Range hood

A technology for range hoods and smoke collection hoods, applied in the field of range hoods, can solve the problems of affecting the health of operators, failing to meet consumer needs, and losing the effect of collecting smoke, so as to improve the effect of oil separation and enhance the dynamic sense of technology , ingeniously designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

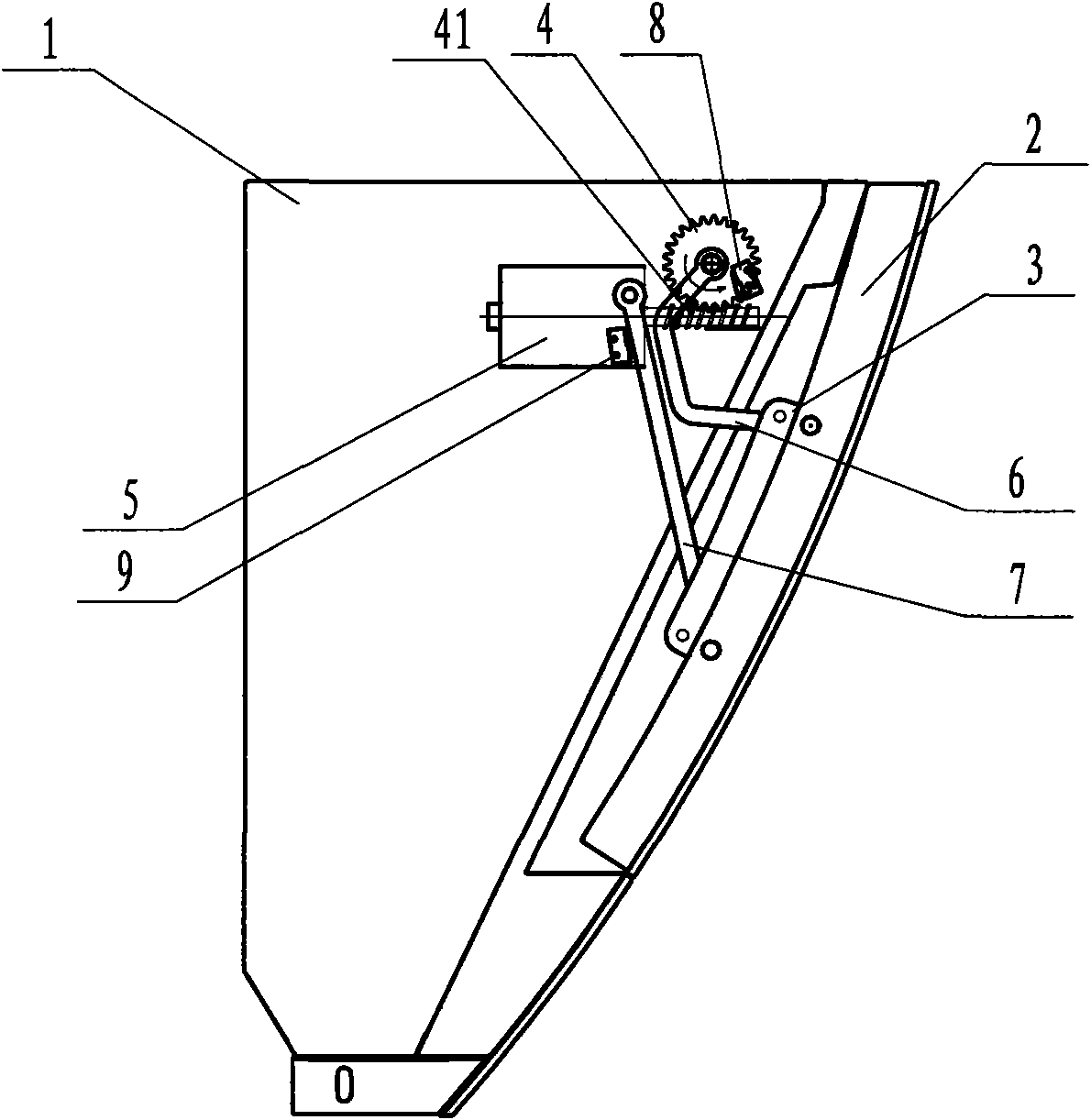

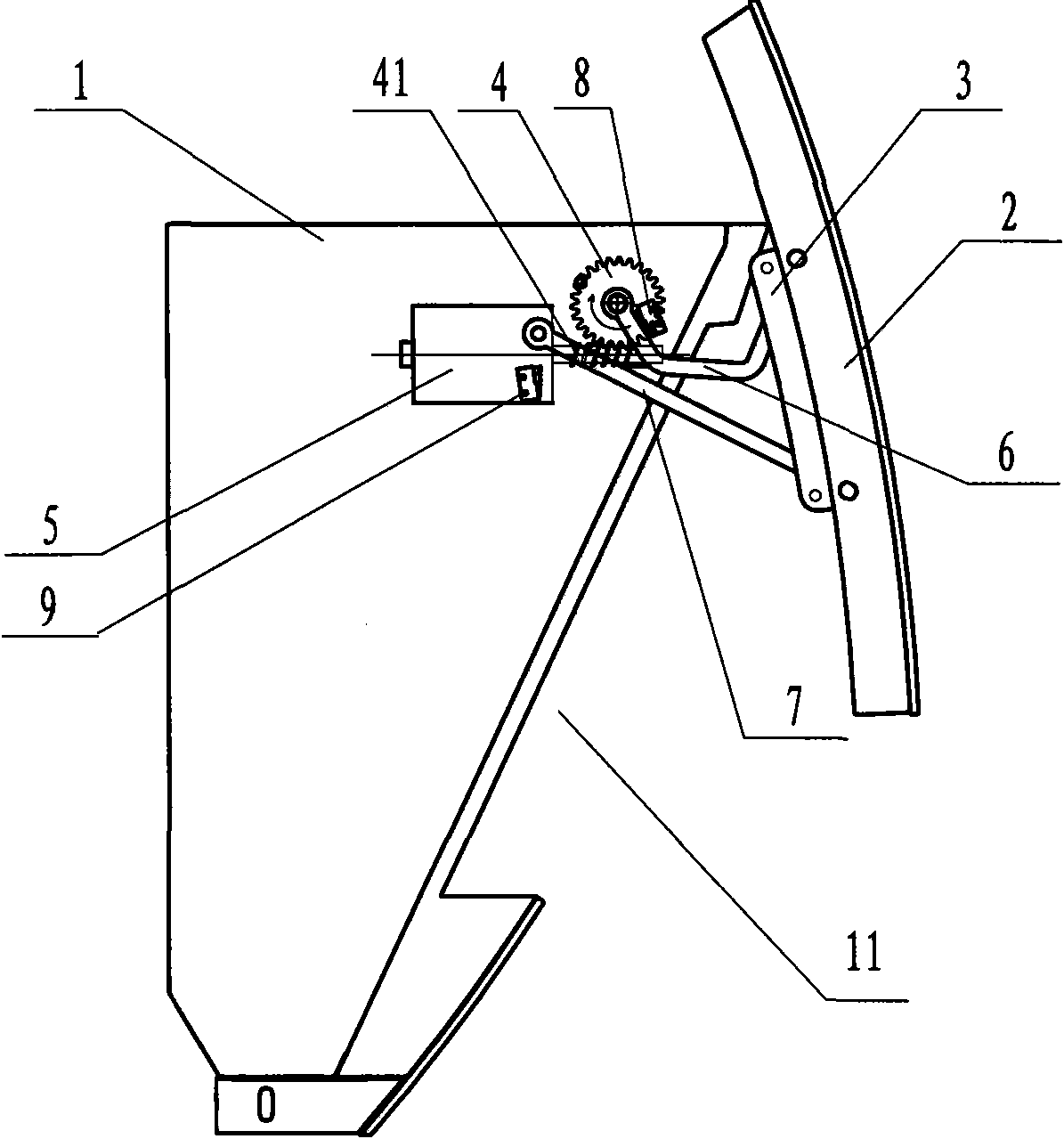

[0023] The structure diagram of the present invention is as figure 1 , 2 As shown, it includes a box body 1, a smoke collection hood 2 installed on the box body 1, wherein the smoke collection hood 2 is equipped with an air inlet 11, which can drive the range hood to move away from the box body 1 when it is working. When the range hood is not working, it can be driven back to the driving device on the box to cover the air inlet 11 of the box 1. The driving device includes a driving mechanism and a transmission mechanism. The driving mechanism passes through the transmission mechanism and the smoke collection hood 2 connect.

[0024] In the present embodiment, the above-mentioned driving mechanism is a reduction motor 5, and the transmission mechanism includes a turbine 4, a worm 41, a first connecting rod 6 and a connecting rod 3, wherein the turbine 4 is engaged with the worm 41, and the worm 41 is engaged with the reduction motor 5. One end of the first connecting rod 6 is...

Embodiment 2

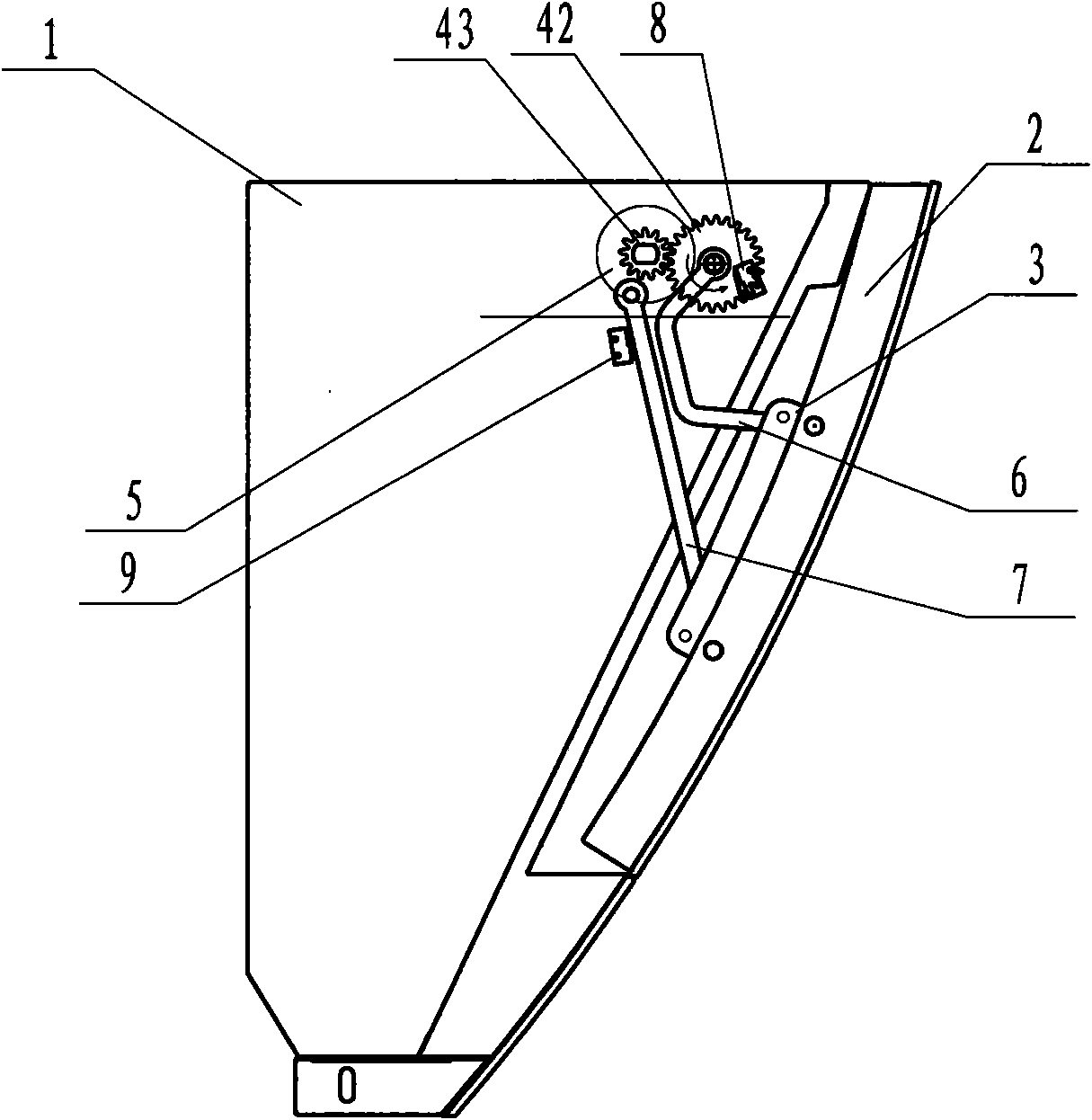

[0032] Such as image 3 , 4 As shown, the structure of the range hood in this embodiment is different from that in Embodiment 1 in that: the above-mentioned driving mechanism is a reduction motor 5, and the transmission mechanism includes a first gear 42, a second gear 43, a first connecting rod 6 and a connecting rod 3, wherein the first gear 42 meshes with the second gear 43, the second gear 43 is installed on the output shaft of the reduction motor 5, one end of the first connecting rod 6 is connected with the first gear 42, and the other end is hinged with the connecting rod 3, The connecting rod 3 is fixed on the fume collecting hood 2 . Other structures are the same as in Embodiment 1.

Embodiment 3

[0034] Such as Figure 5 , 6 As shown, the structure of the range hood in this embodiment is different from that in Embodiment 1 in that: the above-mentioned drive mechanism is an electric push rod device 10, and the electric push rod device 10 includes a drive motor 102, which converts rotational motion into linear motion The conversion mechanism and the push rod 101, the transmission mechanism includes the second connecting rod 7 and the connecting rod 3, the input end of the motion conversion mechanism is connected with the output shaft of the drive motor 102, the output end of the motion conversion mechanism is connected with one end of the push rod 101, The other end of the push rod 101 is hinged with the middle part of the second connecting rod 7 , one end of the second connecting rod 7 is connected with the box body 1 , and the other end is hinged with the connecting rod 3 which is installed on the smoke collecting hood 2 . The above-mentioned drive motor 102 is a DC s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com