Valve for compressed gas collecting bottle and concentrating pneumatic control method thereof

A technology of clustering bottle group and compressed gas, applied in container filling method, container discharging method, gas/liquid distribution and storage, etc., can solve the problems of inconvenient remote and centralized control, difficult to guarantee safety, low work efficiency, etc. To achieve the effect of improving the working efficiency of deflation, beautiful appearance and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

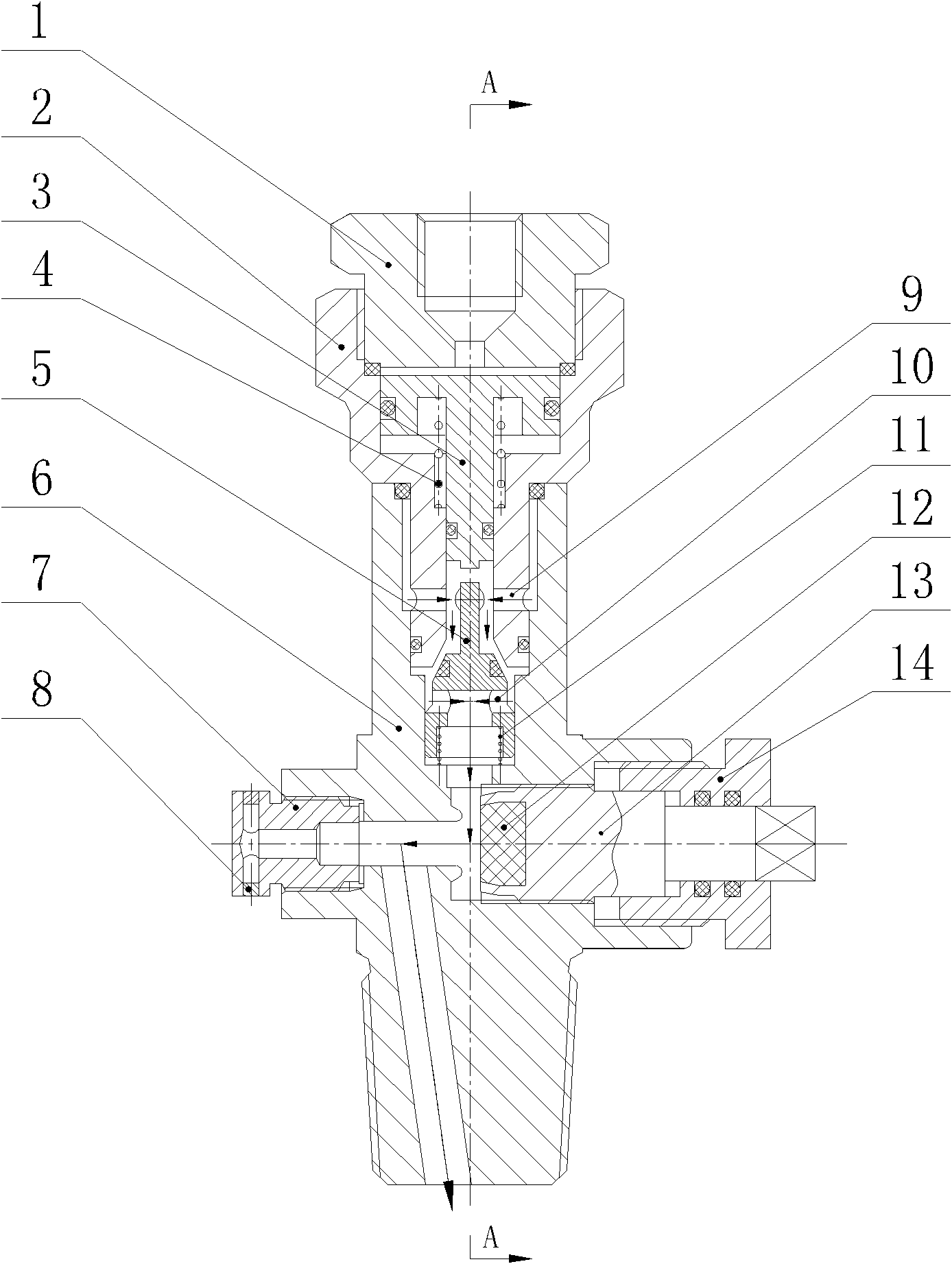

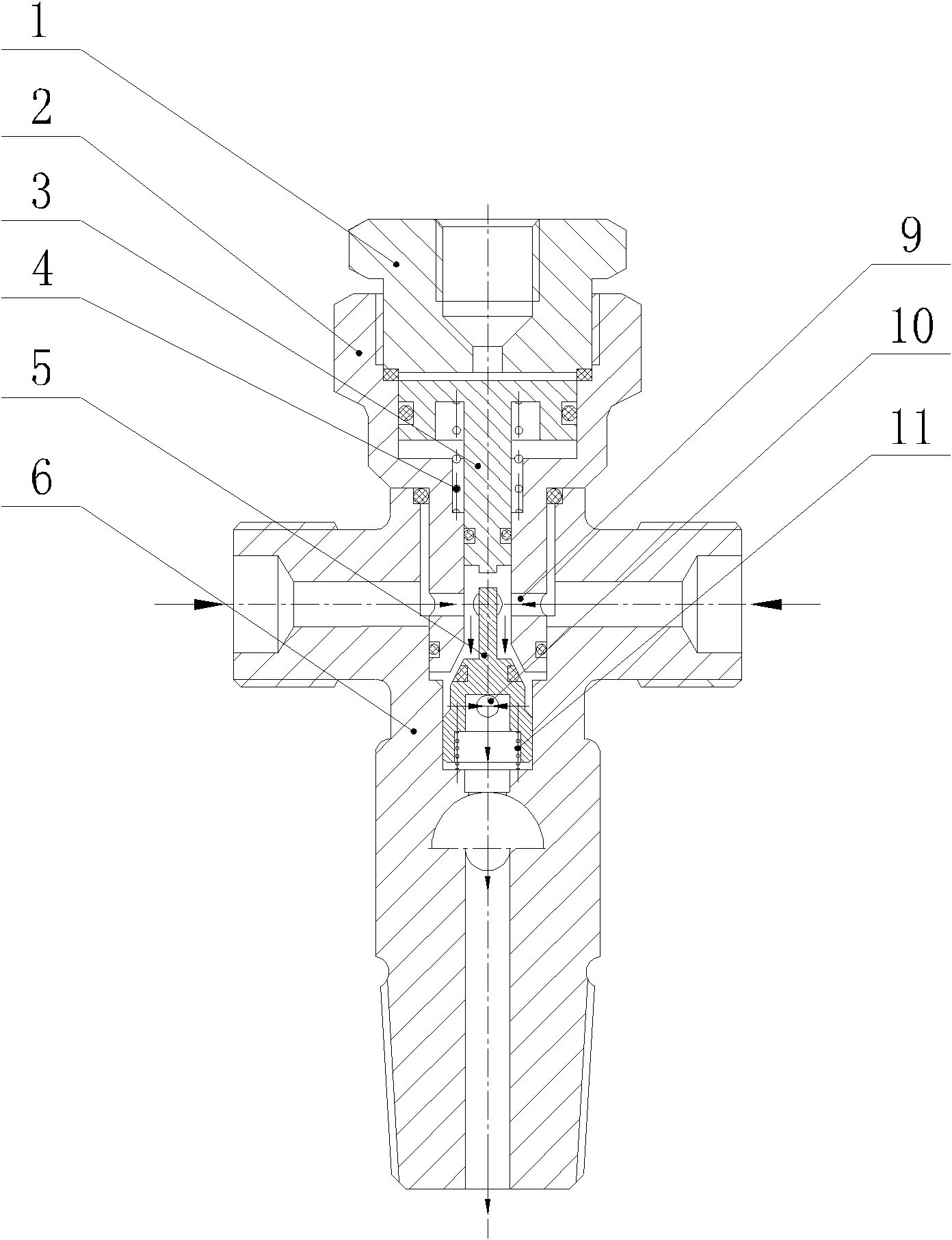

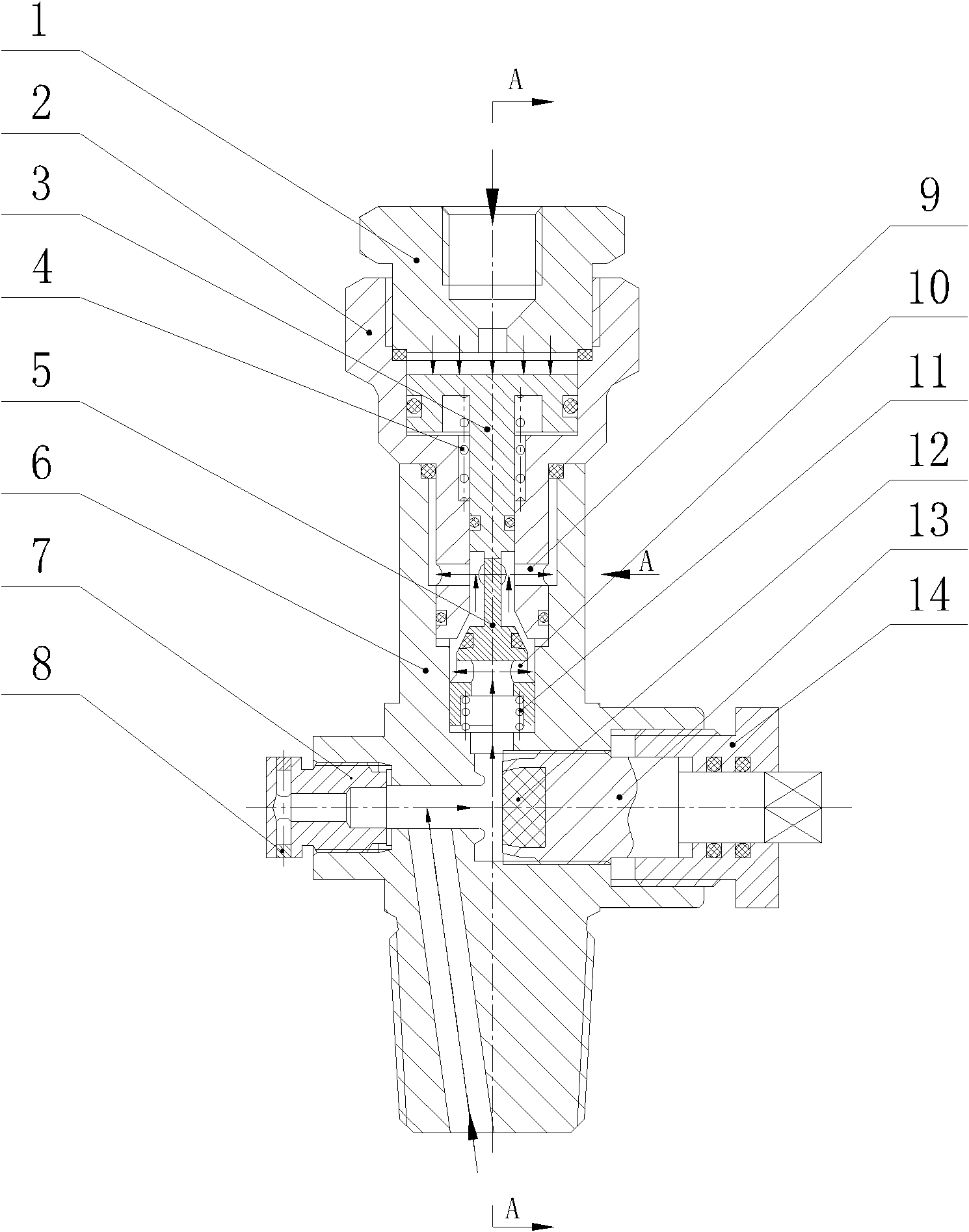

[0010] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] See attached Figure 1-7 , a special valve for a compressed gas cluster bottle group, which includes an end cap 1, a connecting sleeve 2, a piston 3, a pressure spring 4, a tapered valve core 5, a valve body 6, a safety screw plug 7, a return spring 11, and an emergency manual switch components.

[0012] The return spring 11 is mounted on the lower end of the upright inner cavity of the valve body 6, and the lower end cavity of the conical valve core 5 with a sealing ring on the outer groove is set on the top of the return spring 11, and the lower end cavity wall of the conical spool 5 There is a vertical spool through hole 10.

[0013] The external thread of the connecting sleeve 2 is connected to the upright inner cavity of the valve body 6. The inner edge of the upper end of the valve body 6 is equipped with a sealing ring. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com