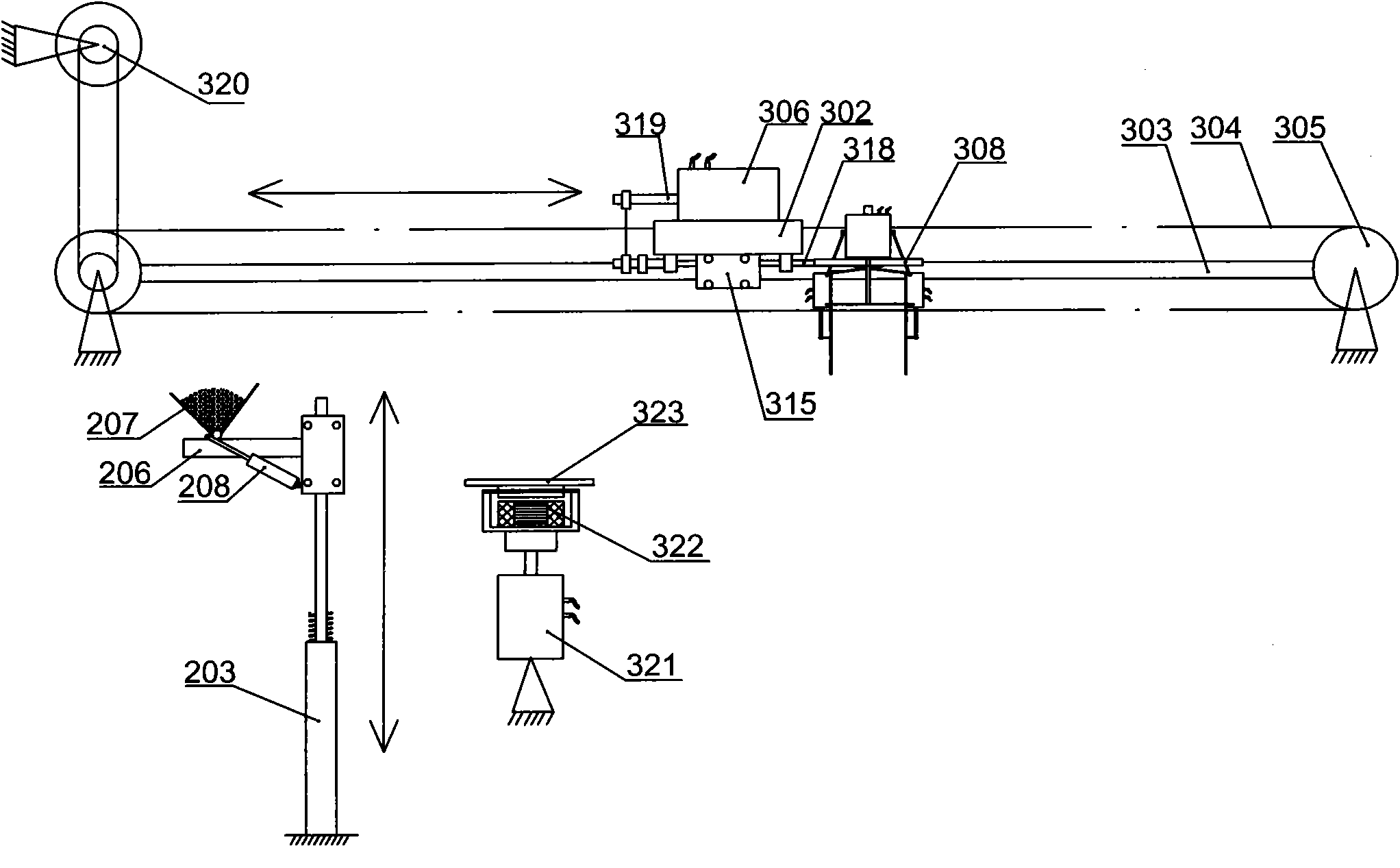

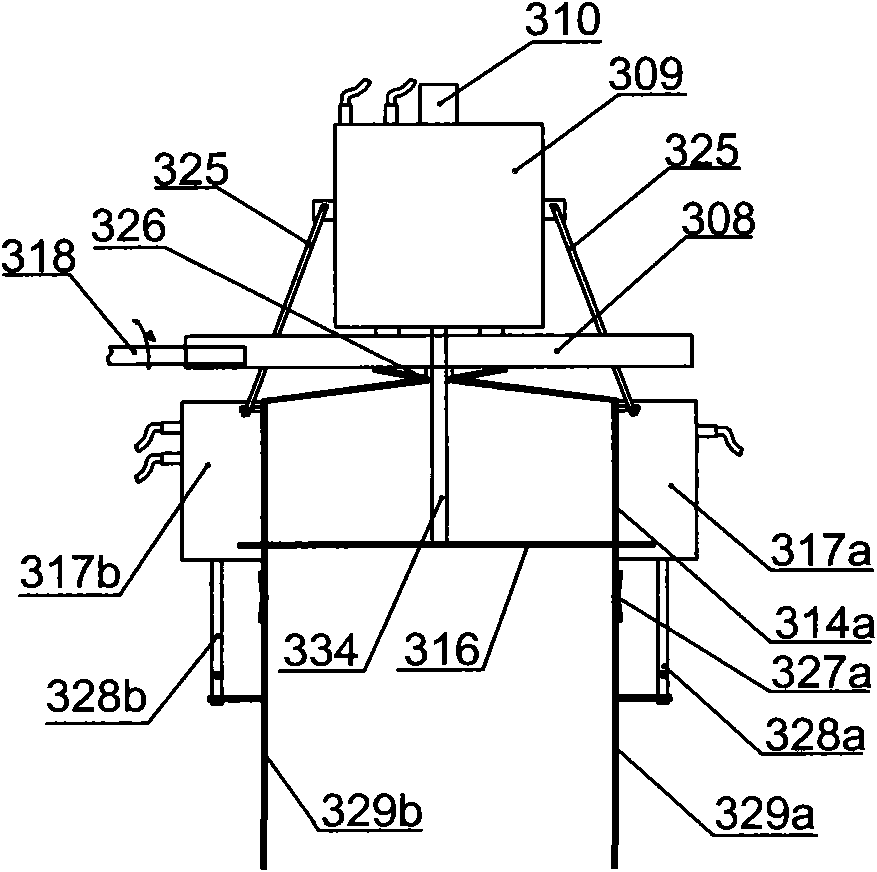

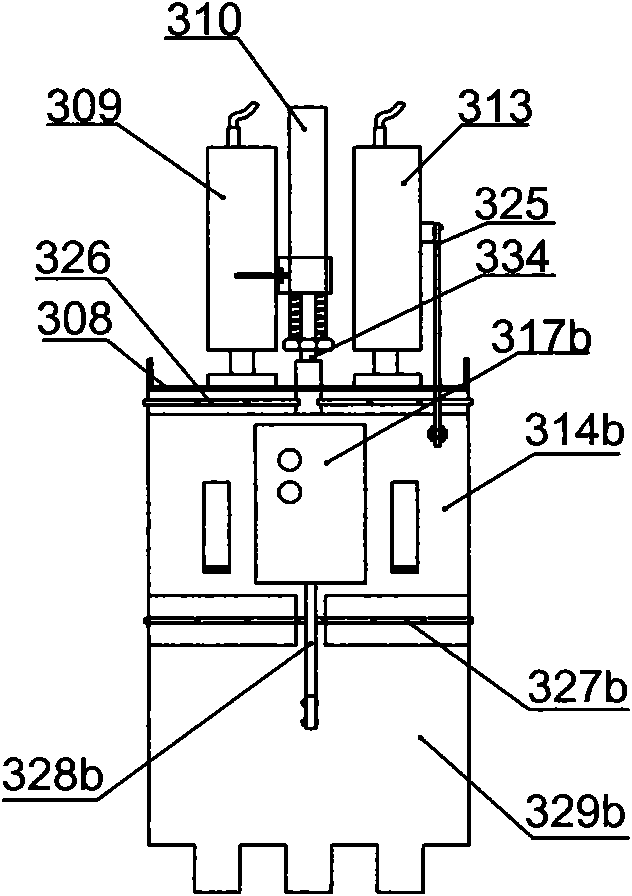

[0070] Embodiment one: see figure 1 , diagram 2-1 , Figure 2-2 , Figure 3-1 , Figure 3-2 , Figure 3-3 , Figure 4 , a whole surface device of a dried noodle packaging machine, comprising a fixed bracket 301, a sliding guide rail 303, a synchronous wheel 305 and a synchronous belt 304 located on the two opposite inner sides of the fixed bracket 301, and the sliding guide rails 303 on both sides are matched and installed with A horizontal pulley 302, the two ends of the pulley 302 are respectively fixed on the synchronous belt 304, and the motor drives the synchronous wheel to drive the synchronous belt to make the pulley 302 reciprocate on the sliding guide rail 303.

[0071] A rotary cylinder 306 is fixed on the trolley 302 (the rotation can also be controlled by a motor, not described in detail), and at least one manipulator mechanism is horizontally hinged at the front end of the trolley 302 . Its articulation mode is that a rotary sleeve 315 is provided at the lo...

Embodiment 2

[0084] Embodiment 2: Referring to all the attached drawings, a noodle packaging machine includes an automatic weighing device, a conveying device, a noodle trimming device and a packaging device described in Embodiment 1, and each device has a corresponding support or a common support. Above-mentioned each device is fixed and cooperates sequentially from back to front.

[0085] The dough bucket 139 of the automatic weighing device is located above the conveyor bucket 202 of the conveying mechanism. The PLC or the host computer controls the solenoid valve of the flour bucket of the weighing device at a time interval of Δt according to the uniform speed of the conveying device. A certain amount of loose vermicelli falls into the conveying bucket of the conveying device at regular intervals (every Δt time interval, there is just a conveying bucket positioned directly below the outgoing bucket). The front end of the conveying device is provided with a lifting cylinder 203 and at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com