Floating LNG storage and re-gasification unit and method for re-gasification of LNG on said unit

A regasification and floating technology, applied in the direction of container discharge method, mechanical equipment, container filling method, etc., can solve the problem of consuming large energy and extra waste gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

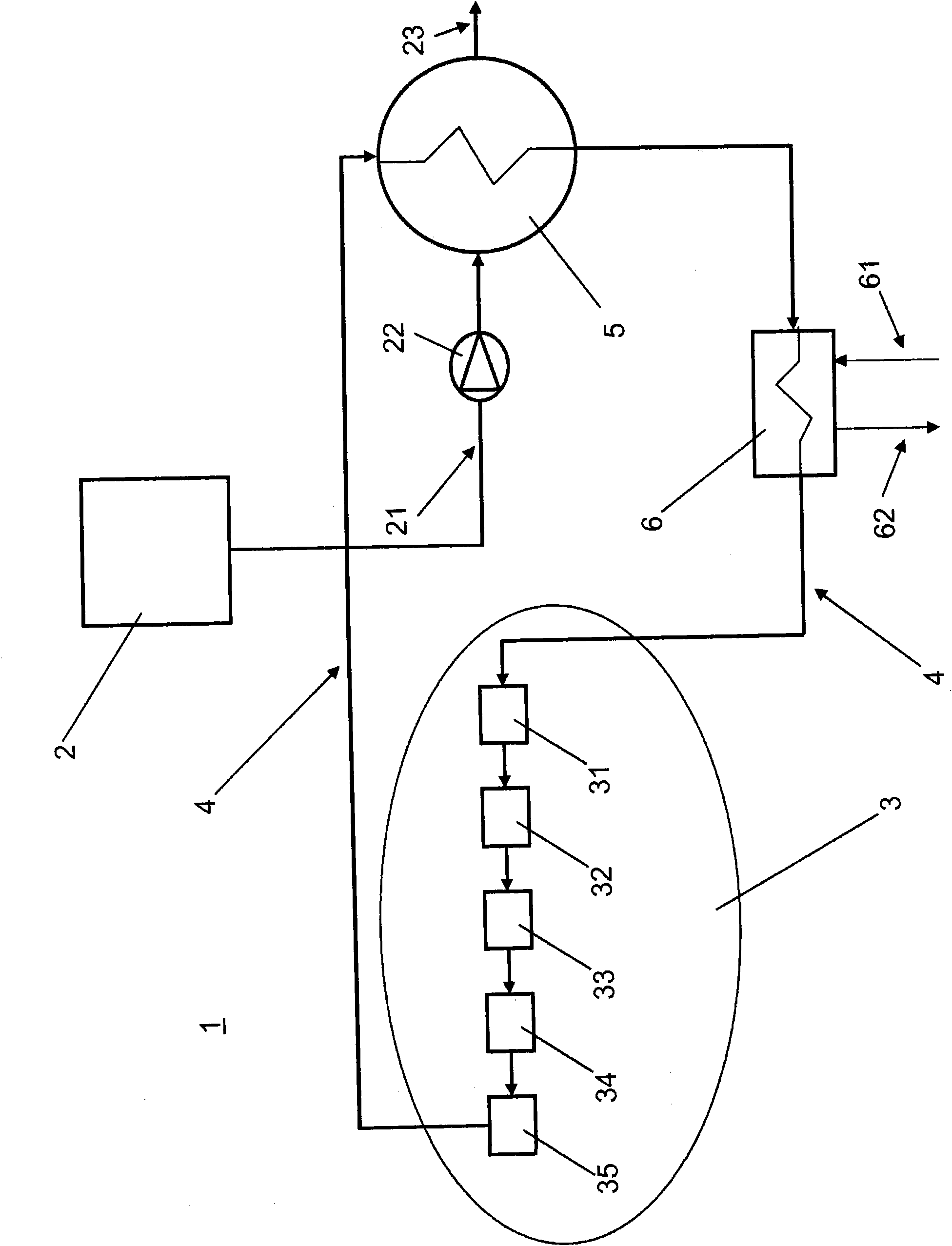

[0018] exist figure 1 In , the floating LNG storage and regasification unit (FSRU) is collectively denoted by reference numeral 1 . FSRUs are usually permanently moored terminals in the form of vessels without propulsion. The FSRU is provided with power generation equipment (in this embodiment, a power plant denoted by reference numeral 3 ), regasification equipment, hotel consumption equipment, and LNG storage equipment and LNG gasification equipment. The FSRU is also typically provided with a gas supply (not shown) for connection to appropriate pipelines for transporting the gasified LNG to shore and then to end consumption.

[0019] The FSRU includes an LNG storage tank 2 connected to a gasification device 5 through a supply line 21 provided with a high-pressure pump 22 . The gasification device 5 is provided as a heat exchanger for receiving LNG in liquefied form from an LNG storage tank and discharging it through a discharge line 23 after heating it into natural gas.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com