Optical cavity for testing natural gas absorption spectrum

A technology of absorption spectrum and optical cavity, which is applied to the field of optical cavity for natural gas absorption spectrum test and optical cavity, and achieves the effect of simple structure, easy material and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

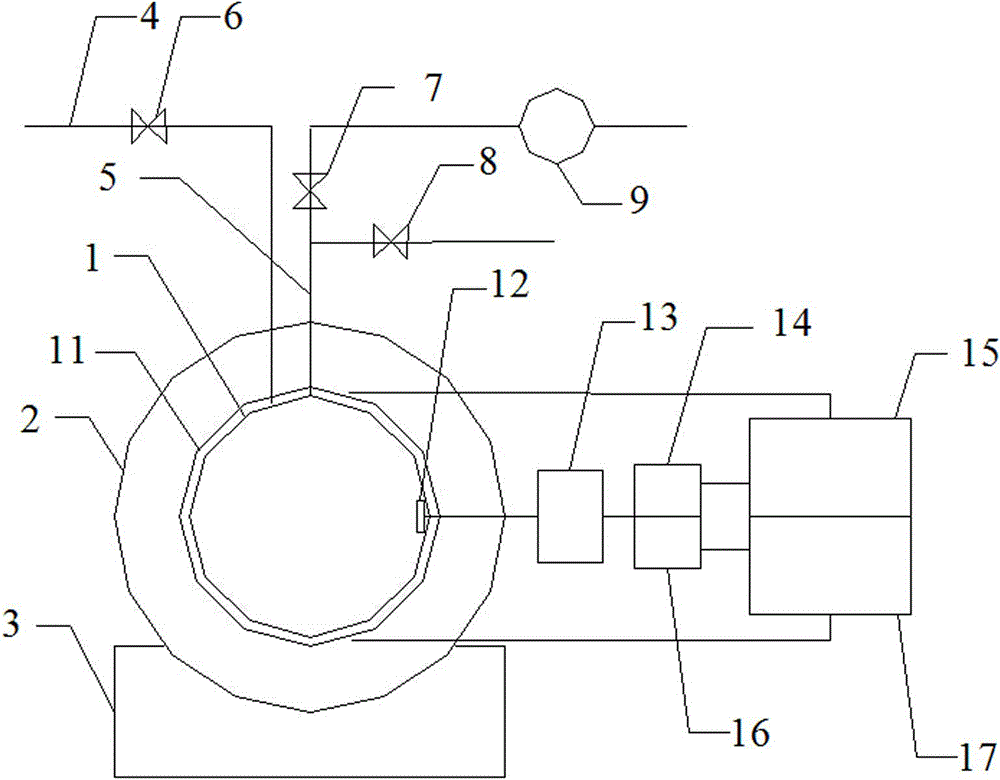

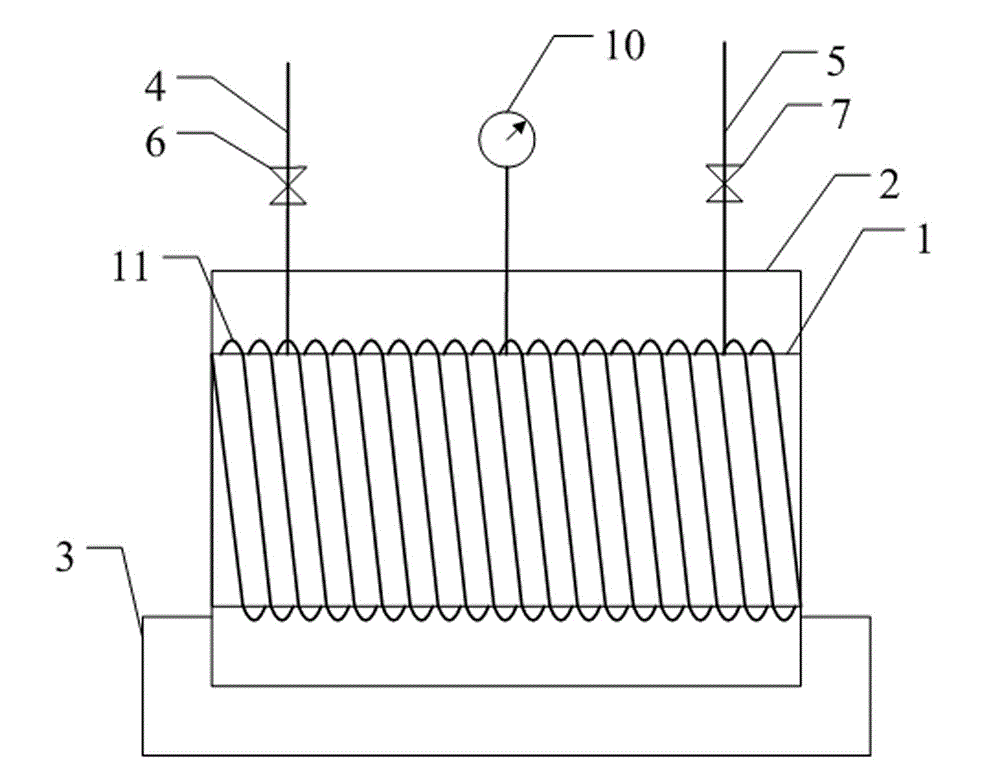

[0016] DETAILED DESCRIPTION One: This embodiment will be described with reference to the figures. The optical cavity for natural gas absorption spectrum testing of this embodiment includes an optical cavity. The optical cavity includes a measuring part, a gas filling part and a temperature adjusting part. The measuring part mainly includes Gas pool 1, insulation layer 2 and base 3; the charging part mainly includes an air inlet pipe 4, an exhaust pipe 5, an air inlet valve 6, a first exhaust valve 7, a second exhaust valve 8, a vacuum pump 9 and a pressure gauge 10; The temperature adjustment part mainly includes a heat exchange tube 11, a temperature sensor 12, a temperature controller 13, a heater 14, a water tank 15, a refrigerator 16 and an alcohol tank 17. A layer of heat exchange tube 11 is wound around the gas pool 1. The heat exchange tubes 11 are respectively connected to the water tank 15 and the alcohol tank 17, the gas pool 1 is covered with an insulation layer 2...

specific Embodiment approach 2

[0018] Embodiment 2: The embodiment is described with reference to the drawings. In this embodiment, the gas pool 1 is cylindrical, and the heat exchange tube 11 is a copper tube with a diameter of 2 mm, which is tightly wound on the side of the gas pool 1. The temperature adjustment media above 0℃ and below 0℃ are water and alcohol respectively. With this arrangement, the natural gas in the optical front can effectively exchange heat with the liquid in the temperature regulating tube, and the accuracy of the measurement can be achieved. The freezing point of alcohol is -117°C, and the boiling point of water is 100°C, which can greatly increase the temperature adjustment range, so that the gas in the optical cavity can be heated or cooled to achieve measurement at different temperatures.

specific Embodiment approach 3

[0019] Specific embodiment three: This embodiment is described with reference to the drawings. In this embodiment, the thermal insulation material is a non-combustible thermal insulation high-strength glass wool tube made of centrifugal glass wool material. The thermal insulation material is a non-combustible thermal insulation high-strength glass wool tube made of centrifugal glass wool material, which has many advantages such as flame retardant, non-toxic, corrosion resistance, small bulk density, low thermal conductivity, and strong chemical stability. It is currently recognized The most superior heat insulation and heat preservation material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com