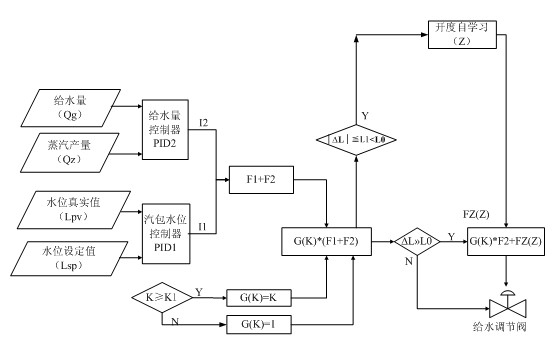

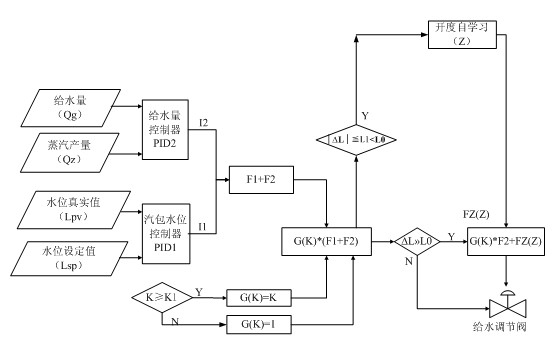

Drum level control system

A technology for controlling the water level of the system and steam drum, which is applied in the direction of controlling water supply, steam generation, preheating, etc., and can solve problems such as lack of water level trend, asymmetrical dynamic characteristic curve, system instability and oscillation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with specific embodiments.

[0053] The present invention adopts the following new ideas

[0054] (1) Water level change rate correction

[0055] The correction of the water level change rate is based on the finite principle of the disturbance change in the adjacent time period when the drum system is balanced, that is, the comprehensive influence of external factors such as steam production, water supply, steam drum pressure, valve response speed and pressure on the drum water level The effect will not change too much. By intercepting the water level change rate per unit time in real time, the change trend of the steam drum water level can be judged in advance and corrected in the control system, thereby improving the stability and safety of the system, and to a certain extent can prevent The generation of large water level fluctuations.

[0056] (2) Opening self-learning correction

[0057] When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com