Cleanroom system and cleanroom air-conditioning method

An air conditioning, clean room technology, applied in air conditioning systems, space heating and ventilation details, heating and ventilation control systems, etc., can solve the problems of high cost, high energy consumption, heavy workload of the cooling device 16, etc., to reduce Work load, high humidification efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, and characteristics of the air conditioning system and adjustment method for the clean room proposed according to the present invention will be described below in conjunction with the accompanying drawings and examples. and its efficacy are described in detail below.

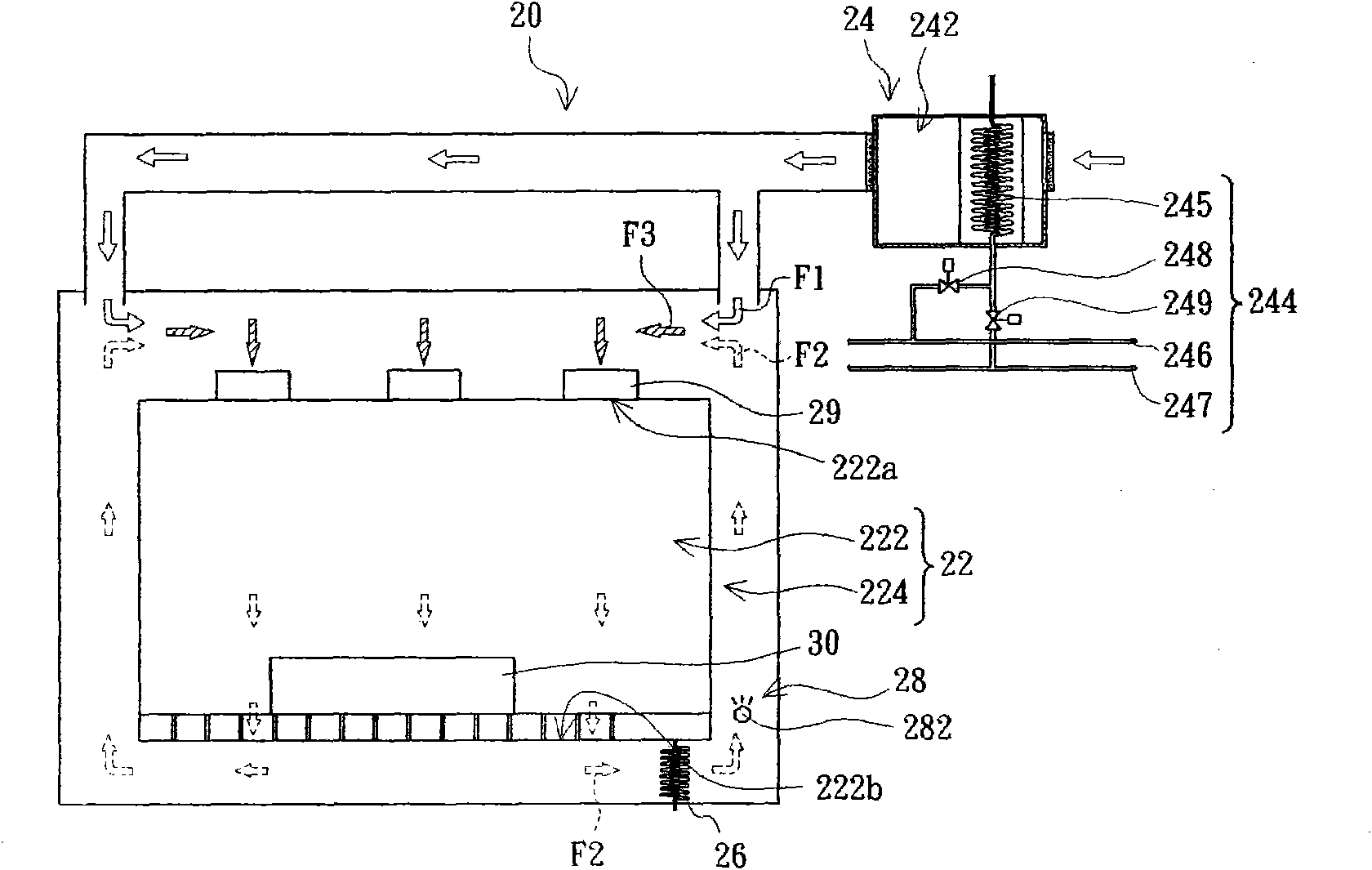

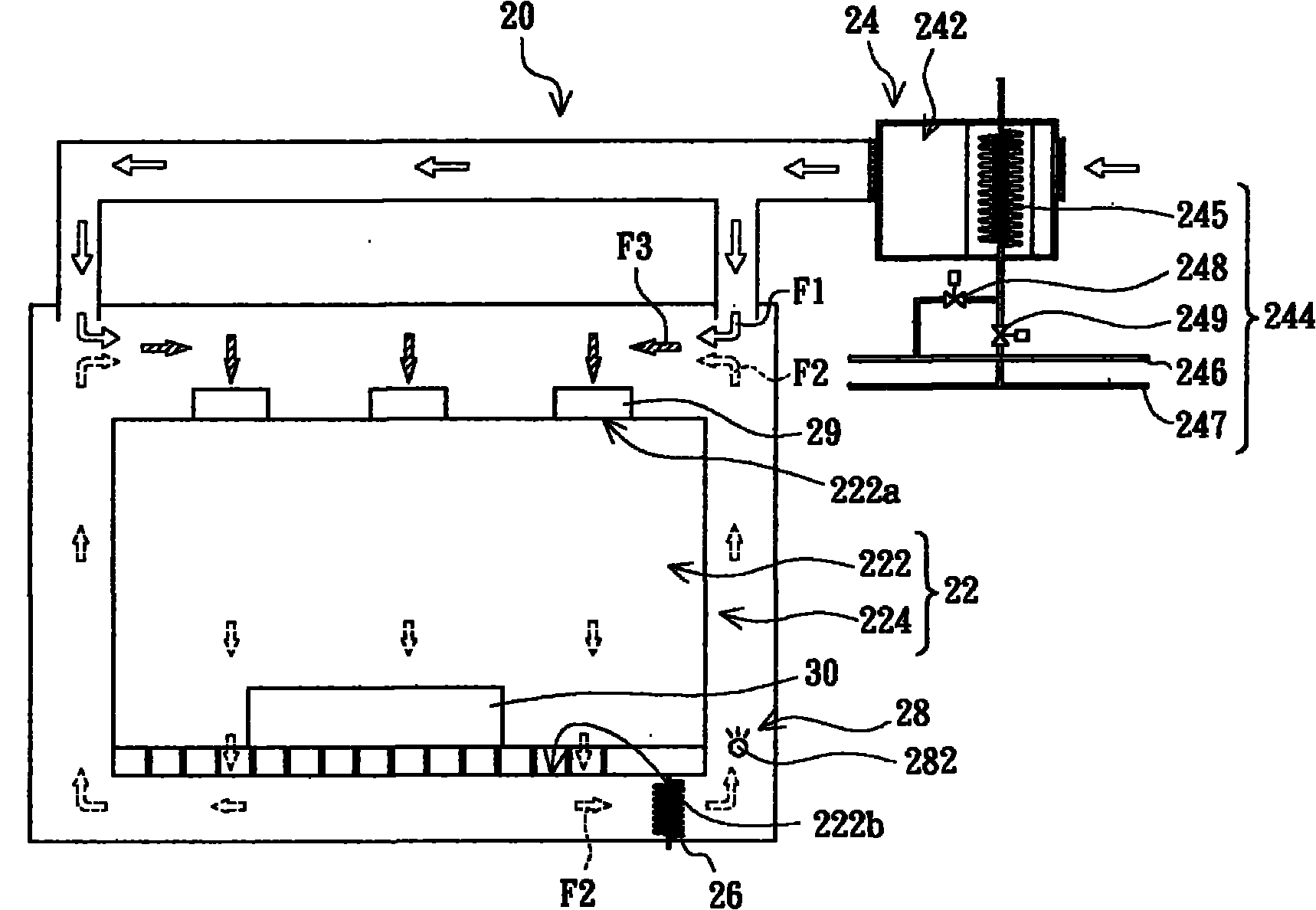

[0049] See figure 2 , The clean room system 20 of the present invention includes a clean room 22 , an air conditioner 24 , a cooling device 26 , a high pressure water mist humidifier 28 and a plurality of fan filter units 29 .

[0050] The clean room 22 includes a clean air room area 222 and a return air area 224 outside the clean air room area 222 . The clean air chamber area 222 has a plurality of air inlets 222a and a plurality of air outlets 222b. The return air area 224 communicates with the clean air chamber area 222 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com