Automatic inspection system of truck tank

An automatic inspection and tanker technology, applied in the field of automatic inspection systems for automobiles and tankers, can solve the problems of low degree of inspection automation, low work efficiency, affecting the accuracy, objectivity and scientificity of inspection and testing, and achieves improved inspection work efficiency, The effect of precision improvement and overall design humanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

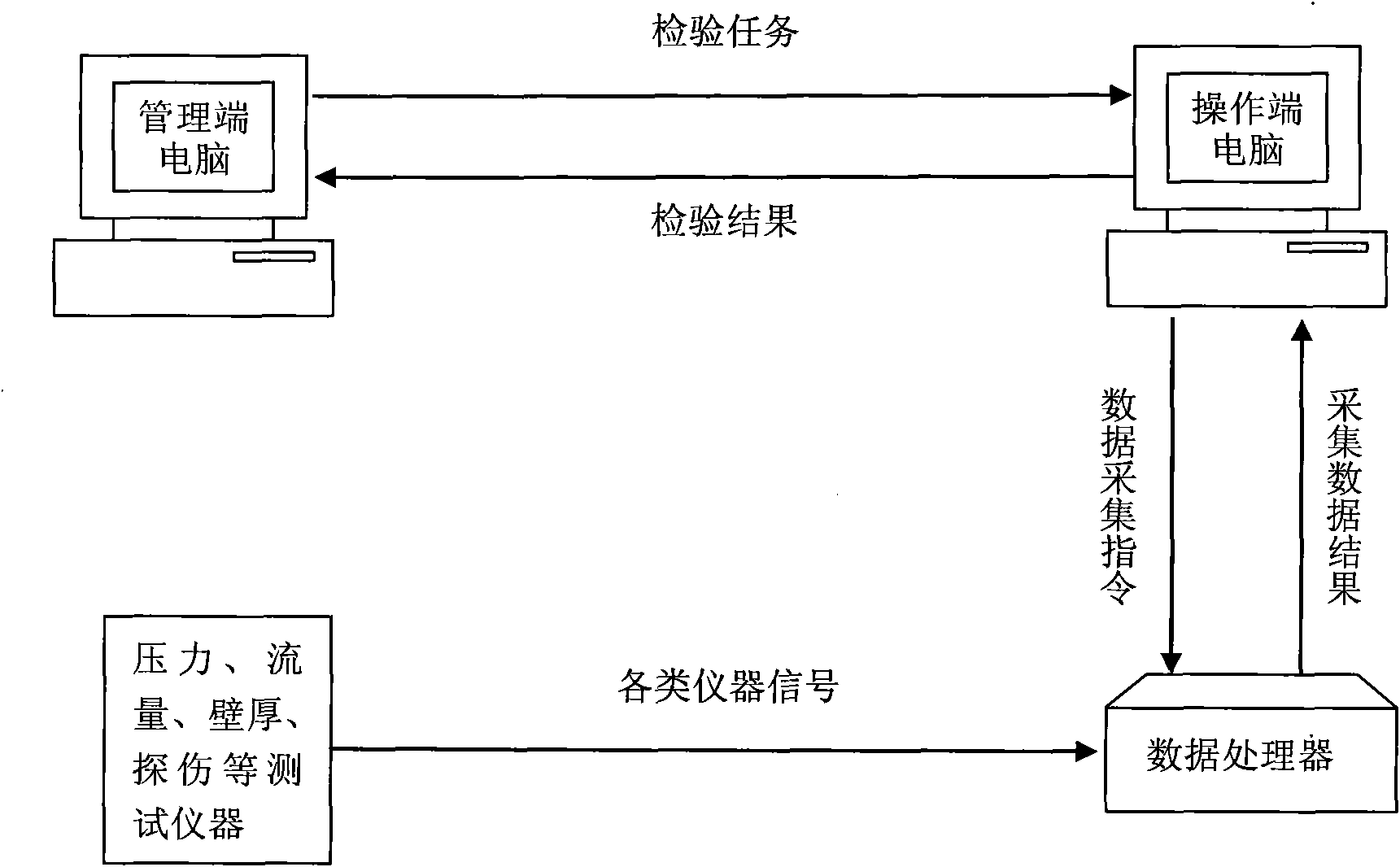

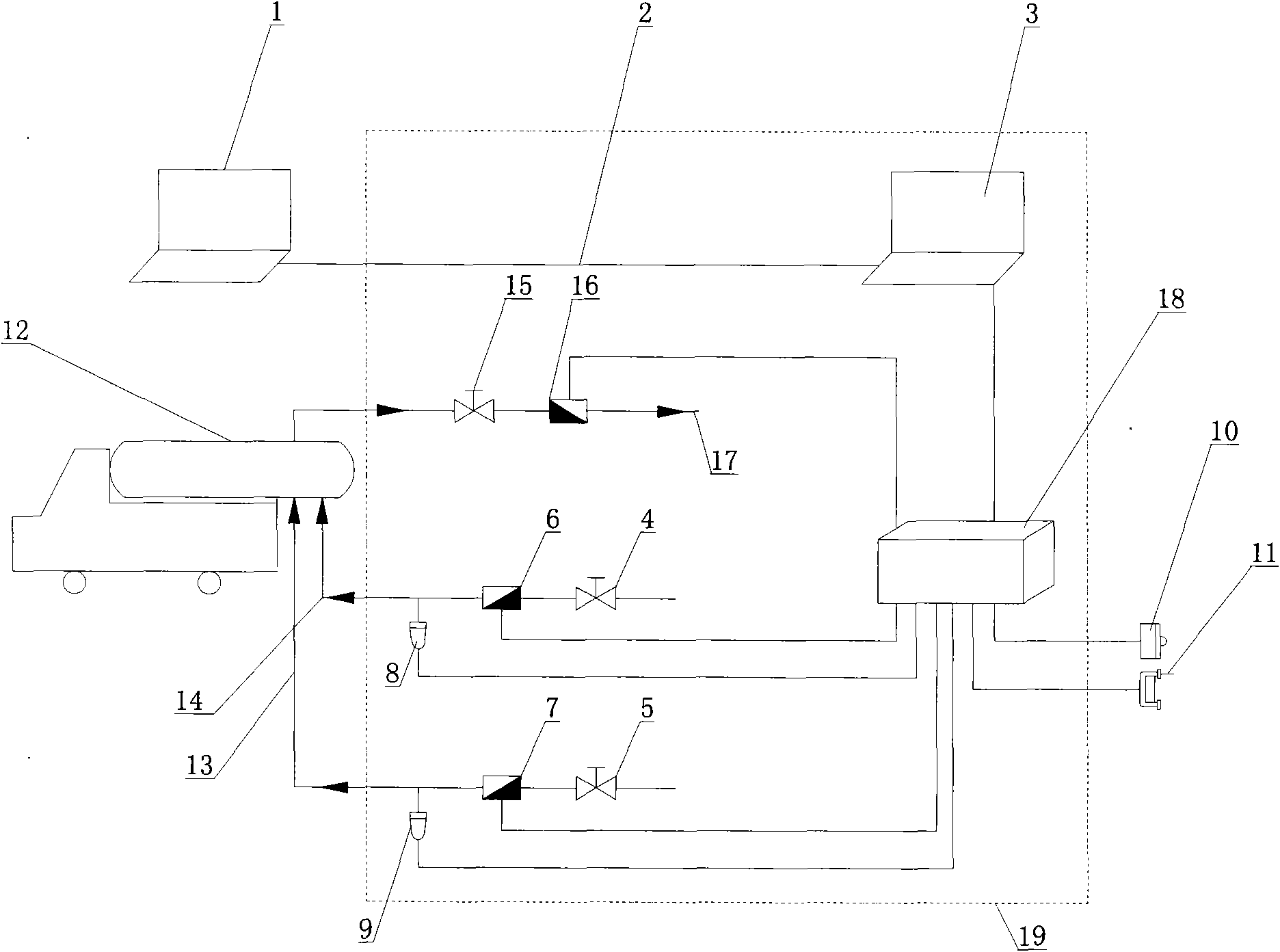

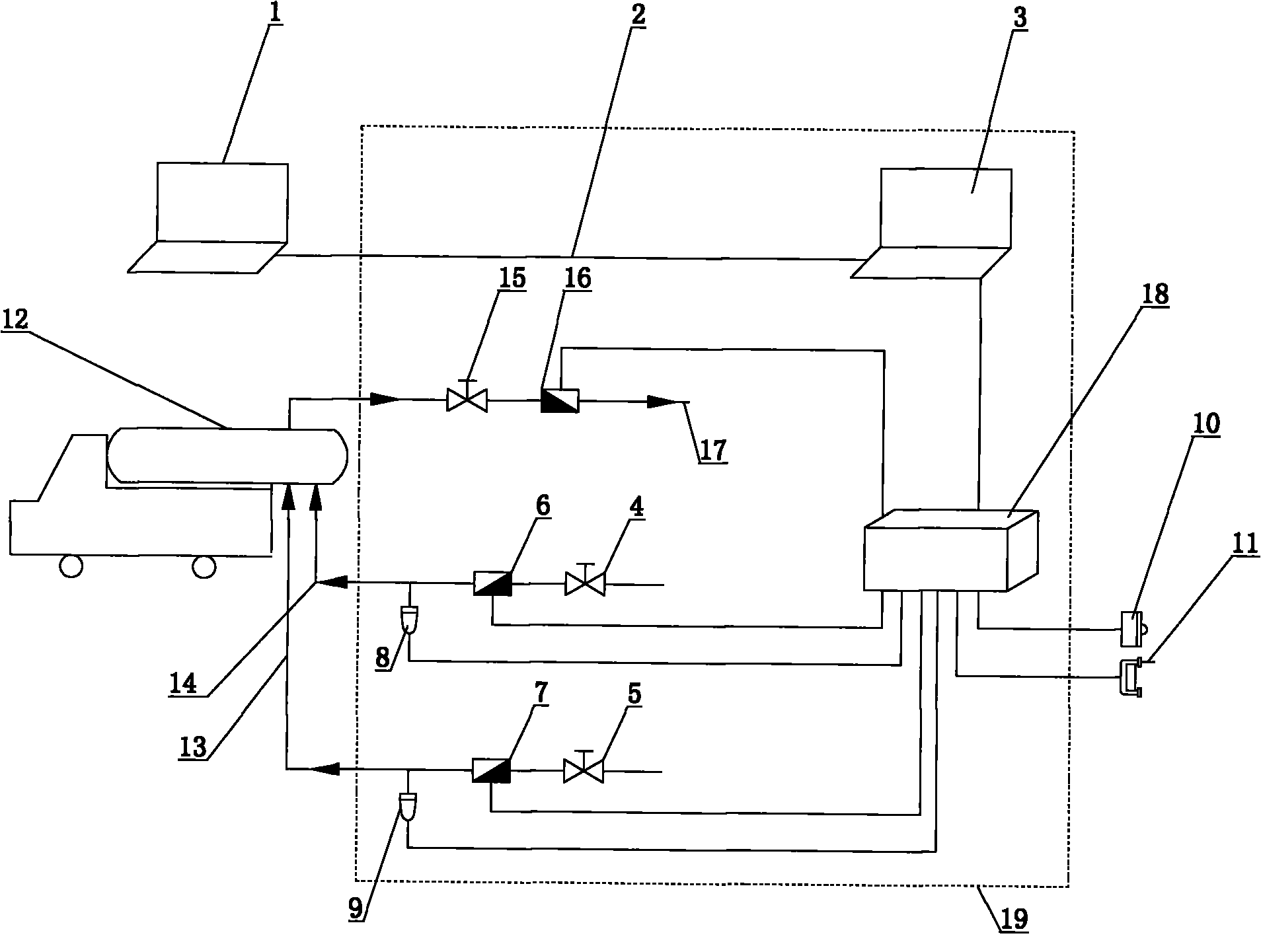

[0016] Such as figure 1 As shown, the air intake pipeline and the water inlet pipeline of the comprehensive inspection platform of the automatic inspection system for automobile tank cars of the present invention are connected to the tank car storage tank, and the water source and the air source required for the inspection of the tank car are delivered to the tank car to be inspected, and the water and gas discharge pipeline will be checked. of water vapor discharge. The data processor is connected to various inspection and testing instruments (pressure, flow, wall thickness, flaw detection, etc.), and the operating computer is connected to the management computer through the network. The operating computer and the management computer can be different computers that communicate with each other, and are respectively located behind the inspection platform and the managem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com