Pad structure of circuit board and manufacturing method thereof

A technology for circuit boards and circuit board circuits, which is applied in chemical/electrolytic methods to remove conductive materials, print circuit components, and electrically connect printed components, etc., can solve problems such as high temperature oxidation, poor heat dissipation, etc. Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

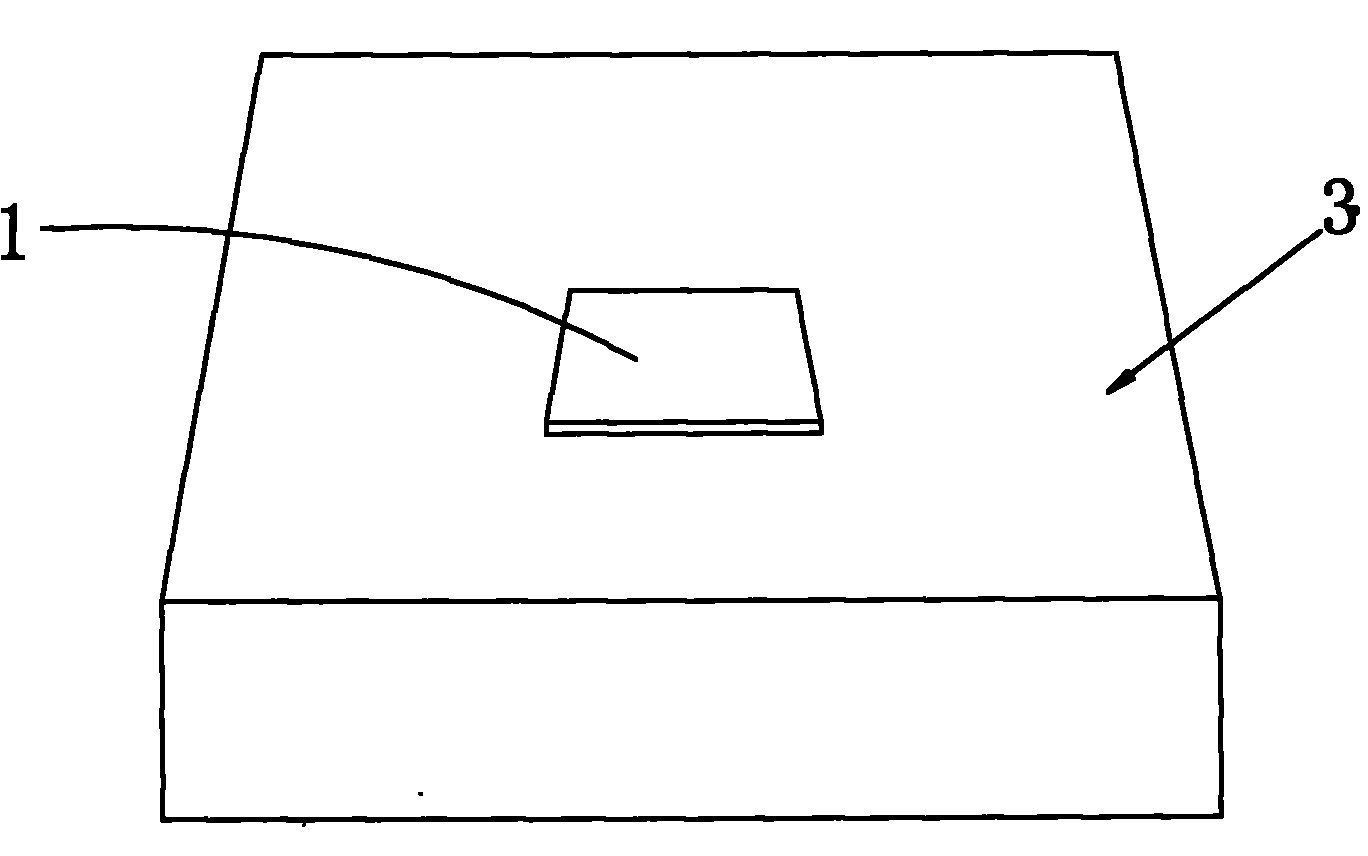

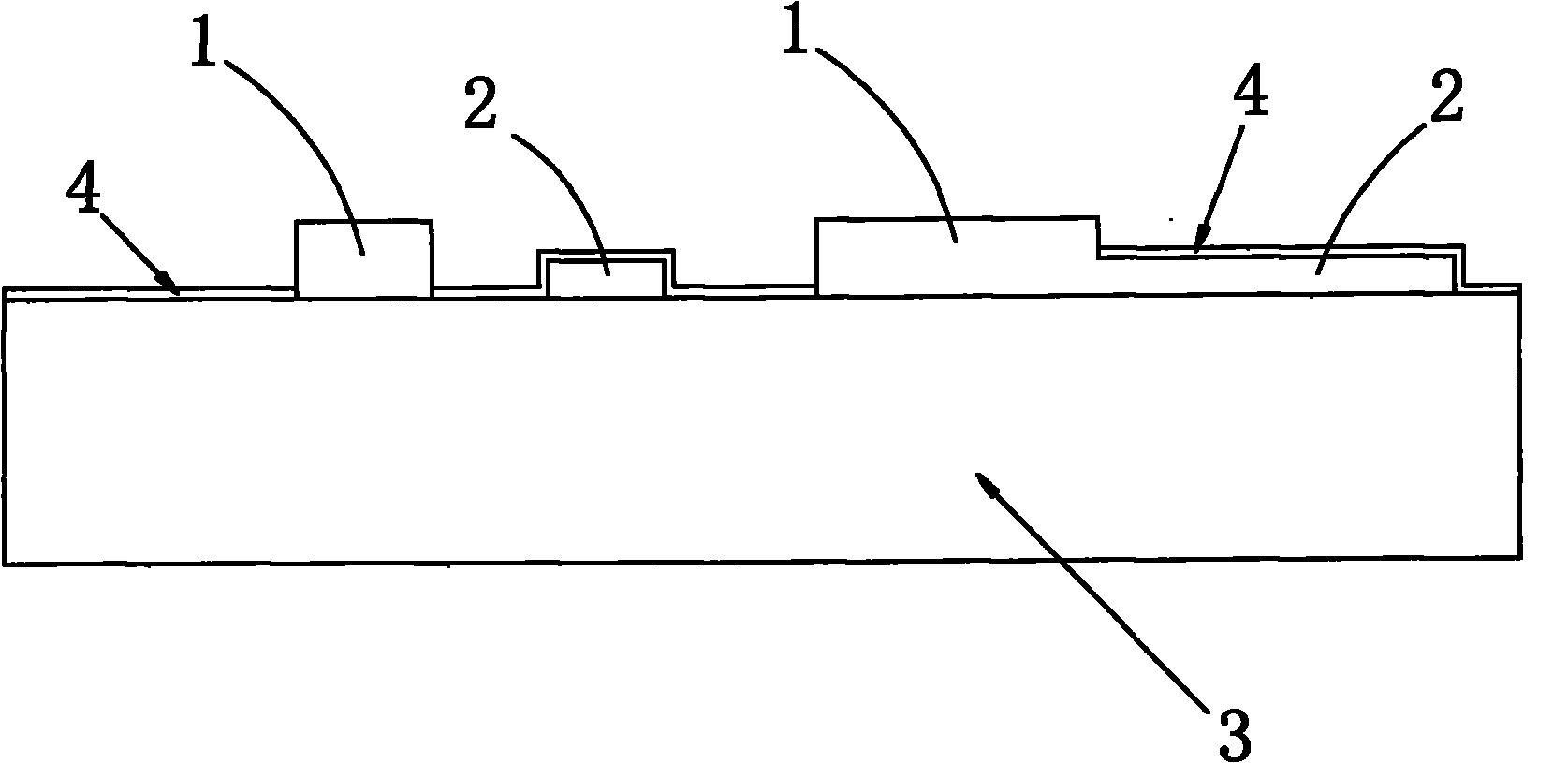

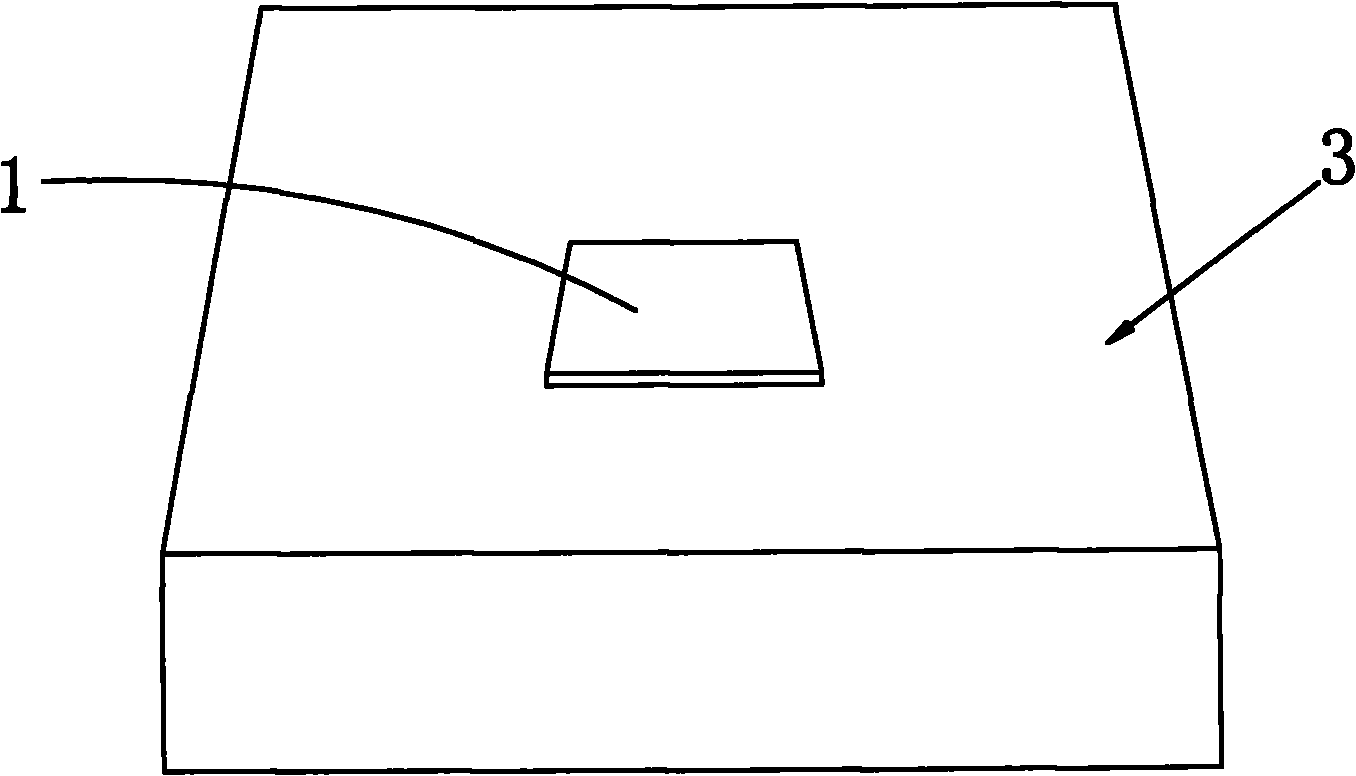

[0018] Embodiment: A pad structure of a circuit board. The circuit board 3 is provided with several pads 1 that are not covered by the solder resist layer 4 on the surface of the circuit board and connected to the circuit board lines 2. The pads 1 are higher than the circuit board. board surface.

[0019] The pad 1 is a metal pad formed by synchronous etching with the circuit board line 2 on the same metal layer closest to the surface of the circuit board, and the realization method that the pad 1 is higher than the surface of the circuit board is: the pad 1 The metal layer of the pad 1 is thicker than the metal layer of the circuit board line 2, and the thickness difference between the metal layer of the pad 1 and the metal layer of the circuit board line 2 is greater than the thickness of the solder resist layer 4 on the surface of the circuit board.

[0020] The realization method that the metal layer of the pad 1 is thicker than the metal layer of the circuit board circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com