Hydraulic generating unit

A technology of hydraulic power generation and power generation devices, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of being vulnerable to wind and water disasters, not easy to increase capacity, and high construction costs, so as to increase the normal service life and increase convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

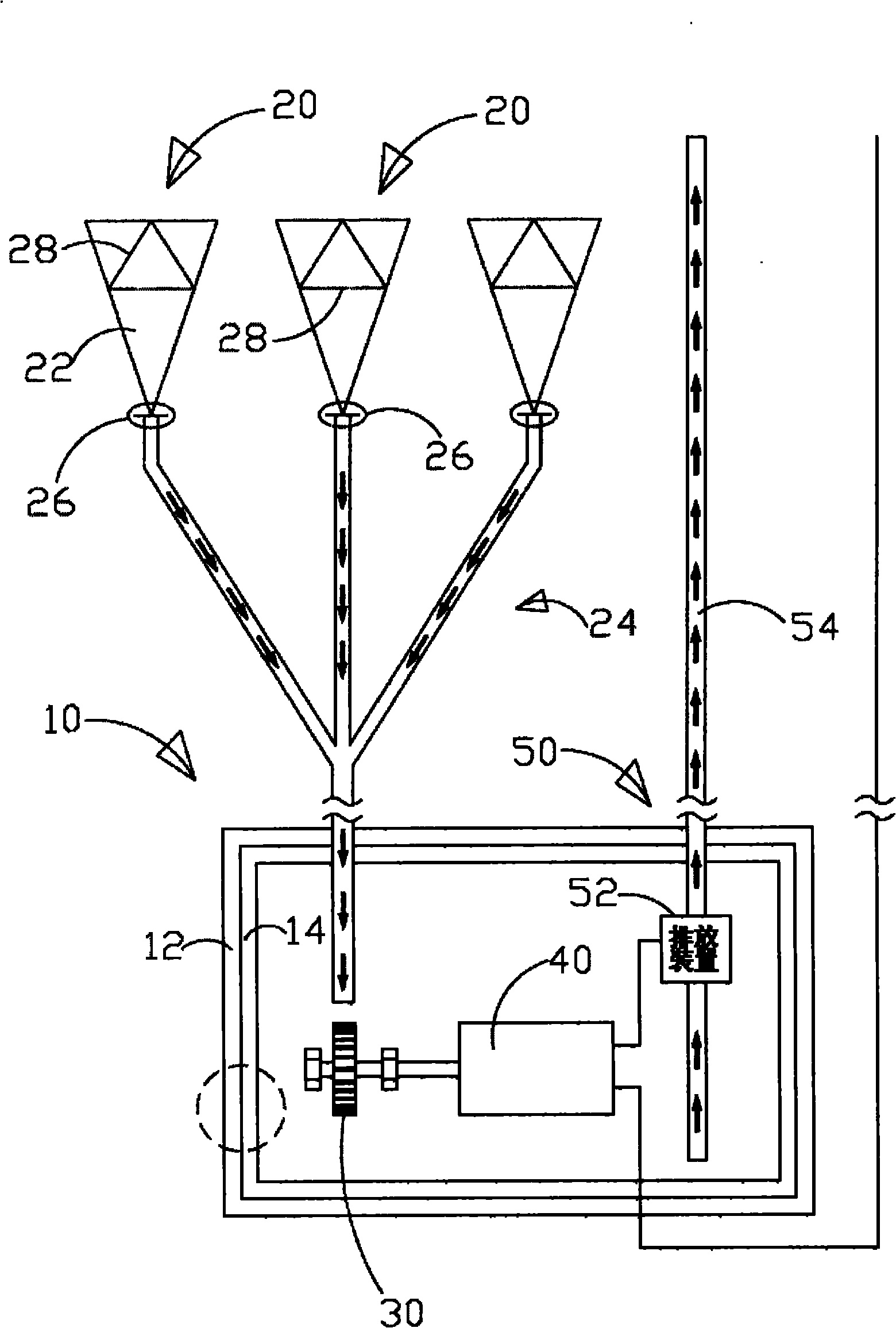

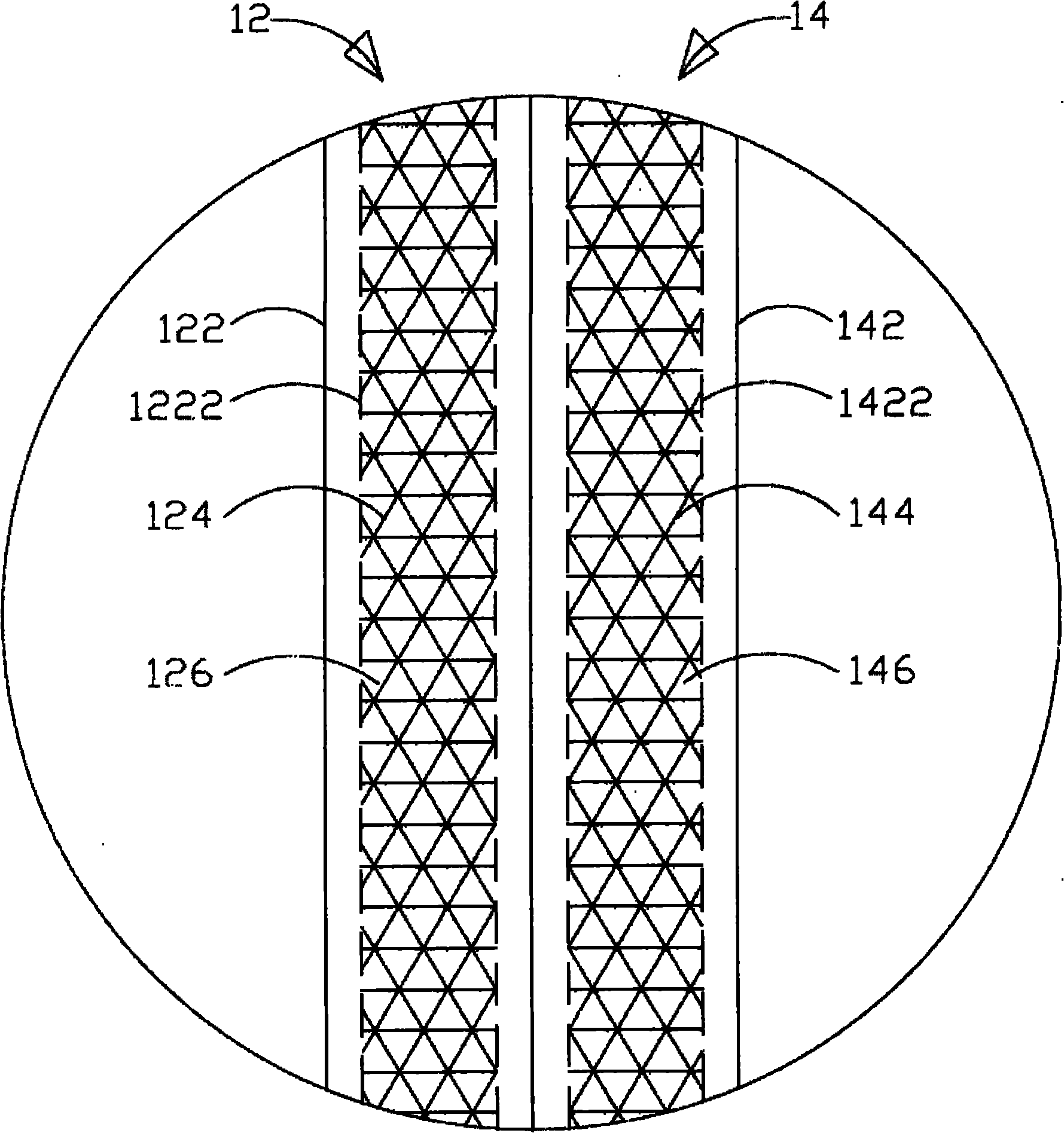

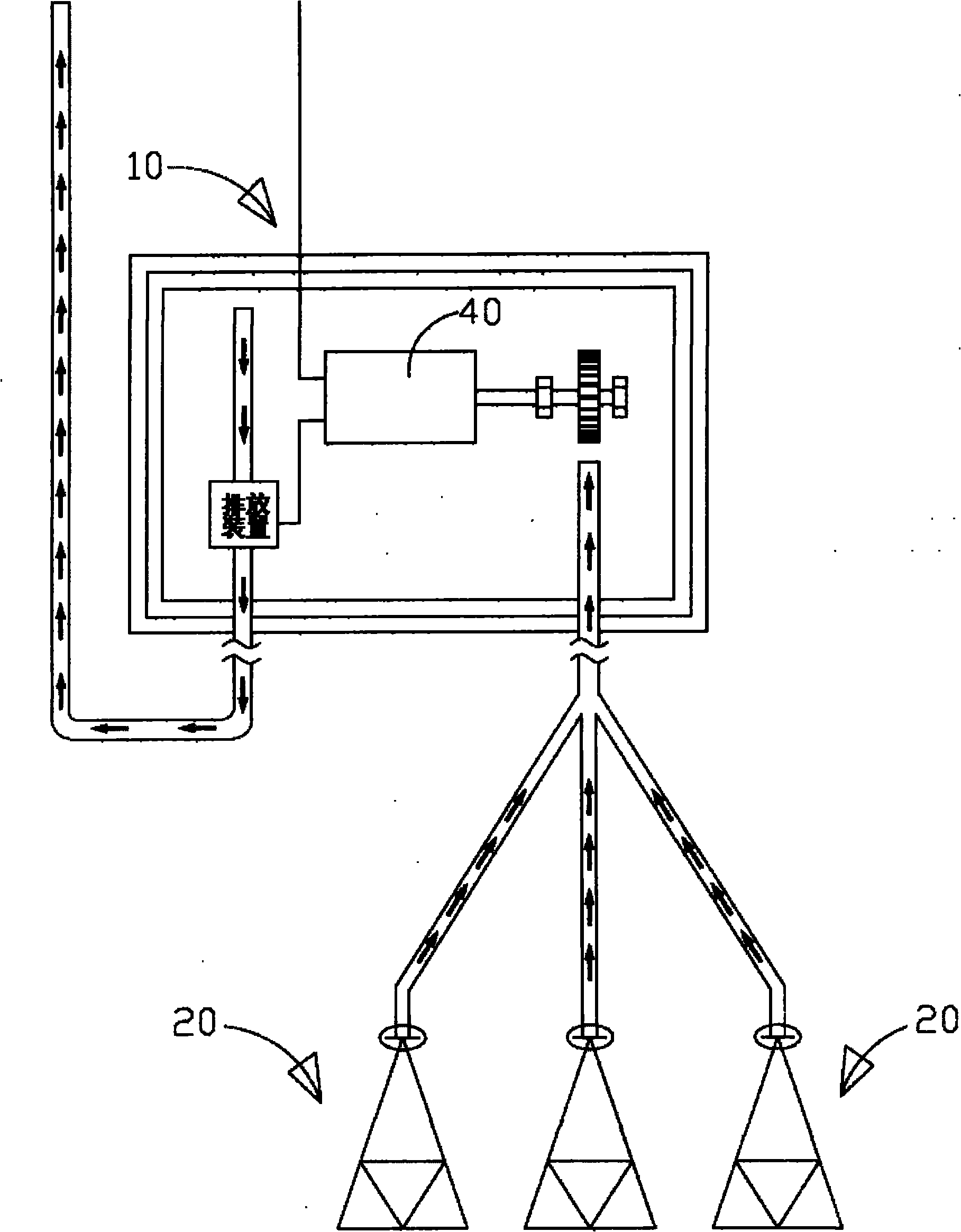

[0066] Please also refer to Figure 1A and Figure 1B , which is a schematic structural view of a hydraulic power generation device in a preferred embodiment of the present invention and a partially enlarged schematic view of a container; as shown in the figure, the hydraulic power generation device of the present invention includes a container 10, at least one collection device 20, a transmission member 30, A power generation device 40 and at least one discharge device 50, there is an air pressure in the container 10, the container 10 is arranged in a liquid, the collecting device 20 is also arranged in the liquid, the collecting device 20 is connected to the container 10, and the transmission part 30 is arranged in the container 10 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap