Well-cementing operation simulation training system

A simulation training system and cementing technology, applied in educational appliances, instruments, teaching models, etc., can solve the problems of economy, personal loss, poor operator's practical ability, no liquid level and cement slurry simulation, etc., and achieve simulation control. The module is simple, improves the ability of on-site learning, and facilitates the effect of human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

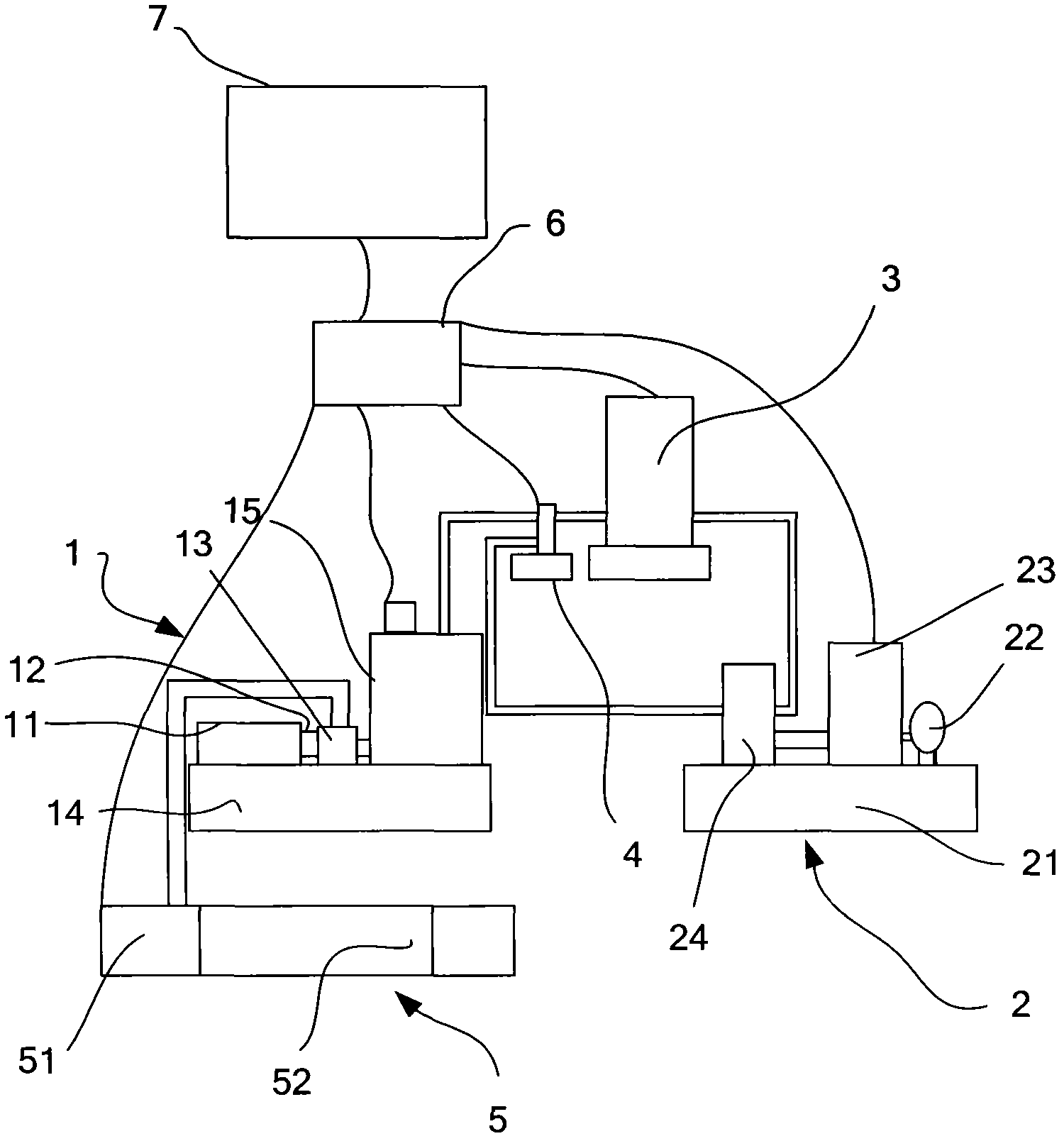

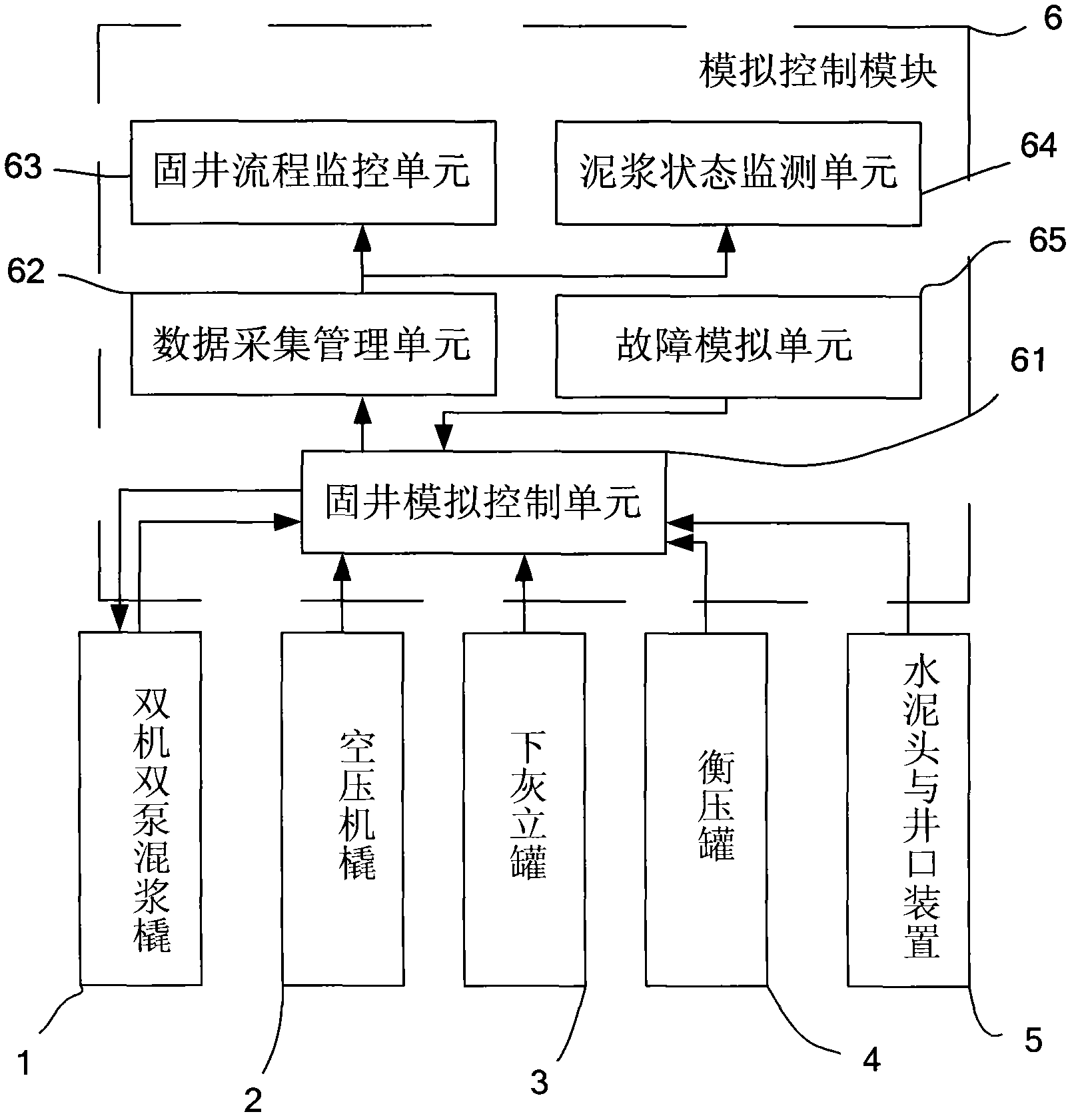

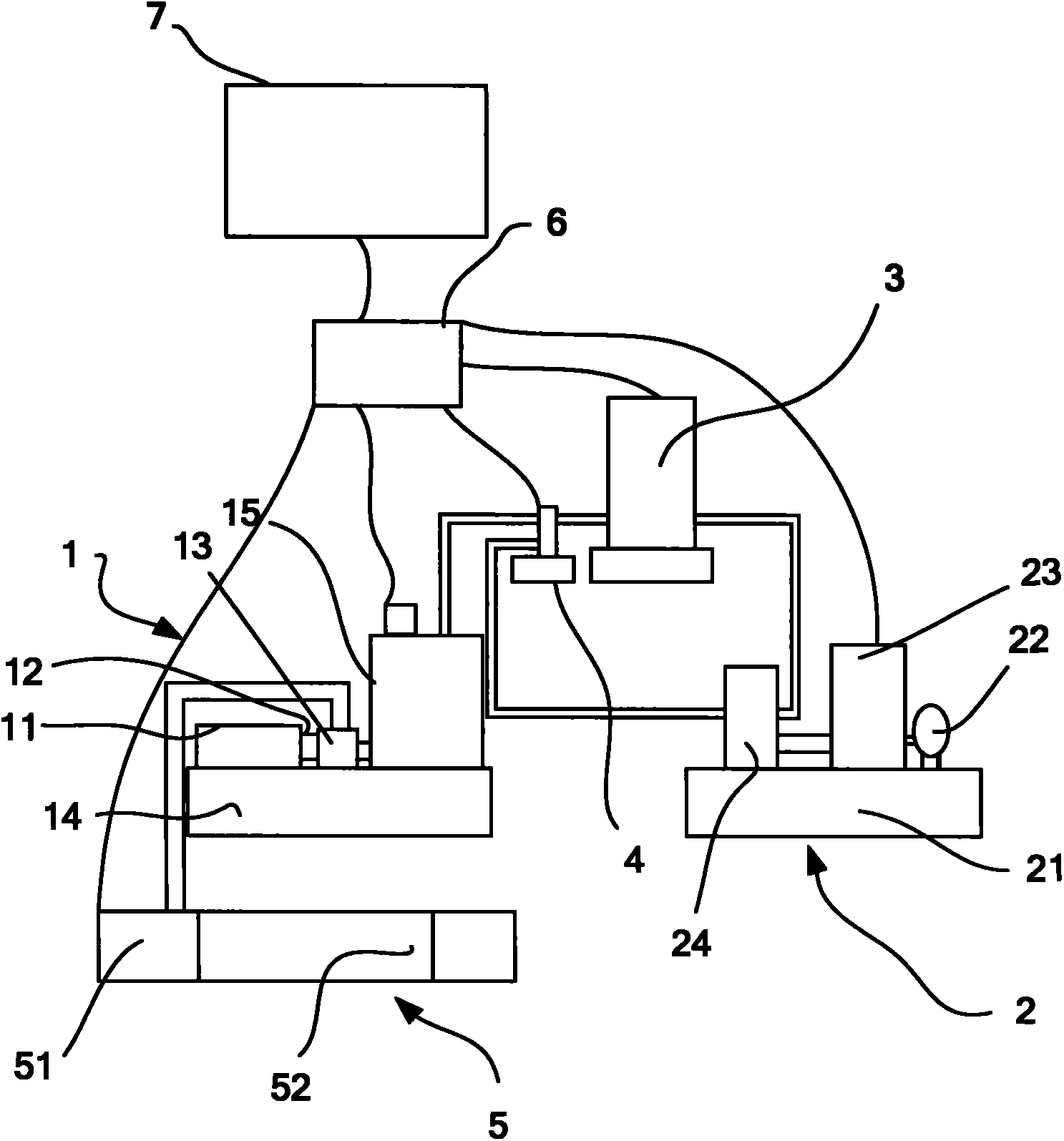

[0026] Such as figure 1 , figure 2 As shown, the present invention includes a two-machine double-pump mixing skid 1, an air compressor skid 2, a vertical ash tank 3, a pressure balance tank 4, a cement head and wellhead device 5, an analog control module 6 and a multimedia teaching system 7.

[0027] The present invention includes an ash path and an air path. The ash path includes the lower ash vertical tank 3 and the pressure balance tank 4. The ash storage is simulated in the lower ash vertical tank 3. Simulate ash delivery in the tank body 15 of the double-machine double-pump mud mixing skid 1, and simulate the mixing of the gray-water mixture in the tank body 15 of the double-machine double-pump mud mixing skid 1 to simulate mud, and the dual-machine double-pump mud mixing skid 1 The middle plunger pump 13 is driven by the engine 11 and the transmission case 12 to simulate injecting the mixture into the cement head and the wellhead device 5 .

[0028] The air path inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com