Automatic disc loading method

An automatic, seedling tray technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of insufficient purchasing power of farmers, general operation effect, high price, etc., and achieve good implementation effect, low manufacturing cost, and agricultural cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

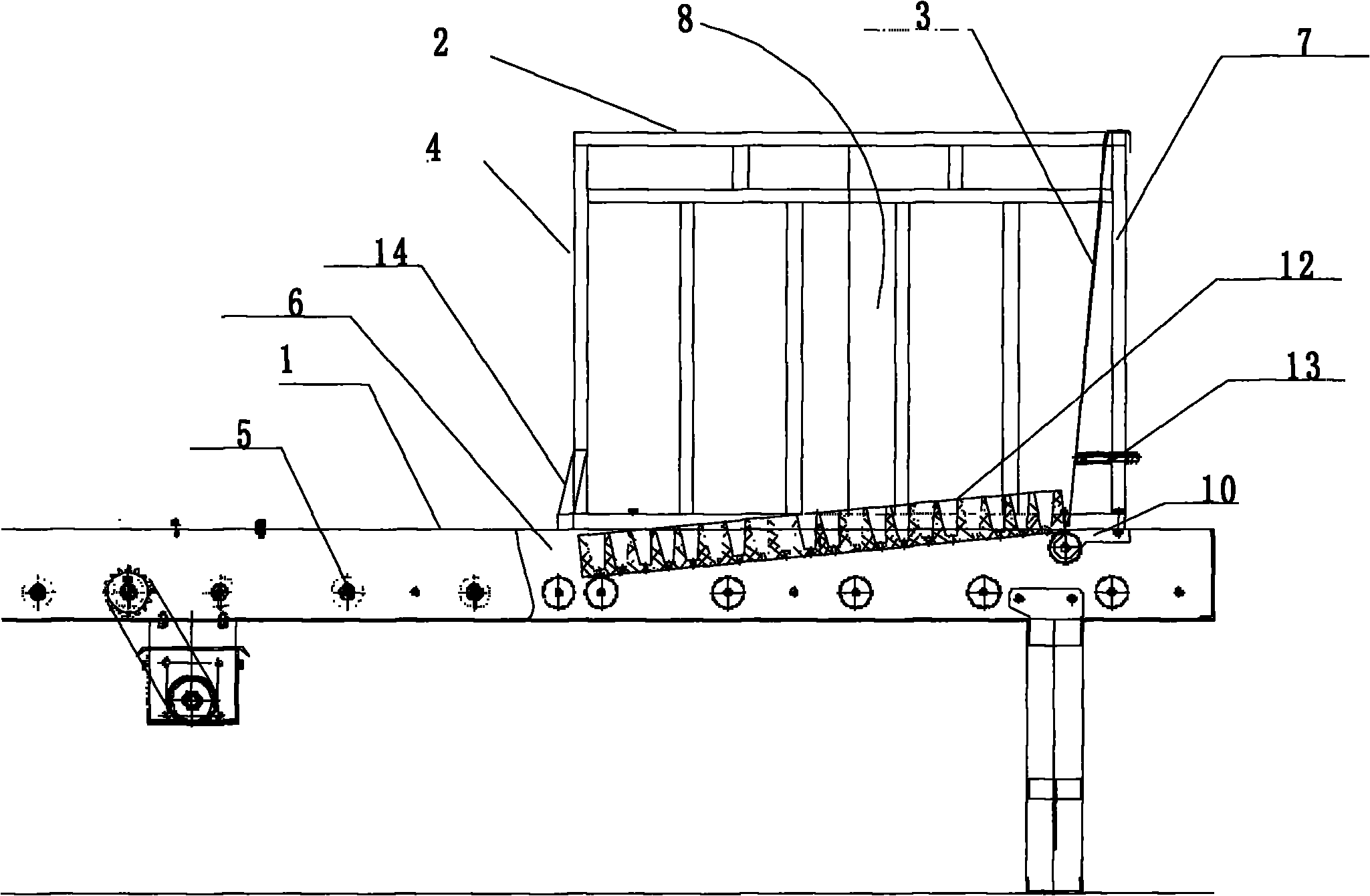

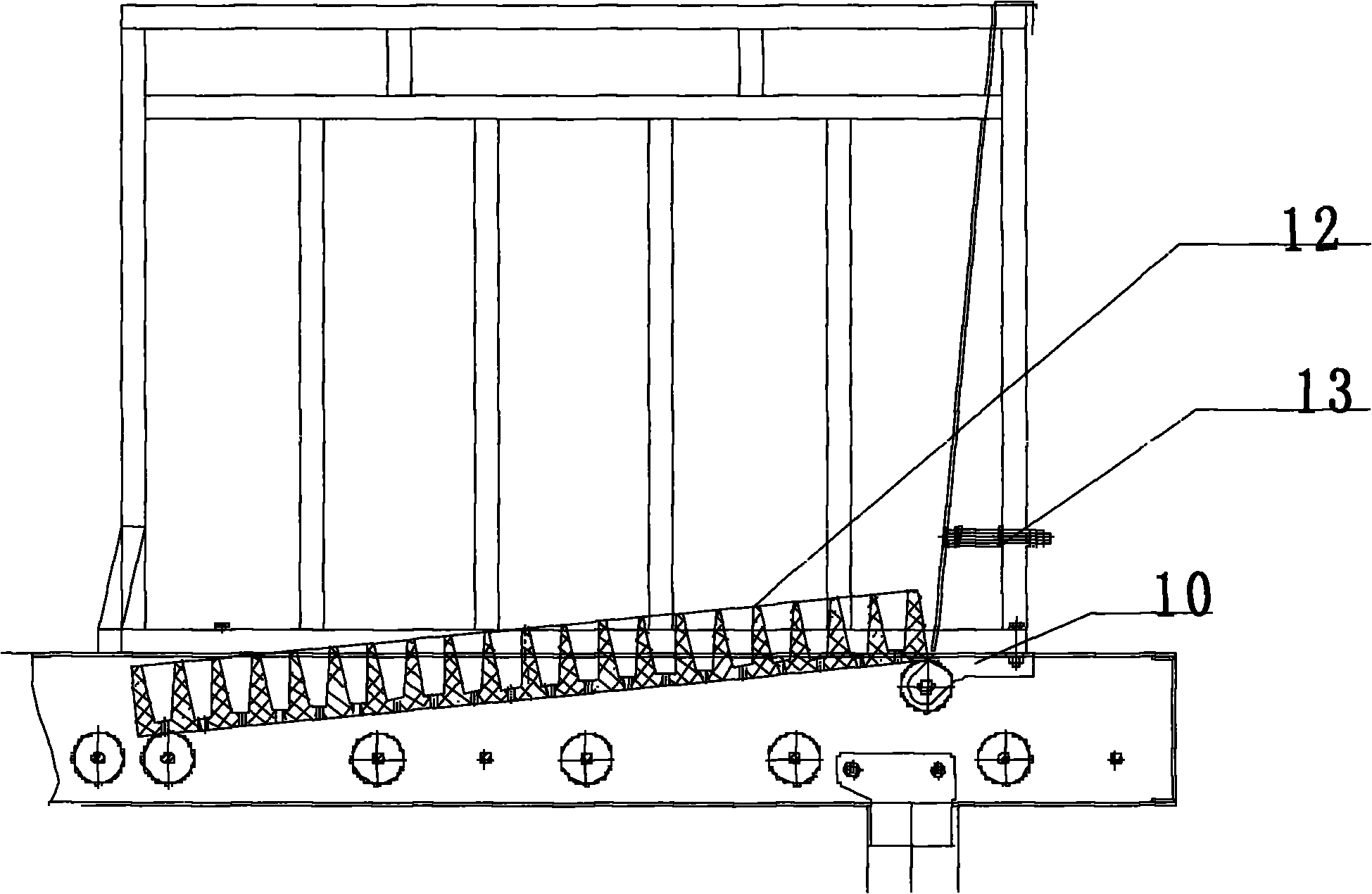

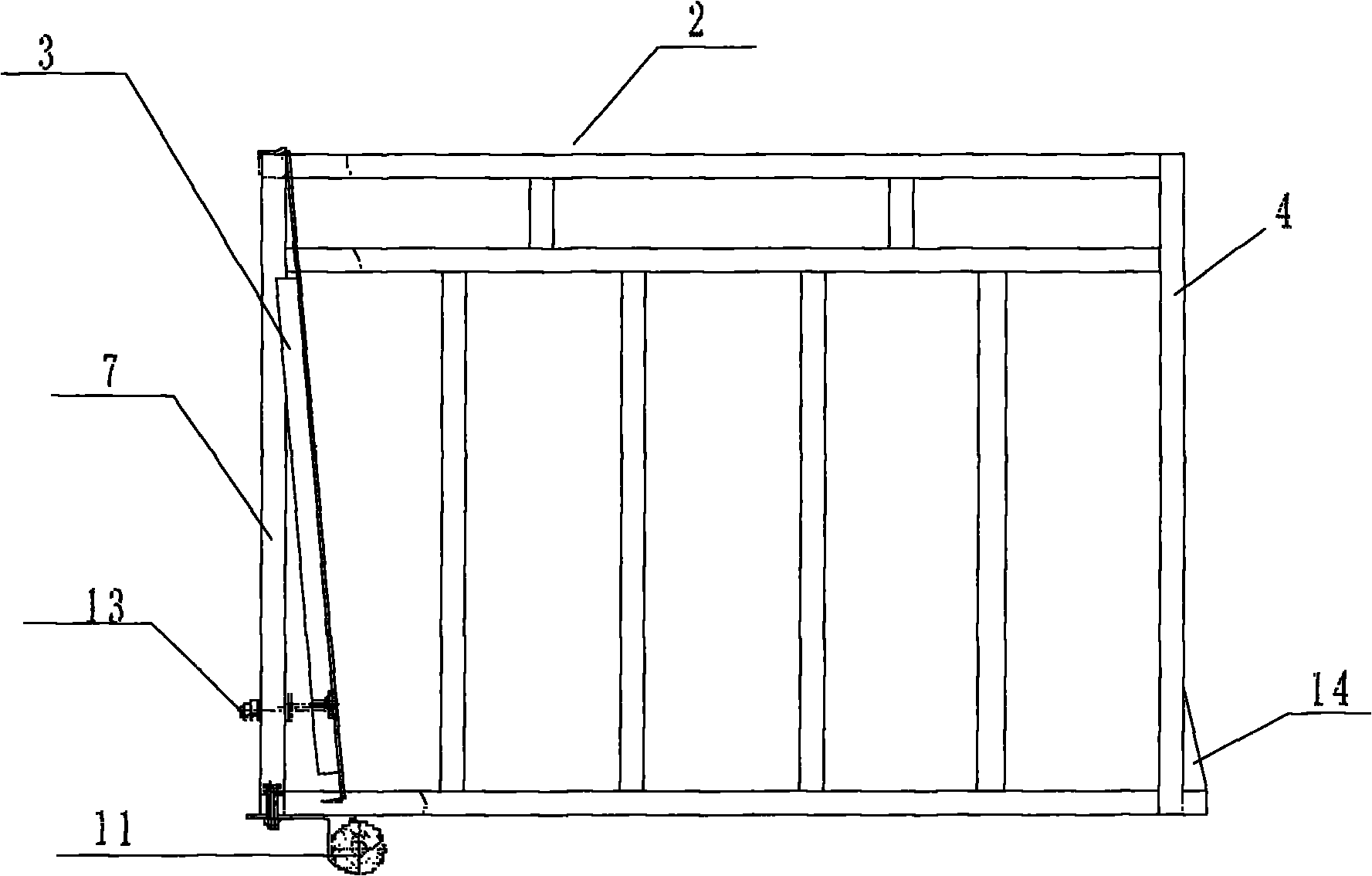

[0025] The loading method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] As shown in the figure, it includes: seedling production line 1, frame 2, upper plate guide plate 3, seedling tray outlet frame 4, track 5, seedling tray outlet 6, seedling tray guide frame 7, seedling tray inlet 8, pulley shaft 9, pulley Connecting plate 10, pulley 11, seedling raising tray 12, fastener 13, outward bending part 14 of lower end of seedling raising tray outlet frame.

[0027] The upper plate device is mainly welded by a three-sided rectangular frame. The whole frame 2 is box-shaped. The shape of the frame 2 must be adapted to the shape of the seedling tray. The disc 12 can be placed flat therein. Frame top and a side can be vacant, to be sent into seedling raising tray inlet 6. The outlet frame 4 of the seedling raising tray is a frame at the front of the frame of the upper tray device, which is set in a correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com