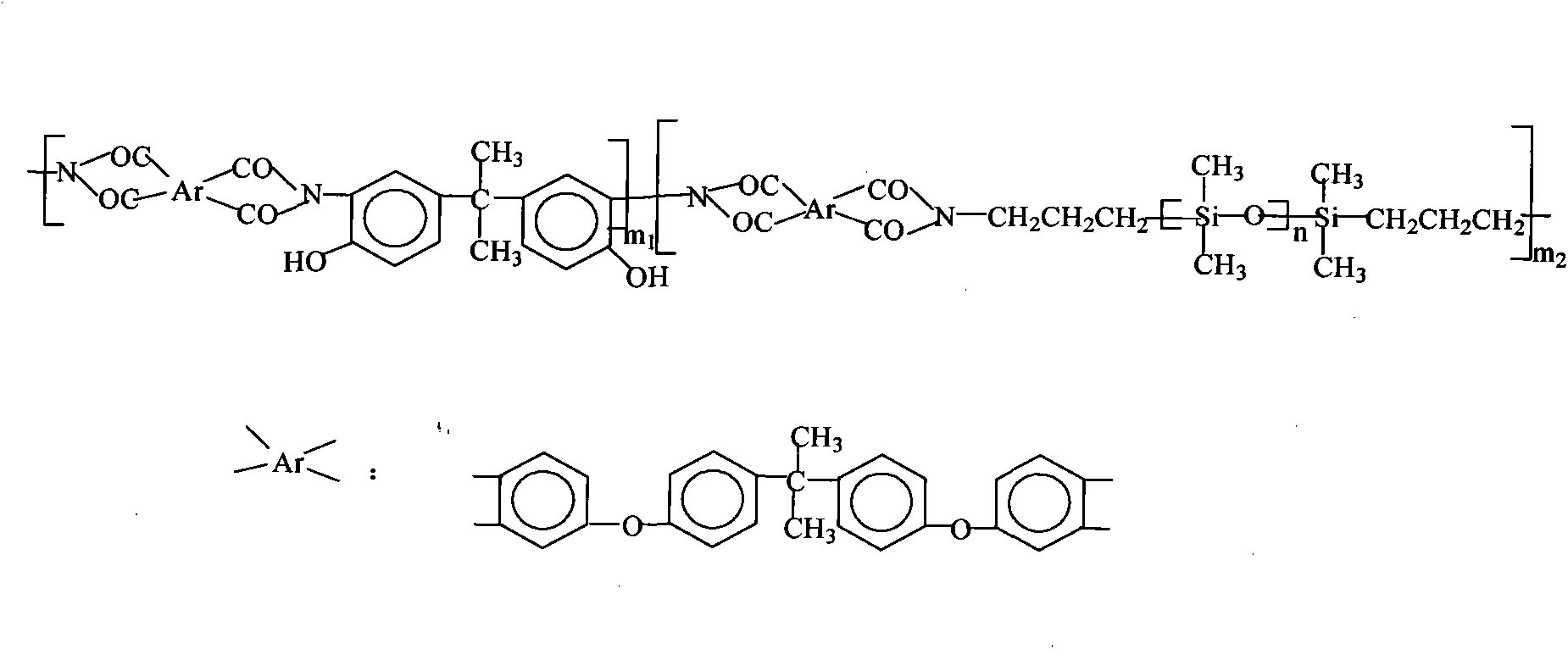

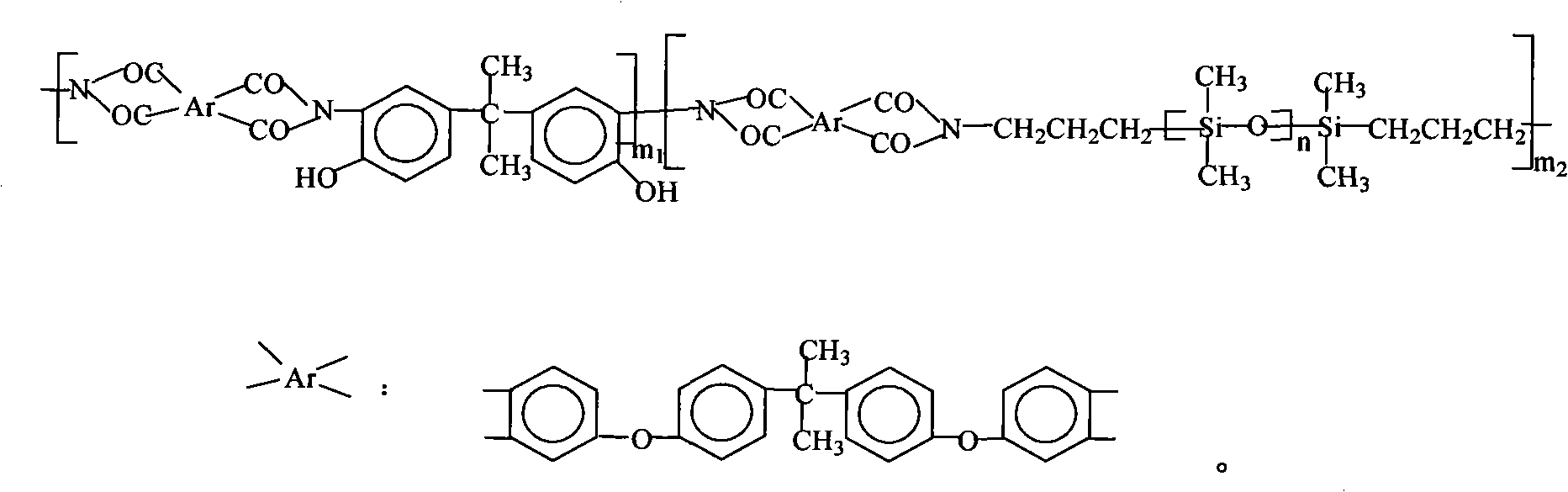

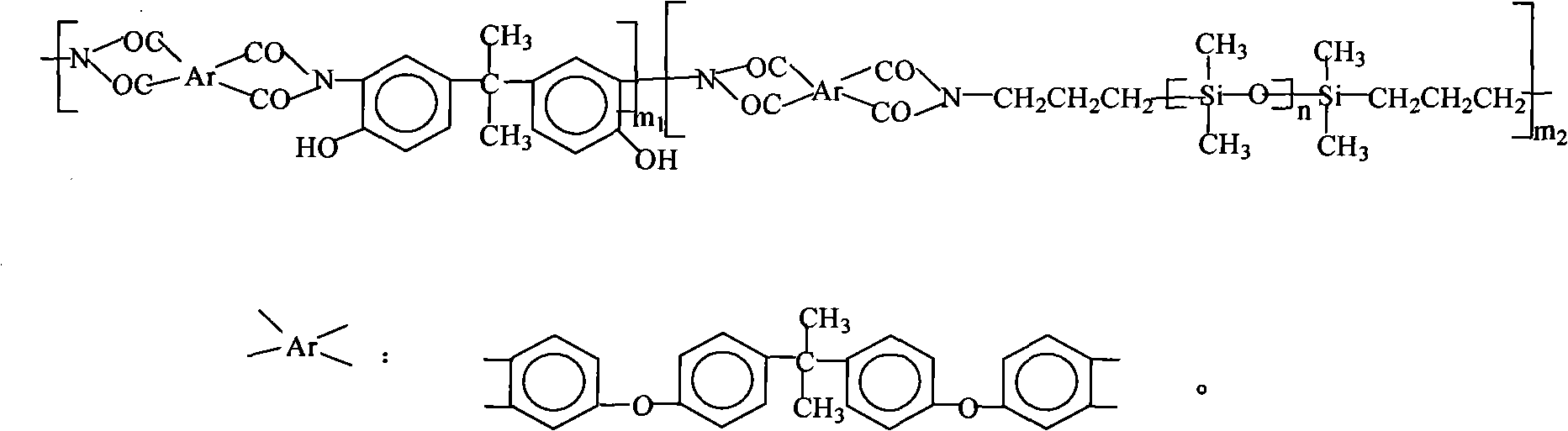

Epoxy-organic silicon polyimide adhesive and preparation method thereof

A silicon polyimide and adhesive technology, which is applied in the field of organic polymer adhesive preparation, can solve the problems of high price, unfavorable large-scale popularization and application, high cost of polyetherimide resin, etc., and achieves convenient operation, The effect of convenient source of reaction raw materials and excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 20.0 grams of silicone polyimide (SPI) resin, 30.0 grams of N, N, N', N'-tetraglycidyl-4,4'-diaminodiphenylmethane and 30.0 grams of thermoplastic novolac epoxy resin In the reaction kettle, react at 130°C for 0.5 hours, cool down, add 40.0 g of N,N-dimethylacetamide organic solvent, stir and dissolve at room temperature, it becomes a homogeneous transparent viscous liquid, and obtains component A.

[0033] With 2.1 grams of 4,4'-diaminodiphenylsulfone and 17.0 grams of 4,4'-bis(3-aminophenoxy)diphenylsulfone curing agent, 0.9 gram of 2-ethyl-4-methylimidazole accelerator Mix with 60.0 g of N,N-dimethylacetamide organic solvent, stir and dissolve at room temperature to obtain a homogeneous and transparent component B solution.

[0034] Mix components A and B, and stir evenly at room temperature to obtain an epoxy-silicon polyimide adhesive, which is designated as ESPIA-1.

[0035] Take an appropriate amount of ESPIA-1 epoxy-silicon polyimide adhesive, and evenly sp...

Embodiment 2

[0042] 30.0 grams of silicone polyimide (SPI) resin, 20.0 grams of N, N, N', N'-tetraglycidyl-3,3'-dimethyl-4,4'-diaminodiphenylmethane Add 40.0 grams of thermoplastic novolac epoxy resin to the reaction kettle, react at 130 ° C for 0.5 hours, cool, add 20.0 grams of N, N-dimethylformamide and 20.0 grams of dichloroethane organic solvent, and stir to dissolve at room temperature , in the form of a homogeneous transparent viscous liquid to obtain component A.

[0043] With 3.0 grams of 4,4'-diaminodiphenyl sulfone and 6.0 grams of 2,5-bis(2-trifluoromethyl-4-aminophenoxy) tert-butylbenzene curing agent, 1.0 grams of 2-ethylimidazole The accelerator was mixed with 60.0 g of N,N-dimethylformamide organic solvent, stirred and dissolved at room temperature to obtain a homogeneous and transparent component B solution.

[0044] Mix components A and B, and stir evenly at room temperature to obtain an epoxy-silicon polyimide adhesive, which is designated as ESPIA-2.

[0045] Take an ...

Embodiment 3

[0052] Add 20.0 grams of silicone polyimide (SPI) resin, 40.0 grams of N, N, N', N'-tetraglycidyl-4,4'-diaminodiphenylmethane and 30.0 grams of thermoplastic novolac epoxy resin In the reaction kettle, react at 130°C for 0.5 hours, cool down, add 35.0 g of N,N-dimethylacetamide organic solvent, stir and dissolve at room temperature, it becomes a homogeneous transparent viscous liquid, and obtains component A.

[0053] 2.0 grams of 4,4'-diaminodimethylmethane and 7.0 grams of methyltetrahydrophthalic anhydride curing agent, 1.0 grams of 2-ethyl-4-methylimidazole accelerator and 65.0 grams of N, N-dimethylacetamide organic The solvents were mixed, stirred and dissolved at room temperature, and a homogeneous and transparent component B solution was obtained.

[0054] Mix components A and B, and stir evenly at room temperature to obtain an epoxy-silicon polyimide adhesive, which is designated as ESPIA-3.

[0055] Take an appropriate amount of ESPIA-3 epoxy-silicon polyimide adhes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com