Tool for filling and backwashing oil well

A technology for backwashing wells and tools, which is applied in wellbore/well parts, cleaning tools, earthwork drilling and mining, etc. It can solve the problems of secondary or multiple filling, short sand prevention period, long production period, etc., and achieve portable Strong power, prolonging the effective period of sand control, and long effective period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

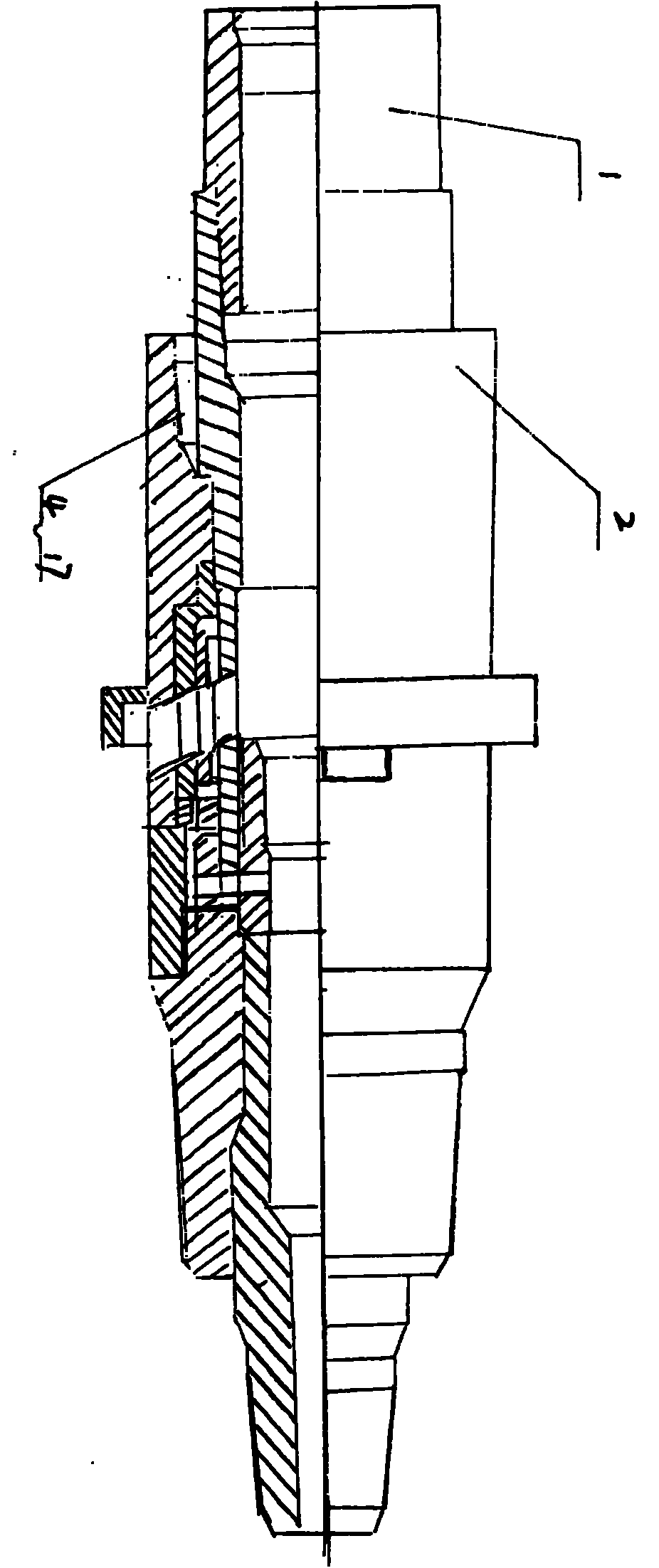

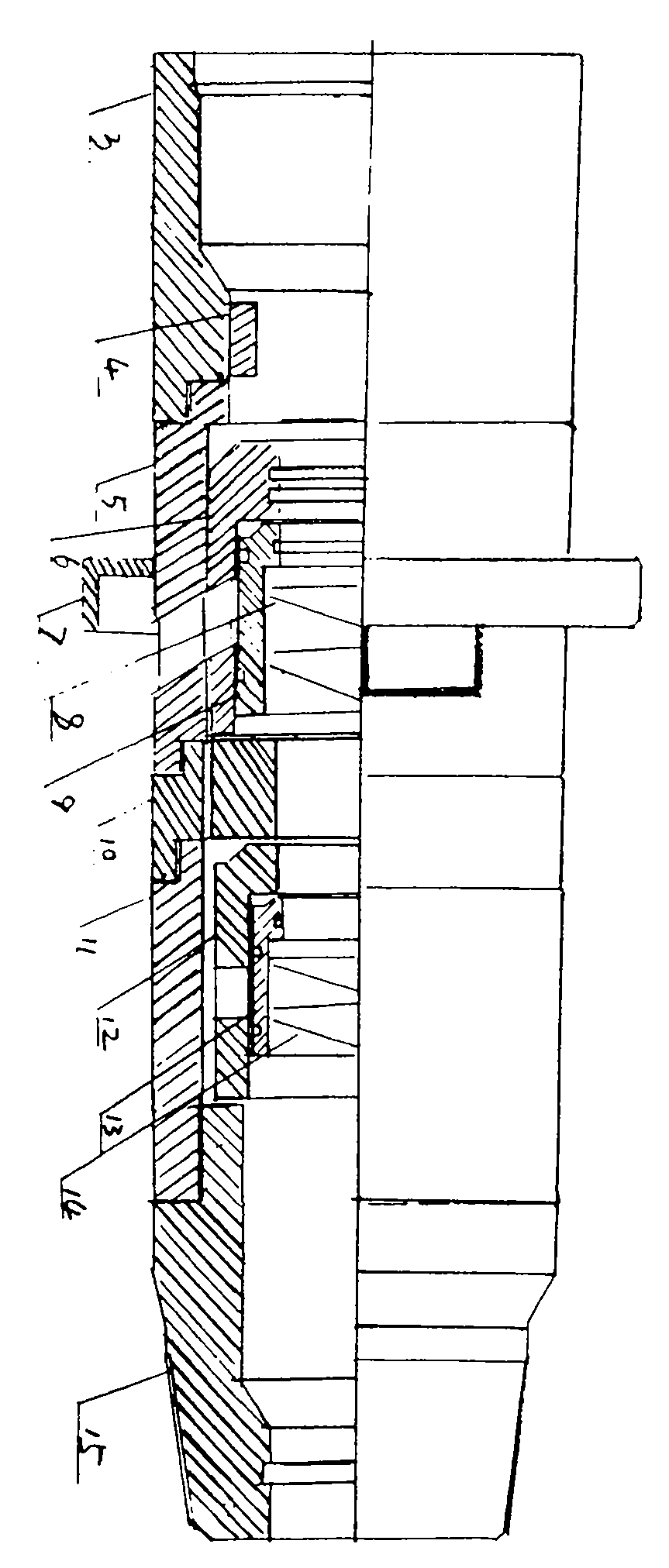

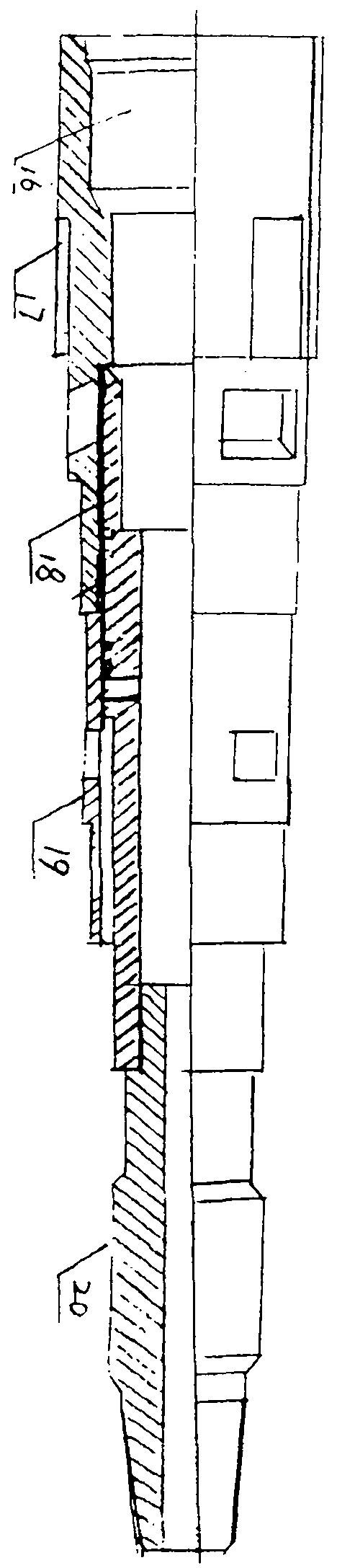

[0021] The filling outer tube 1 is connected to the upper end of the filling outer cylinder 5 by threading one end of the positioning sleeve 3, and the positioning key 4 is fixedly connected to the inner wall of the positioning sleeve 3 close to the filling outer cylinder 5, and the inner wall of the filling outer cylinder 5 is welded to the filling inner cylinder 6. Connect the guide ring 7 on the outer wall of the filling outer cylinder 5. The guide ring 7 half-closes the filling hole to straighten the filling orientation when going down the well. Connect the upper sealing cylinder 9 on the inner wall of the filling inner cylinder 6 opposite to the guide ring 7. There are 3 filling holes on the filling inner cylinder 6 at the junction of the sealing cylinder 9, and there are 3 filling holes on the corresponding filling outer cylinder 6. There is a spring I8 in the upper sealing cylinder 9, and the lower end of the filling outer cylinder 5 passes through the connector 10. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com