Ferulic acid glyceryl oleate polyvinylpyrrolidone nanometer fiber membrane and preparation and application thereof

A technology of ferulic acid glyceryl oleate and polyvinylpyrrolidone, which is applied in fiber treatment, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of low solubility and limited application, and achieve simple preparation method, convenient operation, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of spinning dope:

[0022] Dissolve 1 g of ferulic acid glyceryl oleate in 60 mL of chloroform and ethanol (80:20), then add 6 g of polyvinylpyrrolidone K60 under stirring, and continue stirring for 4 hours until the mixture becomes clear and transparent. Then use ultrasonic processor (500W) ultrasonic degassing for 15 minutes.

Embodiment 2

[0024] Preparation of instant ferulic acid olein nanofibrous membrane by high-voltage electrospinning:

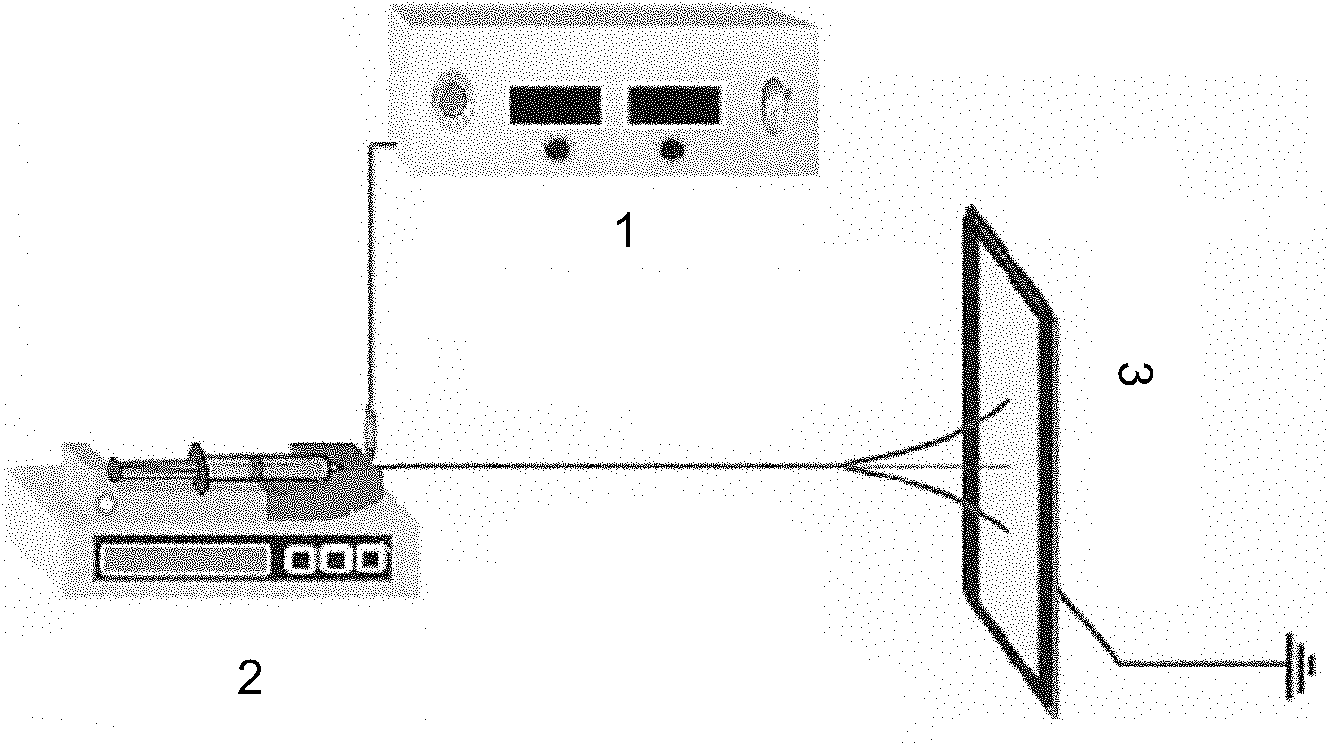

[0025] Pour the prepared solution into the solution reservoir (5mL syringe), use the flattened No. 6 injection needle as the capillary for jetting fine flow, connect the positive electrode of the high-voltage power supply, and connect the negative electrode with an aluminum foil receiving plate. Pump control, electrospinning was carried out according to the following conditions: the flow rate was 1.0mL h -1 , the distance between the receiving plate and the spinneret is 15cm, the voltage is 12kV, the ambient temperature is 20°C, and the ambient humidity is 65%. figure 1 It is the high-voltage electrospinning process diagram of the present invention.

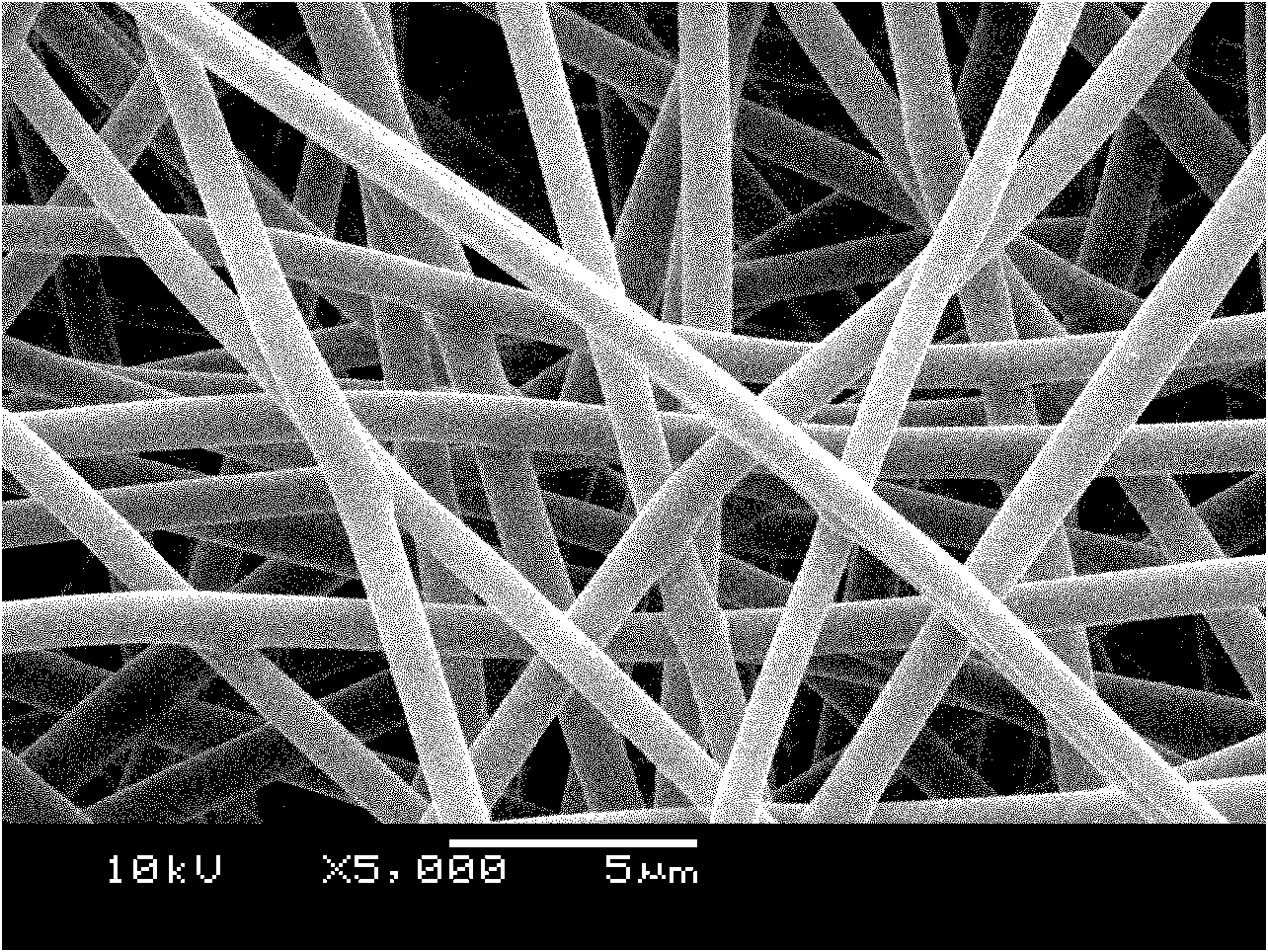

[0026] The fiber membrane electrospun under the above conditions was placed in a vacuum dryer and dried at room temperature for 24 hours, and then subjected to scanning electron microscope observation after spraying gold und...

Embodiment 3

[0028] Preparation of spinning dope:

[0029] Dissolve 1g of ferulic acid glyceryl oleate in 80mL of chloroform and ethanol (64:16), then add 7g of polyvinylpyrrolidone K40 under stirring, and continue stirring for 4 hours after the addition until the mixture becomes clear and transparent. Then use ultrasonic processor (500W) ultrasonic degassing for 15 minutes.

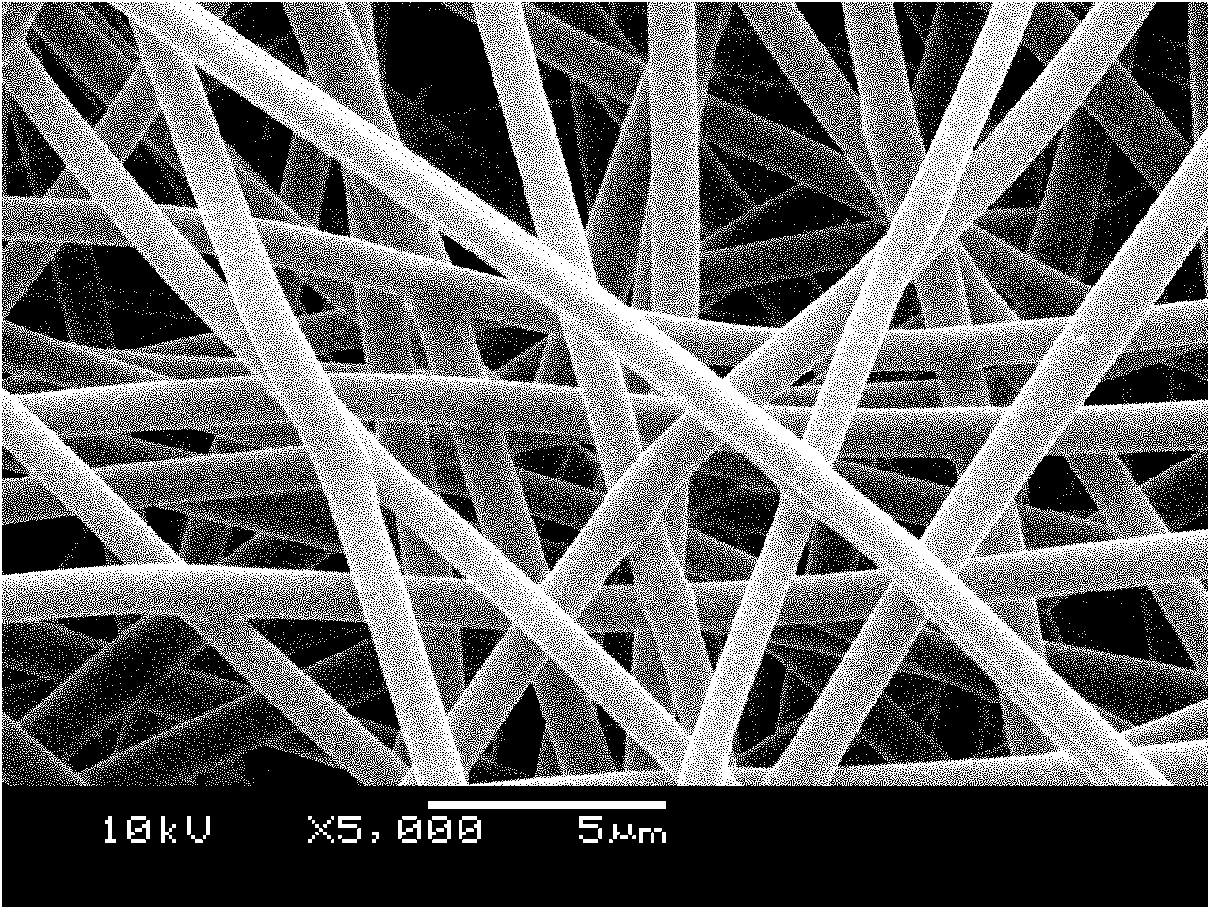

[0030] Preparation of instant ferulic acid olein nanofibrous membrane by high-voltage electrospinning:

[0031] Pour the prepared solution into the solution reservoir (5mL syringe), use the flattened No. 6 injection needle as the capillary for jetting fine flow, connect the positive electrode of the high-voltage power supply, and connect the negative electrode with an aluminum foil receiving plate. Pump control, electrospinning was carried out according to the following conditions: the flow rate was 0.8mL h -1 , the distance between the receiving plate and the spinneret is 10cm, the voltage is 14kV, the ambient tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap