Machine tool for processing workpieces

A technology for processing workpieces and machine tools. It is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc. It can solve the problems of only small flexibility and limited processing space, and achieve the effect of modular structure and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

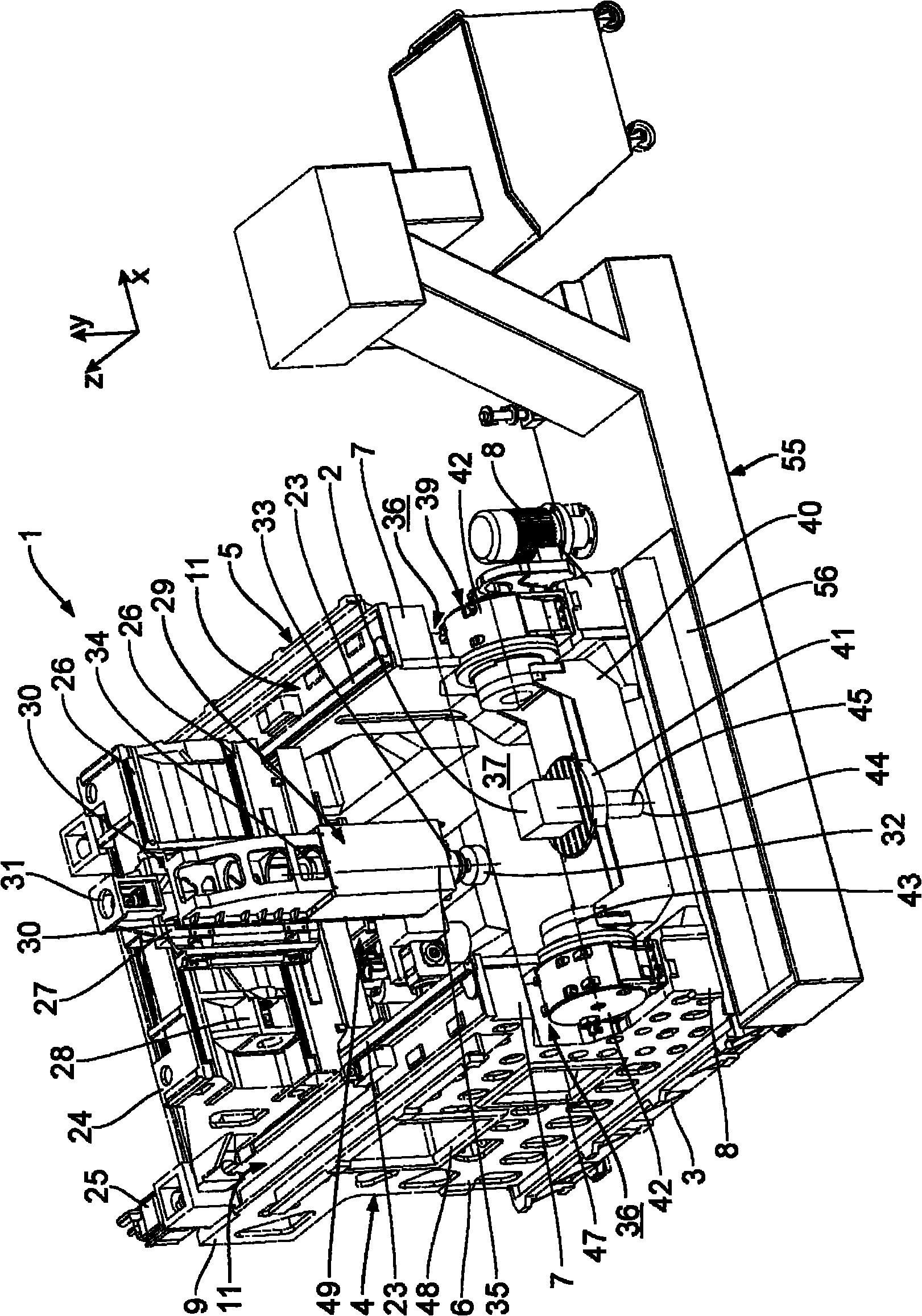

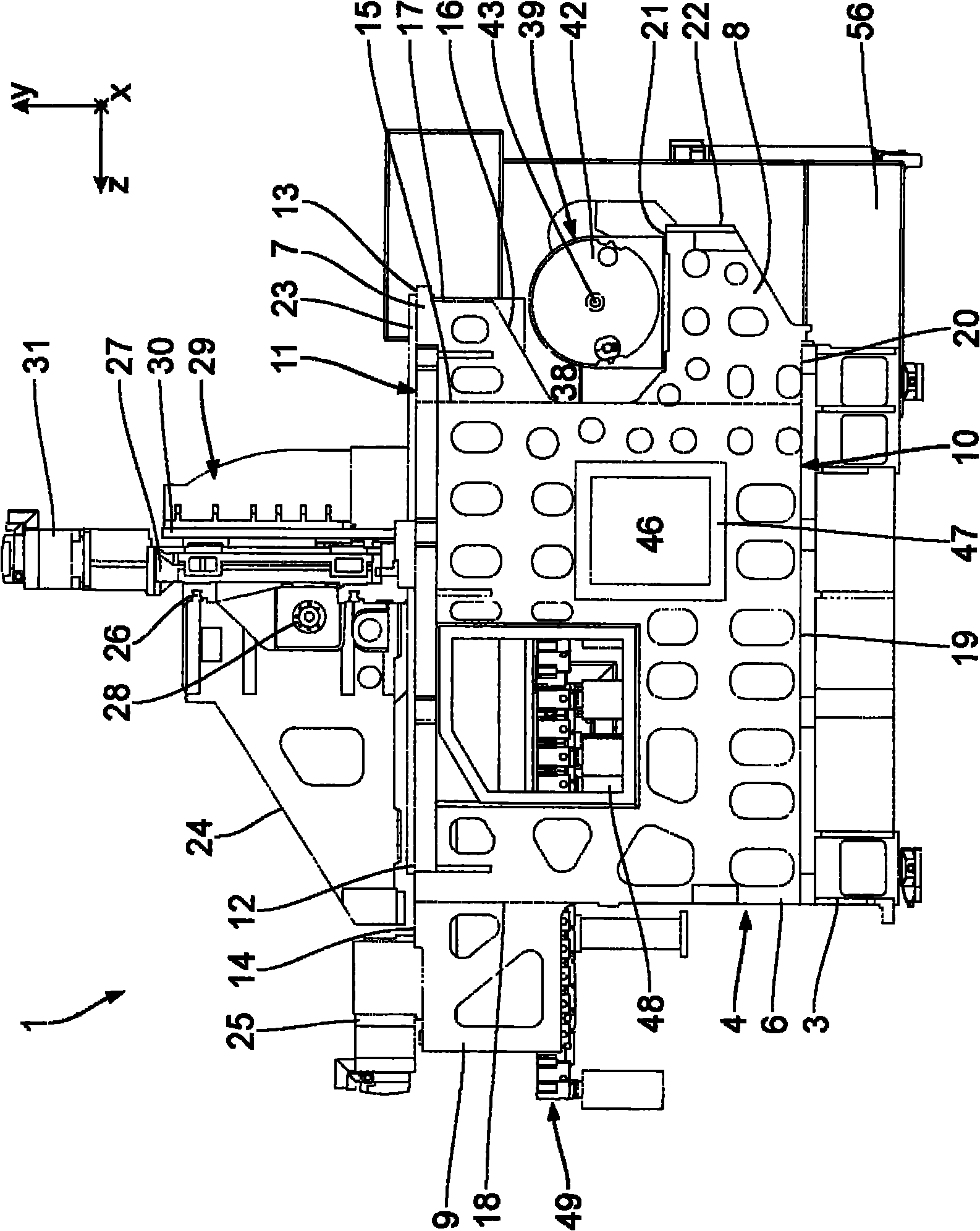

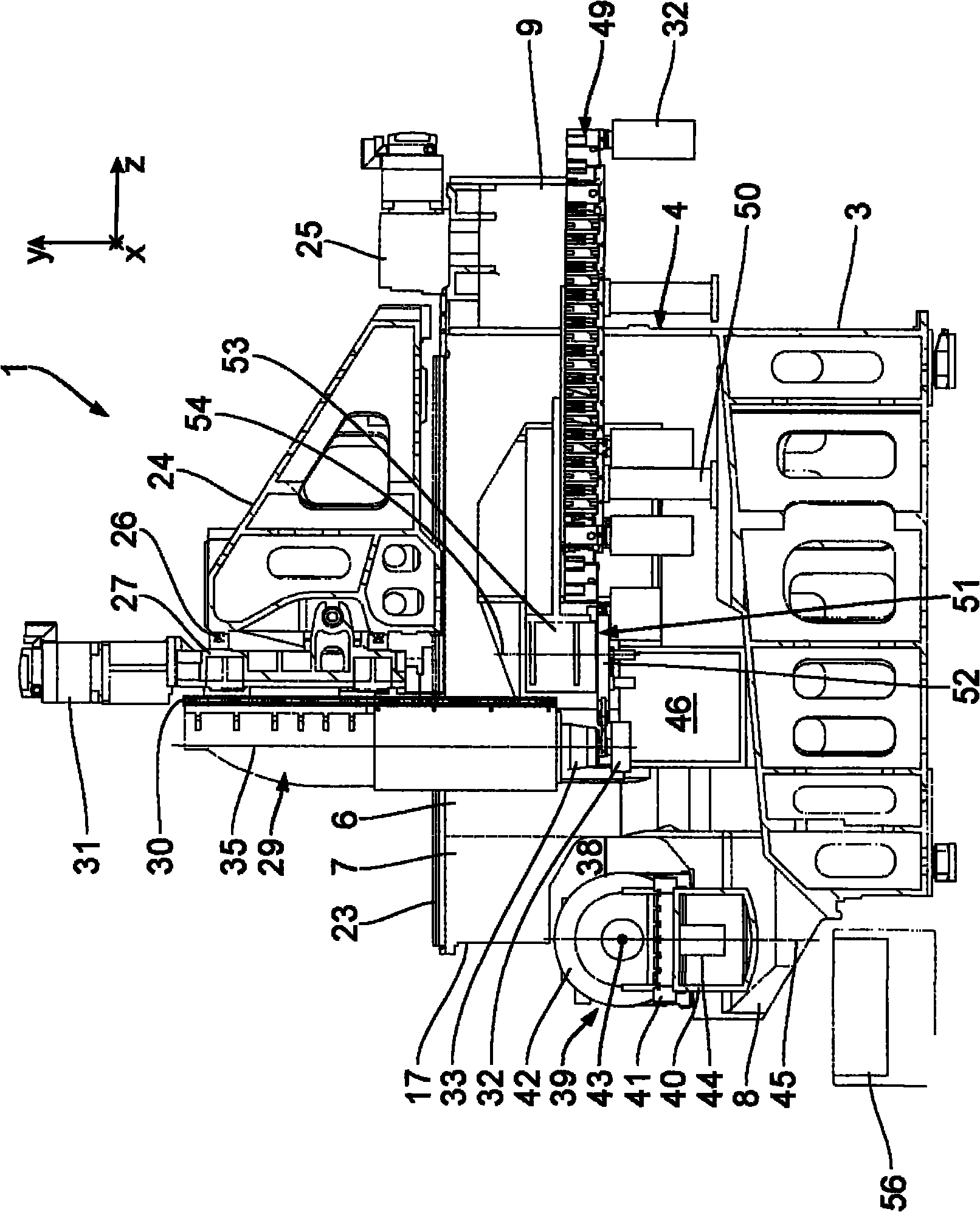

[0039] Refer below Figures 1 to 3 A first exemplary embodiment of the present invention is described. A machine tool 1 for machining a metal workpiece 2 comprises a machine base 3 on which a first side wall 4 and a second side wall 5 mirrored thereto are arranged. The side walls 4, 5 are spaced apart from each other in the horizontal x-direction and extend substantially parallel to a y-z plane defined by the vertical y-direction and the horizontal z-direction. The x, y, and z directions form a Cartesian coordinate system.

[0040] The side walls 4 , 5 each comprise a substantially rectangular base body 6 on which the displacement extension 7 , the bearing extension 8 and the support extension 9 are formed as one part. figure 2 By way of example, the rectangular base body 6 of the side wall 4 is shown in dashed lines. Each of the side walls 4 , 5 is fastened to the frame 3 via their side wall bottom side 10 . The side wall top side 11 remains free. Each side wall top sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com