Cleansing bars

A soap bar and cleaning technology, applied in the direction of alkali soap/ammonium soap composition, soap detergent composition, soap detergent and other compounding agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

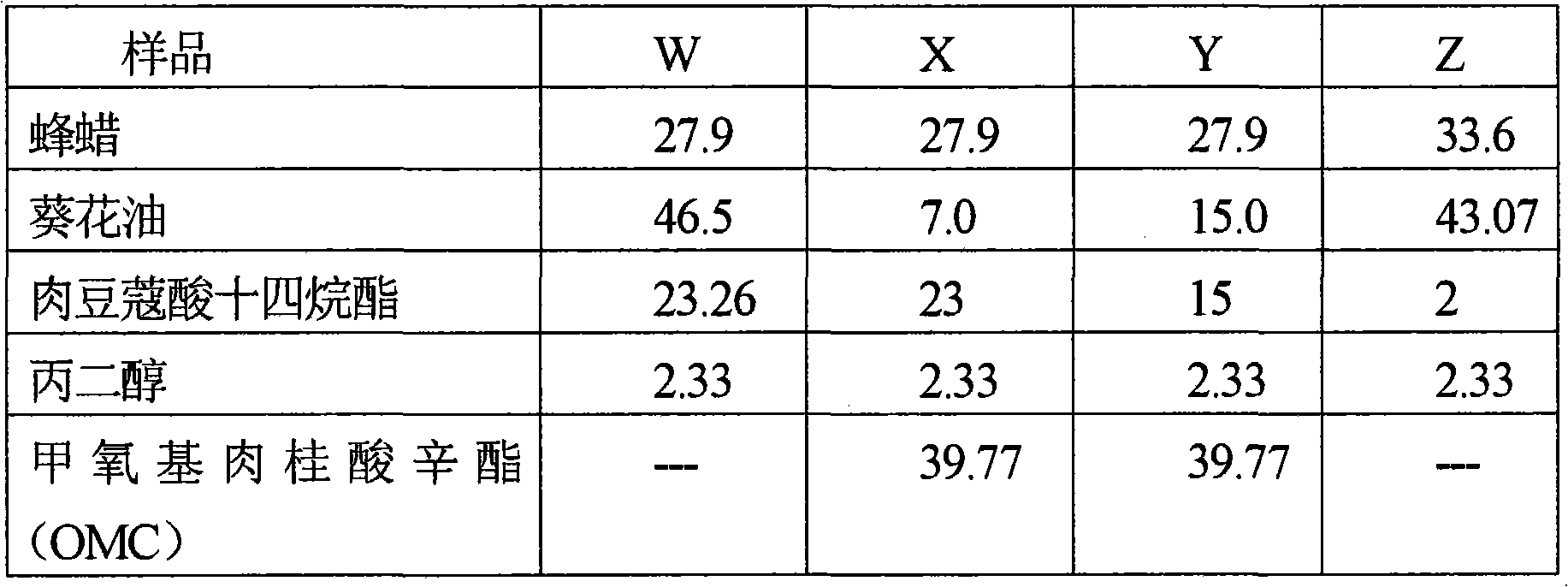

[0044]Preparation of Cleansing Bars

[0045] In one embodiment, a cleansing bar containing a combination of wax, sunflower oil, and myristyl myristate (hydrophobic blend) is prepared by heating the wax until it melts and forms a molten wax solution (hydrophobic blend). ); while heating, other components including sunflower oil, myristyl myristate, optional ethylene glycol, optional octyl methoxycinnamate, and optional chromium oxide green are added to the wax melt solution; stir to obtain a homogeneous solution; cool the solution to 50-55°C; then add the homogeneous solution to the soap component (hydrophilic component) during extrusion; then extrude to form a clean bar .

[0046] In one embodiment, the cleansing bars of the present invention are prepared using (hybrid) extrusion equipment (eg combining two components). See patents U.S. 3,940,220 (D'Arcageli et al.), U.S. 4,096,221 (Fischer et al.); U.S. 7,128,901 (Jonas et al.), U.S. 4,318,878 (Horning); U.S. 6,878,319 (Bro...

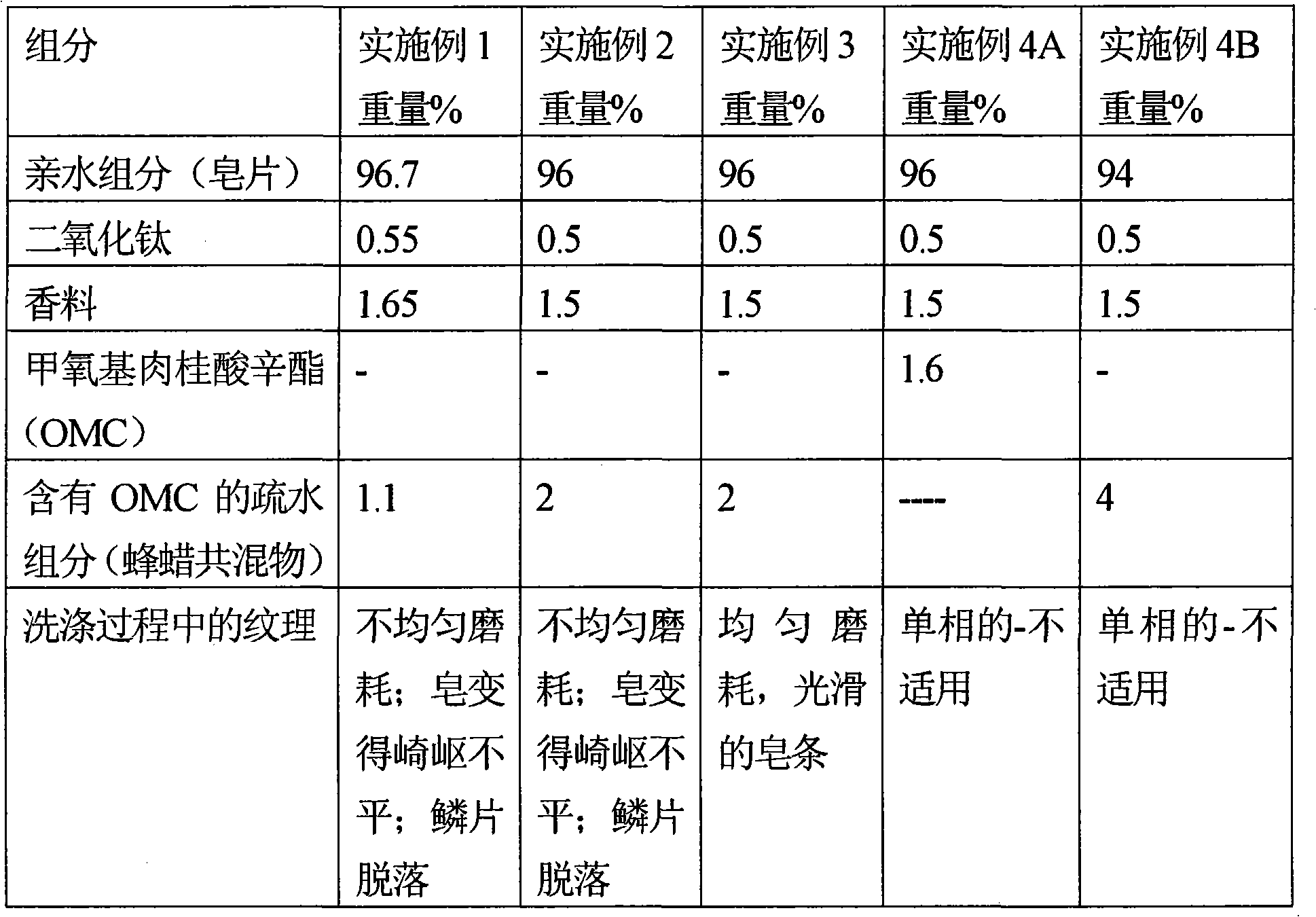

Embodiment 1

[0056] A cleansing bar composition was prepared comprising a hydrophilic component comprising 1) soap flakes 96.7%; 2) titanium dioxide 0.55%; 3) fragrance 1.65%; and 1.1% a hydrophobic component comprising i) beeswax; ii) sunflower oil; iii) chromium oxide green; wherein the ratio of beeswax:sunflower oil is about 1:1. The formulation is detailed in Table 1 below.

Embodiment 2

[0058] A cleansing bar composition was prepared containing a hydrophilic component comprising 1) soap flakes 96%; 2) titanium dioxide 0.5%; 3) fragrance 1.5%; and 2% hydrophobic components comprising i) beeswax; ii) sunflower oil; iii) chromium oxide green; wherein the ratio of beeswax:sunflower oil is about 15:85. The formulation is detailed in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com